The instruments we see today were either non-existent or worked very differently ten to fifteen years ago. It would not be wrong to say that the field of instrumentation is a superset of the fast-changing fields of electronics, information technology, measurement and electronic communication. Basically, it is a multi-disciplinary stream.

Instrumentation engineering is loosely defined because the required tasks are very domain-dependent. For instance, a biomedical instrumentation expert has very different concerns from a rocket instrumentation expert, though both might have some common concerns such as selection of sensors based on various parameters.

“Instrumentation has been the fundamental engine for catalysing R&D in India. Segments like communication, aerospace and defense, industrial, computers and semiconductors, education and academia, and general-purpose electronics also use instrumentation to validate their devices, designs and deployment,” informs Jyotsna Kukreti Dobriyal, HR operations, Agilent Technologies India.

“New concepts of instrument-aware systems have opened this domain even further. Engineers at any level, whether it is design, validation or software development, need proper knowledge of test methods. This domain is growing in India,” she adds.

Hemant Kamat, chief technology officer, Shalaka Technologies, too believes that instrumentation is a very important aspect of manufacturing industry. “Instrumentation is applied in R&D, process, manufacturing and quality departments of manufacturing organisations. It is also important in building management systems—a market that is growing significantly in India,” he shares.

Scope, roles and responsibilities

Unlike services vertical, instrumentation industry is not manpower-intensive. However, it requires talented individuals that have specific skills in measurement science and engineering, believes Jyotsna. “Those who are sound in fundamentals and have specific knowledge of measurement systems will find multiple career options within this industry,” she says.

With the increasing demand for electrical power and developments in audio and video communication systems and the automation industry, electrical/instrumentation engineers have become vital to the society today.

[stextbox id=”info” caption=”Task & responsibilities of an instrumentation engineer”]- Develop concept designs and feasibility studies

– Design or update specifications and designs of electrical systems and equipment

– Design ways to generate and manage electricity

– Devise ways to control processes using automation techniques and computers

– Examine safety aspects of the planned work

– Plan manufacture or use of equipment and appliances

– Oversee testing of new systems and correction of faults

– Supervise the installation and maintenance of systems and equipment

– Design new control systems, and develop, maintain and modify existing systems

– Work collaboratively with design engineers, operation engineers, purchasers and other internal staff

– Contact clients, suppliers, contractors and relevant authorities

– Project management within cost- and time-constrained environments

– Write computer software

– Develop new business proposals

– Liaise with clients, suppliers, contractors and relevant authorities, e.g., the Nuclear Decommissioning Authority

– Understand and ensure compliance with health and safety regulations and quality standards of the country in which work is undertaken[/stextbox]

“Industries such as textile, pharmaceutical, paper, metallurgy, automotive, marine, locomotive and aerospace also require instrumentation engineers,” says Kamat.

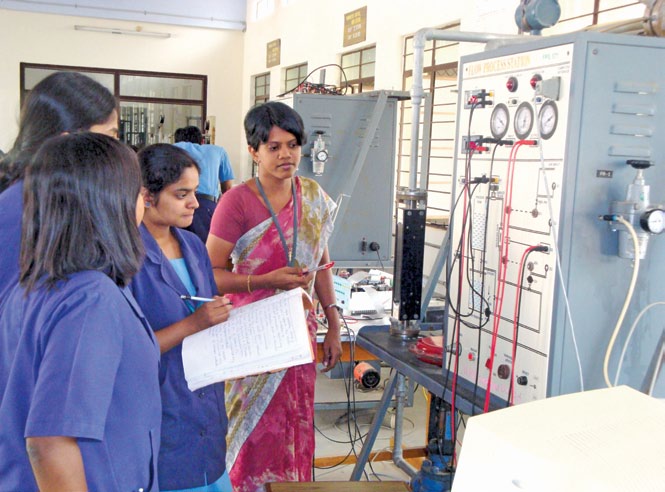

Instrumentation engineering comprises design and development of more efficient electrical machinery, control equipment and power systems for generation, transmission and distribution of electrical energy, and telecommunication. Instrumentation technicians perform operations like commissioning, installation, calibration, maintenance and repair of complex measurement and control systems used in a variety of process control operations. Those willing to make a career in this field should have a sound knowledge of measurement and control principles of pneumatic and electronic instruments theoretically as well as practically. Tasks and responsibilities of instrumentation engineers vary from company to company (please see the box).

Qualification required

A BE or B.Tech degree is desirable. However, a diploma course in instrumentation engineering after passing 10th standard will be sufficient for becoming a junior engineer. Even 10+2 passouts in science stream with physics, chemistry and mathematics as main subjects are hired. If research interests you, enroll in a Ph.D programme after completing your post-graduation. Besides basic sciences and regular engineering subjects, microwave communication, radar and television engineering, microelectronics, computers, and communication and control systems are taught at graduation level.

“Instrumentation engineers can be science graduates in physics, chemistry and geology, engineering diploma holders or graduates in electronics, instrumentation and electrical engineering. Mechanical and chemical engineers with exposure to electronics can also qualify for the job,” says Kamat.

Other areas where aspirants could look to develop their skills are intelligent controls, sensor network, speech processing, monitor control and digital signal processing to name a few.

Nature of the job

“There are many entry-level roles in the field of instrumentation engineering. Prominent among them are sales engineer, application engineer, service engineer and marketing engineer,” informs Jyotsna.

Jyotsna explains, “Sales engineers identify customer requirements and position the right product and solution from their portfolio to best align with the customer’s measurement needs. They also manage and grow customer base for the company. An application engineer has in-depth knowledge of measurement techniques and products, and is responsible for demonstrating and applying solutions, mostly on-site at the customer’s place. This enables sales and increases customers’ confidence in the company and its capabilities.”