An HPL source generates a laser beam of desired power level, beam quality and time duration to be able to inflict intended damage to the enemy target. Potential candidates for building HPL sources include gas dynamic CO2 lasers, chemical lasers including hydrogen-fluoride (HF)/deuterium-fluoride (DF) and chemical oxy-iodine lasers, solid-state lasers and fibre lasers.

The ultimate quality desired of a potential HPL source is its ability to produce as high as possible a power density at the target for a given aperture size. Power density achievable for a given source-beam director combination is inversely proportional to square of wavelength and beam quality parameter for given beam director aperture size and operational range.

Therefore lower wavelength and smaller value of beam quality parameter signify its greater suitability as an HPL source. Smaller value of beam quality parameter indicates higher beam quality with unity being the ideal value. Shorter wavelength also has better target coupling efficiency.

In addition, power density at the target also depends upon atmospheric losses. Other important factors include power scalability, operator safety and ease of mounting.

Primary function of the beam-control system is to precisely point and focus laser energy at the designated point on the target and keep the same there for sufficient duration to cause intended damage to the target. In addition to target tracking and beam pointing and focusing, the beam-control system also has many other sub-systems to perform different tasks, which include beam shaping and beam stabilisation, wave-front control for atmospheric correction and so on.

In addition to laser source and beam-pointing system, propagation of an HPL beam through the atmosphere and its coupling with the target, also called target lethality, are the other important constituents determining the efficacy of a laser weapon.

The laser beam has to propagate over long atmospheric paths and the resulting propagation effects control the overall effective range or lethality range of the weapon system. Propagation effects mainly include diffraction, absorption and turbulence.

Diffraction effect tends to spread out the laser energy as the laser beam propagates, and the amount of spreading is proportional to wavelength to beam aperture diameter ratio.

This limits the smallest spot diameter to which the laser beam can be focused.

Scattering is due to atmospheric constituents and results in loss of laser energy from the beam path in other directions. Longer wavelengths have relatively lower scattering losses.

Absorption in atmospheric constituents also causes loss of energy, consequently decreasing the laser power reaching the target end. There is very strong dependence of absorption parameter on location, time of year and weather pattern.

Turbulence causes the beam to spread, resulting in an increase in laser spot size and reduction in power density at the target end. Turbulence is a strong function of altitude, wind speed and other atmospheric parameters.

Thermal blooming is another parameter that causes laser beam aberration. This arises out of heating effects produced by absorption, leading to refractive index gradient in the laser beam path. This further leads to the formation of negative lens and causes the laser beam to spread. Thermal blooming effects can be ignored for rapidly-moving targets such as airborne targets.

HPL sources

An HPL source is an important constituent of a laser based DEW system. Different types of laser sources have been exploited and experimented with for DEW application. Gas dynamic lasers and chemical lasers, HF/DF lasers in particular, were used to generate the high power levels required for a DEW application in 1970s and 1080s, as the technology of these lasers was well-established.

Due to advances in solid-state laser and fibre-laser technologies, these are considered today as the most potent laser source candidates for deployable laser weapon systems. Chemical oxy-iodine laser is also very much in contention due to its shorter wavelength of operation, particularly for generating power in megawatts.

Critical requirements

Laser power and beam quality are the two most important laser source parameters that decide the high-energy laser weapon’s lethal capability. Beam quality determines the smallest achievable focused laser spot size. This together with laser power available at the target site determines power density and, hence, lethality.

It is evident that for maximising power density at the target, one would prefer a shorter wavelength, high beam quality, larger beam director aperture size and low atmospheric transmission losses.

Shorter wavelength is preferred as it not only produces a higher power density, target coupling efficiency is also higher at shorter wavelengths. For the same laser power and transmitting telescope aperture, one-micron HPL (chemical oxy-iodine laser, solid-state lasers) would have an operational range that is approximately ten times that of a ten-micron HPL (CO2 laser) for a given power density requirement at the target.

Beam quality is essentially a measure of how tightly the laser beam can be focused to form a small and intense spot of light on a distant target. A beam quality of one signifies the laser spot size at target that is limited only by the laws of diffraction. For a real laser beam, beam quality is greater than one and hence the focused spot sizes are larger than the diffraction limited values.

Maintaining good laser beam quality as the power is scaled up is one of the most complex and challenging tasks in the laser system design. Large telescope aperture size is preferred as it produces tighter focusing and, hence, increased laser power densities at the target.

Low atmospheric transmission losses are important as the laser beam has to propagate over long atmospheric paths. For this to happen, one of the most important requirements is that the laser wavelength falls within the available transmission windows of the atmosphere in 0.4 micron to 1.7 microns (visible – NIR), three microns to five microns (MWIR) and 8 microns to 14 microns (FWIR) bands.

In addition to these requirements, another important criterion for HPL is the need to adopt power-scalable laser design architecture. The basic physics and technology of the laser system design should allow power scaling to megawatt power level needed for long-range high-energy laser weapons.

Not all laser sources, in general, meet the above requirements. Elite categories of laser sources for DEW applications are gas dynamic CO2 lasers, chemical lasers including HF/DF laser and chemical oxy-iodine laser, free-electron lasers, solid-state lasers and fibre lasers.

