Three different applications where PXI was an important part of the required test strategy and in some cases made the efforts easier

SHAUN FULLER & BOB STASONIS

NOVEMBER 2011: Every year products and systems with more intelligence and operational convenience are available; usually, at a lower cost than previous models. The basic premise of market-driven economies is the need to create new products that people will purchase.

As technology progresses, test-technologies and their implementation strategies change as well. The testing requirements these days include factors such as increased simulation of sensors, fault-insertion, higher data rates and increased precision. All of these must be accomplished while simultaneously increasing test throughput and lowering costs. While this has always been a tough challenge for the industry, it seems to be a more daunting prospect to support today’s technology.

Fortunately, the test and measurement (T&M) industry has been developing new solutions to address these needs. In many cases the solution has been PCI eXtension for instrumentation (PXI), which is a remarkably flexible platform. Over the last fourteen years, the 50-plus members of the PXI Systems Alliance (PXISA) have continued to innovate and create modules that can address the newest technologies.

Why PXI?

Many vendors, many more products, and lots of previous applications’ successes are key reasons for PXI’s success. But looking beyond, there are other reasons as well:

Choices in software. Many programming languages, including real-time operating systems as well as focused software for applications like hardware-in-the-loop simulation (HILS) make PXI implementation easier.

Connectivity. The best hardware is useless unless it can be connected to the unit-under-test (UUT). Fortunately, there are vendors who have created mass interconnects that work well with PXI.

Vendor creativity. The small size of 3U module (10×16 cm2) was seen as a detriment back in 1997 when the specification was released. It was felt that the small size, especially when compared to versa module europa (VME) eXtensions for instrumentation (VXI), would limit the bandwidth and density that could be achieved. But the naysayers were wrong! Switching densities of 4000 to 8000 relays in a single matrix, 1000V isolation, and RF instrumentation of 6 GHz and greater are just a few examples of what is possible in PXI.

Ability to work with other test platforms. In many instances, hybrid test systems are the norm. This can be due to the availability of test equipment, test budgets forcing hardware reuse, and partial re-hosting/upgrades of existing test systems. PXI has shown to work well in these environments.

System integrators. This segment of the test industry has embraced the PXI platform as a solution for many applications. Their ability to make PXI work is a big part of the success.

How PXI has been employed?

Let’s look at applications where specialised simulation of a UUT’s operating environment is necessary for test. Every test system is a simulator, as the system replicates the car, PC or the missile that the UUT will ultimately end up in. But new applications require new simulation techniques.

Here we discuss several applications where PXI was an important part of the required test strategy and in some cases made the efforts easier. Some of these applications are unique enough and one might think these would not require advanced testing techniques, much less any simulation. But in each case, PXI was a major portion of the test strategy.

1. Automotive ECU fault insertion

Customer. A leading French systems integrator who develops functional and design validation testers for the automotive and aerospace industries.

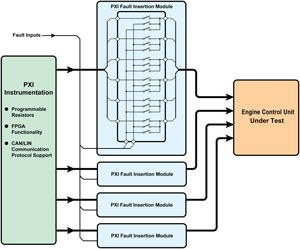

Application. The end-user required test systems to validate the design reliability of their engine control units—also known as power-train control modules or engine control modules.

The system integrator was tasked to find a more flexible and cost-effective alternative to proprietary HILS solutions. The existing system was an internally-developed design and used a very manual method of performing fault simulation. To insert a fault, the operator had to manually move cables on a patch panel to short pins together, force a stuck at Vbat or ground, or inject false sensor data. This method was slow, subject to human error and expensive. Given the issue of liability when electronic systems fail and the continuous pressure to lower costs, a strategy change was clearly necessary.

Fault simulation during the design and validation of ECUs is a method of establishing solid predictions for reliability and firmware verification, ensuring the safety of driver and passengers. An ECU relies on information from a set of sensors and controls to decide what to do with the device that it is managing. These sensors often work in extremely hostile environments (such as within a car in this application) and predictable failures can occur in the sensors or their interconnections. The ECU has to respond appropriately to these component failures, as well as to genuine system faults.

The idea of testing for system failures is not new. It is an important aspect of ECU validation and involves the introduction of electrical faults into a system. The test process typically duplicates various conditions that could occur because of corrosion, short/open circuits and other electrical failures inherited through infant mortality, age, damage or even faulty installation.

Solution. PXI provides an open platform for HILS requirements. Combining this with the large range of hardware available from vendors enables flexible and cost-effective alternatives to proprietary systems.

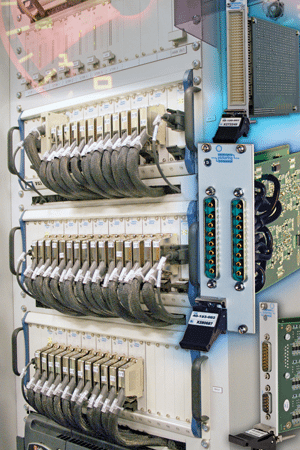

The modularity and openness of PXI enabled the integrator to design a highly scalable solution with plenty of potential for evolution.