Why is the LED lighting industry abuzz with light-emitting diode chips on boards (LED)? What makes these the current favorite? Which applications are these good for and for which ones should these be avoided? Most importantly, what are the factors based on which you should choose the right LED COB chip? These are some questions I have tried to answer here.

Technologies Galore

Before we get down to discussing the parameters based on which you should choose your LED chip—mainly COB LED—let me give you a perspective of the different technologies that power different types of LEDs.

DIP LEDs: Dual inline package (DIP) LED technology, as shown in Fig. 1, is likely what you think of when you picture a LED. It has been around for more than 50 years. Though it is old, DIP LEDs are far from outdated as these are still used extensively for large signs and displays.

These LEDs are typically found in electronic and electrical gadgets as indicator lights because of their low cost, high brightness, and ease of installation. DIP LEDs generally produce between three lumens and four lumens per LED.

SMD LED chips: SMD or surface-mounted devices or chips (Fig. 2) have become very popular due to their versatility. These are much smaller in comparison to DIP. SMD LEDs have been used to create everything from light bulbs to strip lights.

SMD chips have the ability to put three diodes on the same chip. When a chip includes a red, green and blue diode, you have a chip that can create any colour you want by adjusting the level of output from each individual diode on the chip. Because these are bright and can change colours, these chips are used extensively for LED strip lights and light bulbs.

COB LEDs: COB chips have multiple diodes (more than three) on the same wafer. This is where the similarities between SMD and COB end. In fact, on every COB chip (Fig. 3) there are multiple diodes.

While SMD requires a circuit for every diode included on the chip, a COB device has only one circuit with two contacts for the entire chip, regardless of the number of diodes. This single-circuit design, regardless of the number of diodes on the chip, leads to design simplicity.

More importantly, LED COB has improved lumen-per-watt ratios in comparison to other LED technologies such as DIP and SMD. Unfortunately, the big drawback of COB (due to single-circuit design) is that multiple channels are necessary to adjust individual levels of light output to create colour-changing effects. Thus, LED COB lighting is powerful and efficient for single-colour applications, but cannot be used to create colour-changing lights.

LED COB chips vary widely in their applications and thus different chips require different wattage, voltage and produce vastly different lumen counts. However, LED COB chips have good lumens per watt ratio, starting typically from 80 lumens per watt minimum and going up to 100 lumens per watt or more. This attribute of high efficiency makes these a clear favourite for all applications running on batteries, including mobile phones, cameras and more.

MCOB LEDs: A variant of COB is now gaining popularity—MCOB or multiple chip on board. MCOB devices (Fig. 4) are very similar to COB chips in their application and are essentially multiple COB chips together in series. MCOB devices produce a lot of light and are even better than COBs for low-wattage applications. MCOB is a very new technology at this point that not many manufacturers are producing, but will likely catch on.

Why COB LEDs?

From the above, it is clear that COBs are one of the best options available. These promise to lower the overall cost of LED luminaires by providing several benefits, such as greater design flexibility, better light distribution and simpler manufacturing process. Here is why:

1. COBs produce less heat as compared to other forms of LEDs. This, in turn, results in higher efficiency. Better thermal dissipation is achieved because the LEDs are directly mounted on an aluminium sheet, which, in turn, offers better heat dissipation as compared to other materials.

2. COBs have a lower failure rate because spot soldering is no longer required as it is built directly onto the PCB.

3. Another major factor is that, typically COBs have a much wider beam angle and thereby a higher colour rendering index (CRI). This makes these a preferred choice for outdoor lighting luminaries such as streetlights.

4. It is also possible for COB LED package to be assembled in the heat sink directly. In such a scenario, a separate mounting and PCB are not required.

How to choose the right LED COB package

Let us now discuss some of the parameters that are important while choosing COB LEDs:

Forward voltage: This is the amount of volts the LED requires to conduct electricity and light up. A typical 20-watt COB LED would require a forward voltage of about 29V DC to 32V DC.

Forward current: It is the current flowing through an LED when forward voltage is applied to it. A typical 20-watt COB LED draws about 640mA. Therefore you should choose the appropriate current driver as per the rating on the LED package.