Gas dynamic lasers

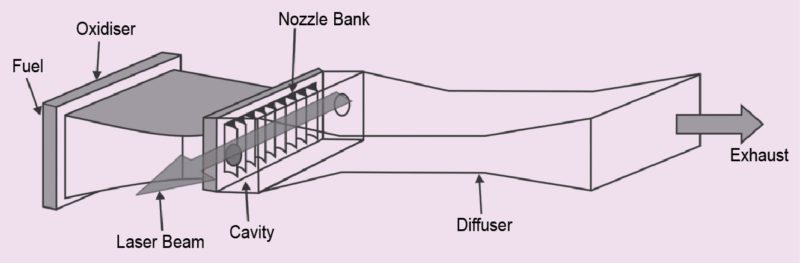

Gas dynamic lasers usually use a combustion chamber, supersonic expansion nozzle and CO2, in a mixture with nitrogen or helium, as the laser medium. Different constituents of a combustion-driven gas dynamic laser are shown in Fig. 7. The gas dynamic laser derives its energy from combustion of a suitable fuel-oxidiser mixture, which means that it does not require any electrical energy for its operation.

A gas dynamic laser achieves population inversion by rapid expansion of high-temperature high-pressure laser gas mixture produced during combustion to a near vacuum in an adiabatic process through an integrated supersonic nozzle bank. This type of laser, which is also capable of producing hundreds of kilowatts of CW power at 10.6 microns initially assumed importance as a potential HPL weapon, but it seems to have lost out in the race in favour of HF/DF and chemical oxy-iodine laser systems due to heavy absorption of 10.6 microns wavelength by water vapour in the atmosphere.

Salient features of a gas dynamic laser include long-lasing wavelength of 10.6 microns, larger beam divergence, larger telescope aperture size requirements, proven technology and non-toxic, power scale-up proven up to megawatt power level, relatively higher cavity pressure (30 torr) as compared to that of other similar HPL sources, well-established technology for direct atmospheric exhaust of lasing gases, well-suited for platform mounting. Airborne Laser Lab program of the USA launched in 1976 used gas dynamic CO2 laser as the HPL source.

Chemical lasers

A chemical laser derives the energy required to produce population inversion and consequent laser emission from a chemical reaction. Importance of chemical lasers lies in their ability to generate continuous wave output power reaching several megawatts.

Besides, the range of wavelengths generated by these lasers is well absorbed by metals, which makes these suitable for cutting and drilling operations in the industry, and more so as HPL sources for DEW applications.

There are two categories of chemical lasers. One category has HF and DF, and the other has the two iodine lasers including chemical oxy-iodine laser and all gas-phase iodine laser (AGIL). Both HF/DF and chemical oxy-iodine laser systems have demonstrated their capability to be operated at megawatt-class continuous-wave output power. Lasing action has been demonstrated in AGIL and efforts are on to scale the output to higher power levels.

Lasing wavelength of 3.8 microns in the case of DF laser has good atmospheric transmission as compared to that of HF laser emitting at 2.7 microns wavelength. HF laser is, however, better suited to Space based applications. Both have high specific energy and relatively smaller size as compared to gas dynamic lasers. DF laser of MIRACL system has demonstrated power level of 2.2 megawatts. However, HF/DF lasers produce highly toxic and explosive gases during operation and also require complex logistics.

Chemical oxy-iodine laser is a low-temperature, low-pressure device and uses non-toxic fuels. It has high specific energy and a power level of 1.2 megawatts demonstrated in Airborne Laser (ABL) programme. It operates at shorter lasing wavelength of 1.3 microns that has good atmospheric transmission. It requires a smaller aperture laser beam director and offers good target coupling efficiency. Low-pressure operation makes it better suited to airborne applications. Complex pressure recovery system is required for ground based applications.

ABL programme of the US Air Force uses a high-power chemical oxy-iodine laser system. ABL is one part of a layered ballistic missile defence system that addresses the ever-increasing ballistic missile threat. It is designed to destroy the hostile missile while it is still in the vulnerable boost phase of its flight (Fig. 8).

ABL uses an onboard surveillance system to detect and track the missile after launch. The beam-control system locks on to the target and then fires the high-energy laser. The entire system, that is, the high-energy laser, surveillance system and beam-control/fire-control system, is configured on a Boeing 747-400 fighter aircraft.

ABL made its maiden flight in July 2002. In January 2010, the high-energy laser was used in-flight, to intercept, although not destroy, a test missile in the boost phase of flight. In February 2010, the system successfully destroyed a liquid-fuel-boosting ballistic missile. In December 2011, ABL programme was reportedly shelved as it was considered to be operationally not viable.

AGIL overcomes the disadvantage of heavy, aqueous based chemistry of a chemical oxy-iodine laser device and the undesirable wavelength range of HF laser that is strongly absorbed by the atmosphere. Once scaled to higher power levels, it would be a potent laser technology for the Space-borne laser programme.

