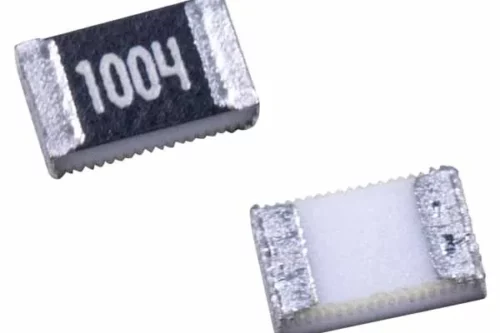

This high power density component can conserve printed circuit board (PCB) area and improve reliability by reducing temperature rise factor.

As people’s need rise, the technology advances. And though the technology advances, yet the base on which it is being developed barely changes. The processor may change its features but it is always built using the properties of silicon. No matter how sophisticated technology one uses, thermodynamics always kicks in. The devices at a point will dissipate energy in the form of heat. This cannot be avoided but it can be limited.

The reduction of heating up of a device is necessary to conserve the device and improve its reliability. The TFHP series thin film high power chip resistors are developed for precision power supplies, power amplifiers, and process control applications, which all benefit from carefully designed element-to-terminal increased heat transfer.

“The unique values offered by these resistors allow designers to reduce component size, minimise temperature rise, and increase reliability in high-power analog circuit designs,” said Nick Atkinson, Senior Product Line Manager, TT Electronics.

The new TFHP series offers 2W in the 1206 chip size and 6W in the 2512 chip size. Additionally, the TFHP features large area terminations for improved thermal contact with the PCB. These high power resistors offer better accuracy than thick film alternatives. They offer 0.1% tolerance, 25ppm/°C TCR, reduce self-heating and improve linearity.

“Aluminium nitride based TFHP with the precision of thin film technology is a strategic addition to TT’s growing portfolio of power chip resistors,” said Nick. The TFHP product family combines high power and high precision in a single resistor, capitalising on aluminium nitride (AIN) ceramic substrate with nearly six times the conductivity of alumina, the conventional substrate material for chip resistors.