JUNE 2009: The need for test and measurement (T&M) is across industries. Whether in automotive or manufacturing plants, engineers and scientists need flexible, cost-effective solutions for test, control and design to ensure quality, safety and the most advanced products.

T&M devices are required during the lifecycle of any product, beginning from the design phase to the development phase and later in the production phase. For example, while designing a receiver module, a signal generator is used to provide the necessary signals in order to stimulate a response from the receiver. A spectrum analyser is often used in this setup as the reference receiver, and the results from the test receiver and spectrum analyser are compared. Using these results the design of the test receiver is constantly modified.

One major challenge faced by test engineers is to stay ahead of the technology curve. That is, in order to test the product it is imperative for them to have extensive knowledge of the subject. Given the transient nature of technology, it becomes a real challenge for the test engineers to keep abreast with the new developments and address these applications in an ever-expanding domain.

Major applications in this digital age

Radical advances in digital technology are forging a globally networked society, bringing huge changes to the electronics industry. Computers, consumer electronics and mobile devices are merging into one always-connected, networked realm, changing the way we communicate, work, play and travel by reshaping our relationship with the world around us.

There are five major application areas in the new digital age for T&M devices: digital RF, high-speed serial data, digital video technologies, embedded system technologies and next-generation network.

Challenges before engineers

The digital-age applications pose many challenges to test engineers. One major challenge is to make the underlying complexity of the next-generation technologies appear simple. This can be achieved through improved functionality, ease of use, greater performance and seamless interoperability.

Digital RF challenge. Digital RF introduces new problems, including runt pulses and broadband transients that cannot be seen with conventional tools. The time spent troubleshooting these problems has a direct impact on the products’ time to market. These problems are often DSP-related, and may not be easily repeatable. If the problem only occurs once a day, being able to capture the state of the device-under-test (DUT) the first time it happens can literally take days to find the root cause.

Engineers need to find spurious signals across a broad frequency range, and these signals are getting smaller and moving faster than ever before. Once the signals are found, they need to get to root cause as soon as possible. To do this, it is necessary to pinpoint the problem in the DUT. Being able to correlate data taken at the time of a failure at multiple points in the design, in multiple domains, is essential to providing rapid insight.

[stextbox id=”info” caption=”Types of T&M devices”]

Broadly, the T&M products can be classified into products for general-purpose test and measurement; video test, measurement and monitoring; and communication diagnostics and network management.

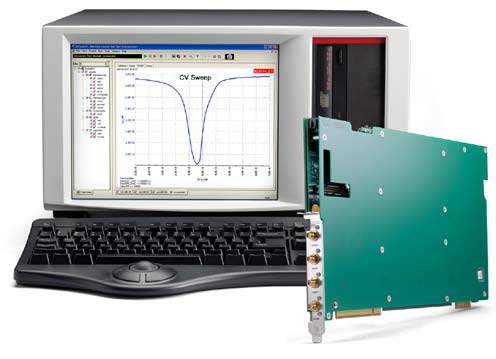

The general-purpose test products include oscilloscopes, logic analysers, signal sources and spectrum analysers. Oscilloscopes are the primary general-purpose electronic debug tools. Logic analysers are debug tools used by design engineers to capture, display and analyse streams of digital data that occur simultaneously over many channels. Signal sources are general-purpose stimulus products primarily used in the design and manufacturing of electronic components, sub-assemblies and end products in a wide variety of industries. Spectrum analysers are primarily used in the design and manufacture of electronic components, sub-assemblies and end products that utilise digital RF technology.

Video measurement equipment are used to ensure delivery of the best possible video experience to the viewer, either through traditional analogue television, or through digital terrestrial, satellite, cable or broadband services. These include waveform monitors, video signal generators and compressed digital video test products. They are used in video equipment design and manufacturing, video content production, and video transmission and distribution.

Similarly, network management and diagnostic tools enable network equipment manufacturers and operators to develop, deploy, and manage mobile and fixed-line networks. Network management tools provide continuous performance management to optimise the service performance of an entire communications network. Diagnostic tools test and monitor the signaling protocols in next-generation communication networks and services.

[/stextbox]

Finally, their budget hasn’t changed. They can buy a spectrum analyser/VSA combination device, or an RTSA, but not both. All the functions of a high-performance spectrum analyser and vector signal analyser must be included in their troubleshooting and characterisation tool.

Embedded system design challenge. Today, we see a vast array of complex electronic circuits, or embedded system designs, in a wide range of applications—from low-cost to high-performance. The design engineers creating these embedded systems are faced with many of the same design challenges.