Free electron lasers

Free electron laser is a unique laser, where the process of light amplification is a bit unconventional vis-à-vis what we have seen in respect of hitherto discussed lasers. Unlike conventional lasers that rely on bound atomic or molecular states, free electron lasers use a relativistic electron beam as the active medium. In the case of a free electron laser, lasing medium is a beam of free electrons completely unattached to any atoms.

The free electron laser is tunable over a wide range of wavelengths, from X-rays to microwaves. Tunability is achieved by varying electron energy. The accelerated beam of electrons having desired energy can be obtained from well-established technology of charged particle accelerators.

Free electron lasers, though thought of as potential sources for DEW applications, have their problems when it comes to generating higher powers at shorter wavelengths. Smaller free electron lasers with power output up to 100 watts are particularly important for research and medical applications.

Solid-state lasers

Solid-state lasers are electrically-driven devices using a solid-state laser gain medium. Gain medium is pumped by either flash lamps or laser diode bar arrays, with the latter being far more widely used in the state-of-the-art solid-state lasers.

The all-solid-state configuration offers unmatched advantages in terms of compactness, robustness, reliability and logistic simplicity. However, with the present technology status, it cannot match the output laser power of megawatt level achievable in chemical lasers.

Power level of tens of kilowatts have already been realised in bulk solid-state lasers. The present technology thrust is to realise 100-kilowatt-class solid-state laser source, which would be a good enough power level for a short-range tactical directed-energy laser weapon for counter-UAV and counter-RAM applications.

Salient features of solid-state lasers of relevance to directed-energy laser weapon development include shorter wavelength, absence of chemical hazards and higher efficiency. Shorter wavelength of one-micron yields lower divergence for a given transmitting aperture size and hence longer operating ranges. Also, shorter wavelength offers better laser-matter interaction. All-solid-state electrically-operated configuration leads to a lightweight, compact and rugged system without any chemical hazards and requirement of any special support logistics. High efficiency means low operating cost and a deep magazine.

Research and development efforts in the recent years at Lawrence Livermore National Laboratory, USA, and Northrop Grumman, USA, have generated a lot of interest in high-power solid-state lasers internationally for futuristic laser based DEWs.

High-power solid-state laser programmes being pursued at the two centres follow two different design architectures. Both have the objective of developing a 100-kilowatt-class single-aperture solid-state laser. While Lawrence Livermore National Laboratory is developing heat capacity disk laser technologies, Northrop Grumman’s Joint High Power Solid State Laser (JHPSSL) programme (Fig. 9) is based on oscillator-amplifier configuration.

rtnother high-power solid-state laser based on the slab architecture previously used by Northrop Grumman to build 105-kilowatt laser is Gamma laser. The company announced Gamma in 2012 after completing an extensive series of initial tests. The laser operated at 13.3 kilowatts for a number of shots over a total of 1.5 hours with stable performance and a beam quality that exceeded design goals, completing the initial phase of trials.

Gamma laser is the basic building block that is designed in such a way that more than one such laser could be combined to produce higher power levels. The laser has also been ruggedised for survivability in real-world operational environment by subjecting key portions of the laser to vibration, shock and thermal testing.

Fibre lasers

The technology of fibre lasers is the most advanced solid-state laser technology available today. The basic fibre laser comprises a gain medium in the form of a long optical fibre of suitable material doped with lasing ions. For high-power operation, Ytterbium-doped glass fibre is typically used. The entire fibre length is pumped with a large number of single-emitter fibre coupled laser diode arrays.

The laser resonator cavity is formed by embedding Bragg grating reflectors at the two ends of the fibre. Due to the small aperture of fibre (few microns), output laser beam is emitted with diffraction-limited beam quality, resulting in output laser intensity (brightness), which is nearly two orders of magnitude higher as compared to that produced by conventional solid-state lasers.

Also, since the resonator is formed within the fibre, there is no free space optics, thereby making fibre laser extremely robust and reliable as compared to other lasers. Salient features of fibre lasers are summarised as follows:

Shorter wavelength of one micron offers lower beam divergence and therefore longer operating ranges. Shorter wavelength also has better laser-matter interaction. Fibre lasers produce diffraction-limited beam quality. These are relatively more efficient with wall-plug efficiency of about 25 per cent as compared to 10 per cent in the case of diode-pumped bulk solid-state lasers. These are also more reliable and robust due to absence of free-space optics.

The technology of fibre laser is extremely complex and confined to only couple of international companies. Single-mode fibre lasers with an output power of 400 watts – 600 watts are commercially available. The technology of kilowatt-class fibre laser is available with only a few companies including SPI Lasers UK Ltd, UK, and IPG Photonics, USA.

SPI lasers offers single-mode fibre lasers up to one kilowatt output power. At IPG Photonics, single-mode fibre lasers up to ten kilowatt power level and a beam quality characterised by M2-value better than 1.07 are well established. Multi-mode fibre lasers up to 50 kilowatt power are also available. Higher single-mode output power levels are realisable by using coherent combinations of multiple fibre laser beams.

Dr Anil Kumar Maini is former director, Laser Science and Technology Centre, a premier laser and optoelectronics research and development laboratory of Defence Research and Development Organisation of Ministry of Defence