The automotive world is moving towards a new level of personalised in-vehicle infotainment. The functionalities involved are diverse and can be broadly classified into safety, driver assistance and navigation, personalised interactive multimedia and high-performance data sharing.

These features, in turn, are powered by technological advancements such as sleek 3D-enabled displays, better navigation standards, high-end computational platforms, high-throughput wireless buses, wideband radio communication that enables on-demand high-definition (HD) audio and video on the move, and interactive touch- and gesture-enabled input devices. The best part is that these are evolving and getting better every day.

Such evolutionary car infotainment systems pose a new set of challenges at the enterprise level and the test implementation level. At the enterprise level, due to the evolution of these standards, there needs to be an integrated framework that maps the product features to the test management level. At the test engineering level, the biggest challenge faced in the verification and validation phase is the test coverage required to ensure that the systems perform under varied conditions and in various combinations as per the specifications. At the manufacturing phase, the test throughput is a key area of concern. Here is a quick overview of how test engineers are trying to overcome these challenges.

Wireless and radio standards test

There is an increasing demand for providing several radio communication standards on devices, and all within short software development cycles. To cater to this, radio frequency (RF) test engineers adopt well-defined and scalable software architectures. Fast, flexible and accurate RF hardware powered by scalable software can enable effective testing right from design and validation to production.

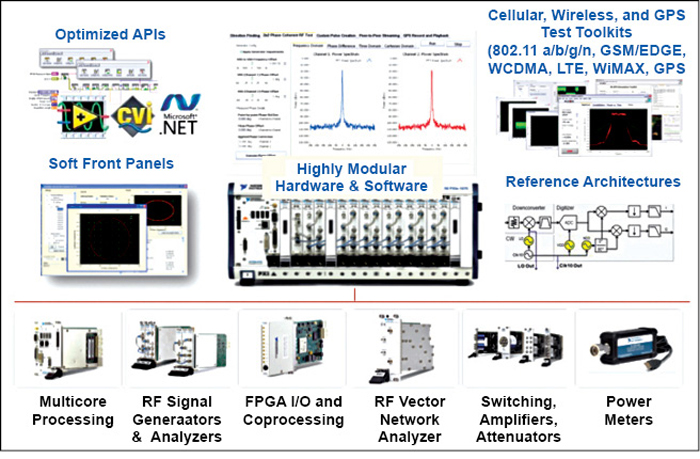

PXI is an industry-leading, PC-based platform for test, measurement and control, and is increasingly being used to test complex electronic systems in automobiles. Software-defined PXI RF test systems provide tremendous benefits for engineers running RF, microwave and wireless test applications. Using key technologies such as field-programmable gate arrays (FPGAs), multi-core CPUs and high-performance RF components, cutting-edge RF test equipment deliver commendable measurement speed, flexibility to create a wide range of applications and cost-effective measurement accuracy.

Fig. 1 shows a modular and software-defined approach to building a test system that is cost-effective, reusable and fast. Test platforms based on such an approach can test several radio standards such as AM, FM, SIRRIUS, DAB, XM, DRM and RDS; navigation standards such as GPS, GLONASS and GALELIO; and mobile communication standards like Wi-Fi 802.11a/b/g/n/ac, Bluetooth, WiMAX, EDGE, CDMA, GPRS and LTE. As these standards evolve, they can still be tested using the same platform. This reduces the system’s total cost of ownership (TCO) as the same hardware with changes in software can test multiple standards.

Audio and video test

Digital audio and video are integral parts of an automotive infotainment platform, and their quality greatly influences user satisfaction. Audio, which used to be aired from common speakers, is now becoming personalised for individual passengers, giving rise to challenges such as isolation of noise from neighbours. Measuring simply crosstalk and distortions is a thing of the past; today, people want to know the psycho-acoustical perception characteristics of the sound, and this has to be tested!

Similarly, on the video front, HD video is transferred to multiple locations, bringing in the need for a high-bandwidth wired or wireless medium. HDMI and its variants are extensively used in automobiles.

Latest test suites help in generating and testing a variety of digital audio and video standards by using a graphical system design approach. Each analyser/generator combines high-performance, PXI-based modular instruments with configuration-based software to simplify testing of multimedia devices such as set-top boxes, Blu-ray players and LCD displays. Using a single PXI system, engineers can test CVBS, S-Video, CAV, VGA and HDMI 1.4 interfaces along with audio interfaces to optimise system performance.

Other aspects to be tested

There are also sensors that enable keyless entry, voice-activated commands, and driver and passenger safety. PXI cards that can work with high-level programming software help perform multiple tests on these components.

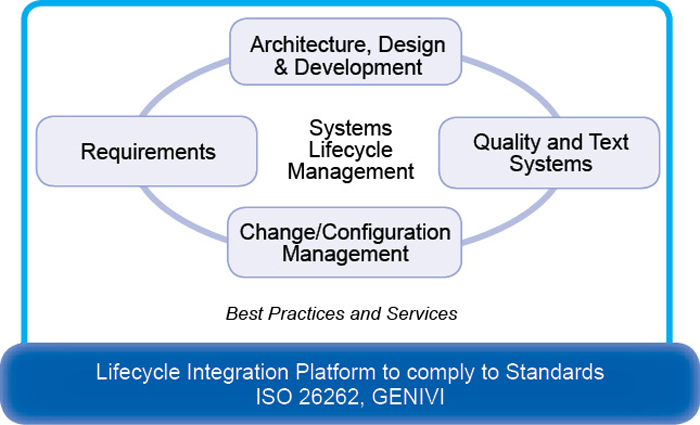

Integrating test systems with product lifecycle management

In recent years, the growing complexity of automotive products, shorter product development lifecycles and increasingly stringent compliance standards have led to the need for formalised requirements in product development and testing.