This sensitive mechanical vibration sensor is exclusively made for shops to protect against burglary. It will detect any mechanical or acoustic vibration in its vicinity when somebody tries to break the shutter and immediately switch on a lamp and sound a warning alarm. A 15-minute time delay after switch-on allows sufficient time for the shop owner to close the shutter.

This sensitive mechanical vibration sensor is exclusively made for shops to protect against burglary. It will detect any mechanical or acoustic vibration in its vicinity when somebody tries to break the shutter and immediately switch on a lamp and sound a warning alarm. A 15-minute time delay after switch-on allows sufficient time for the shop owner to close the shutter.

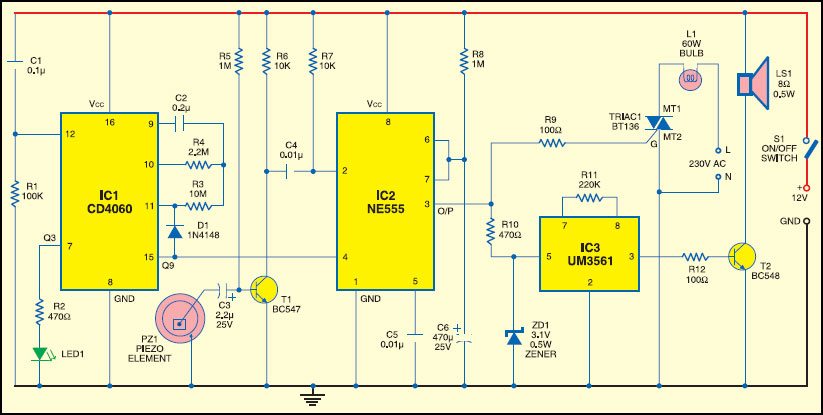

Mechanical vibration sensor circuit

The front end of the circuit has a timer built around the popular binary counter IC CD4060 (IC1) to provide 15-minute time delay for the remaining circuitry to turn on. Resistors R3 and R4 and capacitor C2 will make Q9 output high after 15 minutes. Diode D1 inhibits the clock input (pin 11) to keep the output high till the power is switched off. Blinking LED1 indicates the oscillation of IC1.

The high output from IC1 is used to enable reset pin 4 of IC2 so that it can function freely. Transistor T1 amplifies the piezo-sensor signal and triggers monostable IC2. The base of transistor T1 is biased using a standard piezo element that acts as a small capacitor and flexes freely in response to mechanical vibrations so that the output of IC2 is high till the prefixed time period.

In the standby mode, the alarm circuit built around IC3 remains dormant as it does not get current. Timing components R8 and C6 make the output of IC2 high for a period of three minutes.

When any mechanical vibration (caused by even a slight movement) disturbs the piezo element, trigger pin 2 of IC2 momentarily changes its state and the output of IC2 goes high. This triggers triac 1 and the alarm circuit activates. Triac BT136 completes the lamp circuit by activating its gate through resistor R9. IC UM3561 (IC4) generates a tone simulating the police siren with R11 as its oscillation-controlling resistor. Zener diode ZD1 provides stable 3.1V DC for the tone-generating IC.

Construction & testing

Assemble the circuit on a general purpose PCB and enclose in a suitable, shockproof case. Connect the piezo element to the circuit by using a single-core shielded wire. Glue a circular rubber washer on the fine side of the piezo element and fix it on the shutter frame with the washer facing the frame so that the piezo element is flexible to sense the vibrations. Fix the lamp and the speaker on the outer side and the remaining parts inside the case. Since triac is used in the circuit, most points in the PCB will be at mains lethal potential. So it is advised not to touch any part of the circuit while testing.

The article was first published in September 2007 and has recently been updated.