The first thing you need to look at while buying a digital multimeter (DMM) is the environment in which you will be using it and the required safety ratings. DMMs are designed with different levels of protection, so ensure the one you have selected withstands the electrical hazards in your working environment.

Next, list down the features you really need and the ones you desire as a bonus. Think about whether you just need to take basic measurements, or you also need the more advanced troubleshooting options offered as special features. Selecting a device with more capabilities than you need means spending more money unnecessarily.

Last, you need to finalise the measurement ranges for each quantity and other technical specifications. The measurements need to be accurate for all engineering jobs as your analysis will depend entirely on the measured value. But, if due to lack of understanding of the technical specifications, you take the measurements with a wrong DMM, you can never get the correct measurements.

Safety first

Safety is normally not given due consideration while selecting a DMM. Different DMMs are designed for different environments and they will not have the same level of protection against common electrical hazards. For this reason, one of the most important considerations in selecting a handheld DMM is thorough understanding of the test environment and test requirements.

Now the obvious question is: How do the measurement environments become different from one another? There are three key factors that differentiate these: voltage rating, transient voltage rating and energy capacity of the circuit.

Voltage rating. Different electrical equipment have different operating voltage ranges. For example, the supply voltage for equipment on trains in Indian railways is 110V DC but our home appliances work with 230V AC. So it is important to identify the maximum voltage at which the circuit is designed to work and choose a handheld DMM rated to measure that voltage.

Transient voltage. As distribution systems and loads become more complex, the possibility of transient over voltages increases. If you are taking measurements on electrical systems, these transients are invisible and largely unavoidable hazards. They occur regularly, can reach peak values in many thousands of volts and can last from 50 to 200 microseconds.

Transient voltages can result from natural causes, such as lightning, or can be generated by switching operations on the power distribution system.

Energy capacity. It is the most important consideration for safety in addition to the transient voltage. The energy capacity is defined by three characteristics: operating voltage, circuit impedance and the characteristics of the circuit fuse or circuit breaker.

It is important to find out the energy capacity of a particular circuit before you take any measurements. Otherwise, you might blow the DMM in your hands.

Measurement categories

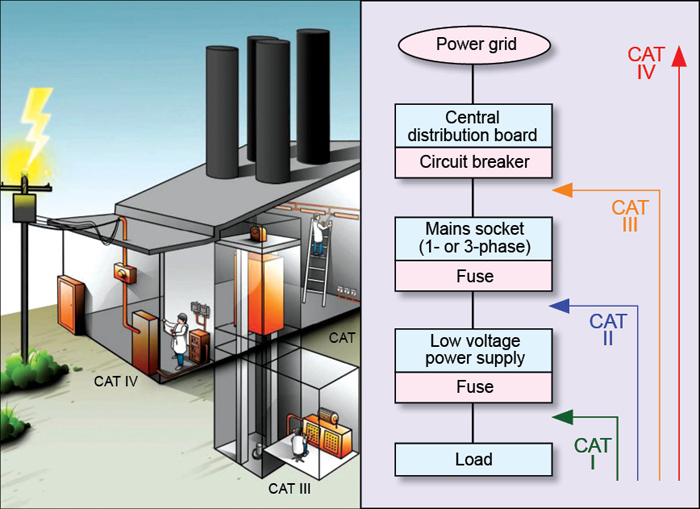

The International Electrotechnical Commission (IEC) has defined the ‘measurement categories’ for mains circuits. Categories are defined by probability of over-voltage. Higher the over-voltage, higher the category number, and the danger posed by transient voltages.

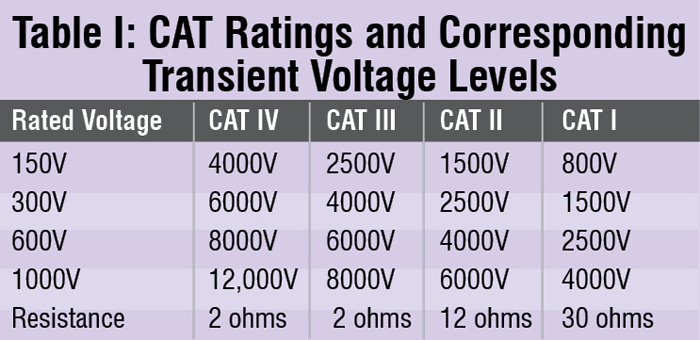

All manufacturers of handheld DMMs are required to mention the rated measurement category on their products. This marking is a convenient way for users to identify the maximum transient voltage that the device can safely withstand. Most handheld DMMs display this rating near the voltage/current input terminals. CAT III is the one you will generally find on the DMMs but, beware, some cheap Chinese multimeters write CAT III just like that, because they know what users are looking for. Table I shows the different categories and the related transient voltages.

All manufacturers of handheld DMMs are required to mention the rated measurement category on their products. This marking is a convenient way for users to identify the maximum transient voltage that the device can safely withstand. Most handheld DMMs display this rating near the voltage/current input terminals. CAT III is the one you will generally find on the DMMs but, beware, some cheap Chinese multimeters write CAT III just like that, because they know what users are looking for. Table I shows the different categories and the related transient voltages.

All categories only apply to low voltage (CAT II-1000V is not safer than CAT III-600V instrument. They both provide protection up to the same level (6000V). But CAT III-1000V is safer than CAT III-600V. It is important to note here that all DMMs are only designed to measure nominal steady-state voltages continuously while also being able to withstand a momentary high transient. They cannot withstand a continuous over-voltage condition.

Features

The DMMs have a variety of features and it is important that you first know what exactly they are. Other than the basic measurement functions, the features mentioned below can be useful but they come with additional cost.

Auto range with manual override. In manual range DMMs, you are required to set the range before taking any measurement, which is very tedious. There is also a possibility that you may not know the range every time. And if you take the measurement selecting a wrong range, you might not get the correct measurement, instead there is a high chance of the meter getting damaged.