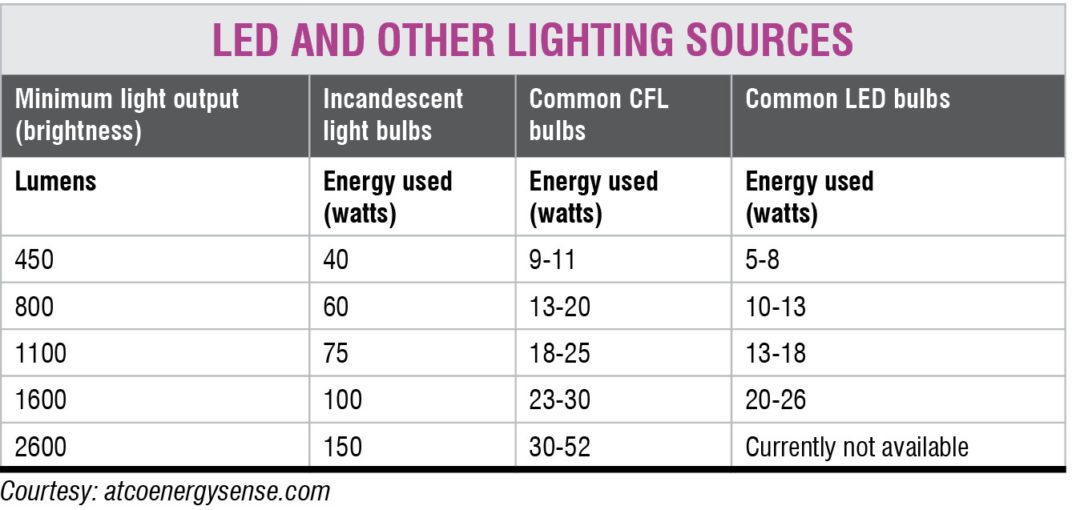

Power consumption: An LED lamp packaging may be specified with power consumption in watts, lumen output, colour temperature, operating temperature range and others. Power rating in LED lamps should not be confused with power ratings in other lighting systems. With less wattage rating in LED lamps, as compared to other lighting products, you can get more light output or lumen output as shown in the table on the previous page.

Luminous flux: It is used as an objective measure of the total amount of visible light that your lighting source produces. The SI unit of luminous flux is lumen (lm). If you compare a CFL and a normal white LED, the latter is highly energy efficient and uses very little energy.

The lumens produced by an LED bulb as compared to other lighting sources are shown in the table. COB LED offers a greatly improved lumen-per-watt ratio compared to other LED technologies.

Efficacy: This parameter is for deciding the performance of the LED. It is the effectiveness of the LED at converting electricity into visible light. Thus, efficacy is total lumens per watt. For example, if a nine-watt light bulb comes with lumens of 800, it means it has an efficacy of about 90 lumens per watt.

CRI, or colour rendering index. CRI is a measure of light quality, showing how well a light source replicates colour to the human eye. White light is made up of all the colours in the light spectrum. We can see the colour of every material object in daylight. Natural daylight has the highest CRI rating, while artificial light sources cannot produce all the colours of the light spectrum. CRI of 80 is the standard requirement for general home use.

CCT, or correlated colour temperature: CCT is measured in Kelvin (K) to refer to the warmth or coolness of the white light that the LED produces. The higher the temperature, the cooler the light looks. An LED bulb marked with 5000K does not actually heat up to 8500°F, but still gives off a warm light.

Some LED bulbs have more than 6000K CCT, which makes the light more towards bluish rather than white. A warm light is around 2700K, while neutral white at around 4000K and cool white at 5000K or more.

Lifespan of LED COB: Another important specification is the lifespan in hours. Some LED lamps may last for 50,000 hours. So if you consider daily use of eight hours, it may last 17 years.

Life of the LED also depends on the heat-sink used. COB technology gives the best conditions for optimal cooling, which, in turn, increases efficiency and lengthens the overall life of the lamp.

Beam angle: Beam angle of a bulb refers to the spread of light to your surroundings. For example, a spotlight in a kitchen will have a beam angle of between 35 degrees and 60 degrees. Standard and candle-shape bulbs require a beam angle as wide as possible when fitted to lamps. Though, ideally the beam angle should be over 200 degrees.

To distribute light better, to more areas, you would need a wider beam angle. But a narrow beam angle is required when you want to have the light more focused and intense. Adjusting beam angles correctly can vastly improve the lighting effect in a room.

Junction temperature: It is the highest operating temperature of the actual semiconductor in an electronic device. This temperature is normally specified in the datasheet. You will require this value when calculating the case-to-ambient thermal resistance for a given power dissipation. This will help you select an appropriate heat-sink.

COB LEDs are going strong

Many publicly available industry reports claim that there is an increasing demand for COB LEDs in the global lighting industry. As of now, you can see LED COB in many consumer and industrial products including bulbs, downlights, tube lights, street lamps, bay lights and others. One can confidently state that their future looks bright, for now.

For reading other exciting LED-related articles: click here

Sani Theo is senior assistant editor – tech at EFY