Inserting a metal fluoride layer in multi-layered perovskite-silicon can enable charge separation and enhance performance.

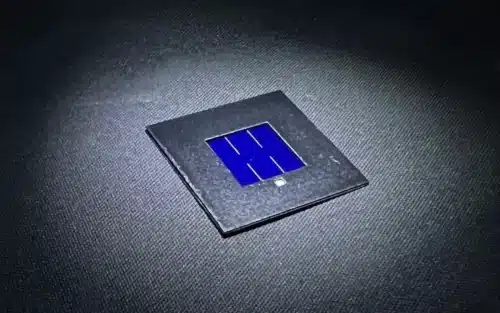

Perovskites have a unique crystallographic structure that makes them highly effective at converting photons of light from the sun into usable electricity. Tandem solar cells combine perovskite and silicon based sub-cell devices to better capture and convert sunlight into electrical energy compared to the traditional conventional single junction silicon cells.

When sunlight strikes the perovskite surface the resulting electrons and holes tend to recombine at the interface between the perovskite and electron-transport layer. A mismatch between energy levels at this interface hinders electron separation within the cell resulting in reduction of the tandem cells’ open-circuit voltage, or maximum operating voltage, which restricts device performance.

Researchers tried various metal fluorides as interlayer materials at the perovskite/C60 interface of tandem cells. They then thermally evaporated metal fluorides on the perovskite layer into an ultrathin uniform film with controlled thickness before adding C60 and top contact components. The magnesium fluoride interlayer effectively promoted electron extraction from the perovskite active layer while displacing C60 from the perovskite surface. This enhanced the charge transport and reduced the charge recombination at the interface.

According to lead author Jiang Liu, a postdoc in Stefaan De Wolf’s group, the resulting tandem solar cell achieved a 50 millivolt increase in its open-current voltage and a certified stabilized power conversion efficiency of 29.3 percent — one of the highest efficiencies for perovskite–silicon tandem cells.

“Considering that the best efficiency is 26.7 percent for mainstream crystalline silicon-based single-junction cells, this innovative technology could bring considerable performance gains without adding to the cost of fabrication,” he added.

To further develop the technology and its applications, the research team is developing scalable methods to produce industrial-scale perovskite–silicon tandem cells with areas exceeding 200 square centimeters (31 square inches). “We are also developing several strategies to obtain highly stable tandem devices that will pass the critical industrial stability protocols,” Liu says.

REFERENCE : DOI: 10.1126/science.abn8910