For many actuators in automotive and industrial applications below 500W cost effective DC brush motors are still the motors of choice. On the other hand there is an ongoing transition from relay to PWM driven motors. This enables variable speed applications and more comfort plus higher energy efficiency of the drive. In addition safety, diagnosis and protection of the device are the latest needs for new designs. All these needs can be addressed with integrated bridges like the NovalithIC family, which combines a half bridge with the driver stage, diagnosis, current measurement and MOSFETs in one single package. For a fast and easy path to the next motor control design Infineon offers an Arduino power shield with the highly integrated NovalithIC driver.

There is a clear trend that the distributed loads in cars, such as HVAC blower, engine cooling fan, water and oil pumps, parking brake, front and rear wiper to name a few, driven on energy efficiency are getting smart to provide “power on demand”. In most applications, simple, low-cost DC motors are used, while dynamic DC motor control using PWM improves efficiency, comfort and safety. In a typical fuel pump application fuel savings of >1% compared to a mechanical solution can be realized. For higher power requirements the focus turns to highly efficient and durable brushless DC motors with electronic commutation.

The number of electrical motors in a vehicle increases, due to the fact that belt driven and manual functions are being replaced by electrical controlled motors. Market researchers from IHS counted 2.3 billion electrical automotive motors in 2012 and expect an increase up to 2.9 billion electrical automotive motors in 2017 with a CAGR (Component Annual Growth Rate) of 5.7%. This means an average of 30 motors per car. Today approximately 68% of these motors are DC brushed. The number of brushless DC motors is about 15%, but increasing. In industrial markets the growth rate is even higher (CAGR 6.4%). Furthermore, with billions of motors sold and high annual growth rates home appliance and consumer segments represent high potential markets. Benefits of DC motors are the simple winding and the usage of simple magnets, which enables cheap motors. But the commutator results in larger size and lower lifetime. BLDC motors are more efficient, smaller and show a longer lifetime, but are more expensive.

Integrated bridge driver

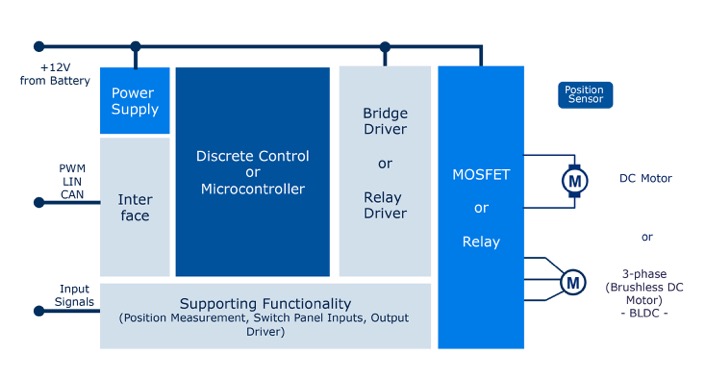

Many of the electrical drives are still controlled in a relatively simple on/off way, using relays, linear mode transistors or discrete electronics without diagnostic functions. But there is an ongoing transition to smarter and diagnosis capable motor control designs, mainly driven by improved efficiency and comfort. A typical motor control design consists of a voltage supply, communication interface, microcontroller, control stage, drivers and MOSFETs (Figure 1).

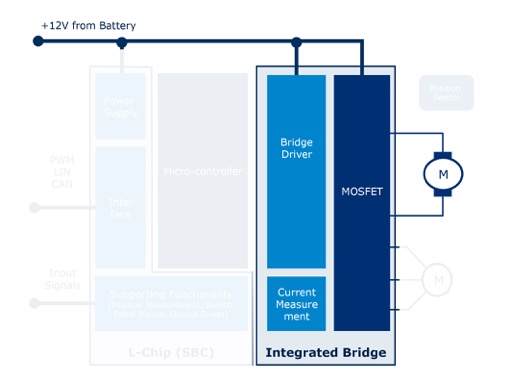

There are various integration concepts for combining functional blocks into ICs. A very efficient approach uses drives with integrated motor bridges (Figure 2).

With this solution a microcontroller permits digital control and advanced diagnostic functions. Monolithic H-bridges or multichip-ICs (Half and/or H-bridges) with integral protection features are used on the load side, which simplifies the development required for controlling the motor. A variety of small unipolar and bipolar drives benefits from this integrated protection concept at the driver side.

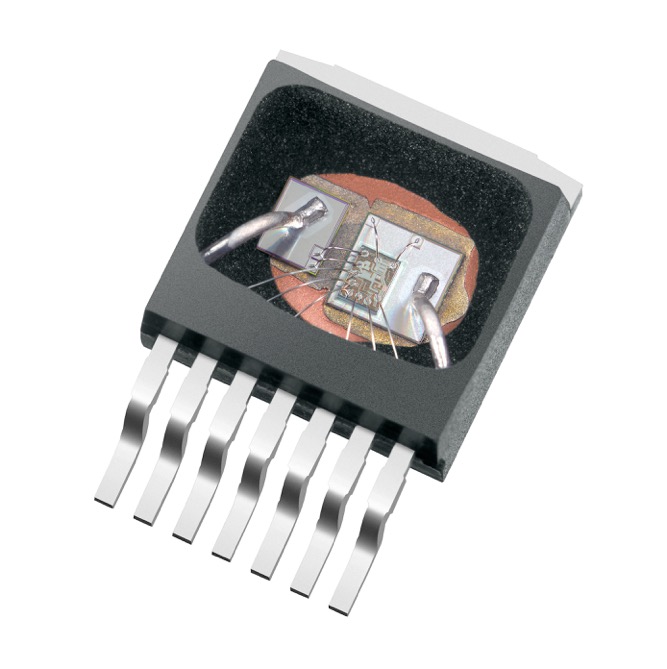

The block diagram (figure 3) illustrates a complete low-ohmic-protected half-bridge in a single package. It can be used for unidirectional motor control and – through the combination of two devices – as an H-bridge (bidirectional motor control) as well. The outlined NovalithIC device from Infineon has the capability to switch with a high frequency PWM while providing current limitation functionality, undervoltage and overtemperature protection. This concept offers cost-optimized solutions for protected high-current PWM motor drives with very low board-space consumption and provides the following advantages:

Very low parasitic inductances between high side and low side MOSFET

Optimized switching performance of the MOSFETs to reduce power losses and EMC emission

Drive the motor with PWM for torque and speed control

Active freewheeling

Integrated current measurement

Integrated diagnosis and protection

Microcontroller-compatible input pins

Small and PCB-area saving package