Researchers at the Indian Institute of Science (IISc) Have invented pressure sensors using cellulose papers that can achieve high sensitivity requirements

Pressure sensors have a wide range of applications in industries and healthcare applications as they need accurate and precise pressure measurement. As flexible and wearable sensors are manufactured using petroleum-based polymers which are non-biodegradable plastics, their large-scale production can cause great harm to the environment. Hence, researchers have fabricated pressure sensors that use paper as the medium. The disadvantage of using a paper-based pressure sensor is its lack of sensitivity.

“In any sensor, there is always a trade-off between sensitivity and dynamic range. We want to have high sensitivity. Sensitivity is essentially a measure of the smallest entity (amount of pressure) that we can detect. And we want to sense that quantity over an extensive range,” says Navakanta Bhat, Professor at the Centre for Nano Science and Engineering (CeNSE) and corresponding author of the paper published in the ACS Sustainable Chemistry & Engineering. His team has proposed a design for the paper sensor that, by its structure and multilayering, achieves high sensitivity and can detect a broad range of pressures (0-120 kPa) with a response time of 1 millisecond.

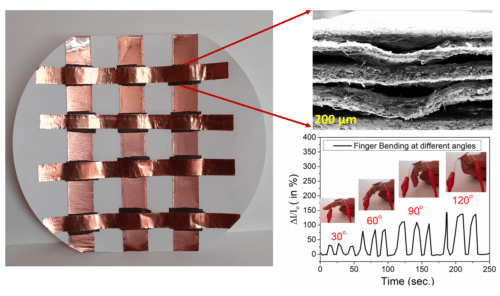

The process of using these paper pressure sensors is when pressure is applied on the sensor’s surface, the air gaps between the paper layers decrease, increasing the contact area between these layers. With the increase in contact area leads to better electrical conductivity. On releasing the pressure, the air gaps increase again, thus decreasing the electrical conduction. This modulation of the electrical conductivity drives the sensing mechanism of the paper sensor.

The sensor is made of plain and corrugated cellulose papers coated with tin-monosulfide (SnS) stacked alternatively to form a multi-layered architecture. SnS is a semiconductor that conducts electricity under specific conditions. “Paper in itself is an insulator. The major challenge was choosing an appropriate 3D device structure and material to give conductive properties to paper,” says Neha Sakhuja, a former Ph.D. student at CeNSE and the first author of the paper.

“Our key contribution is the simplicity of the device. It is like creating paper origami,” explains Bhat. “The future applications of this device are limited only by our imagination,” says Bhat. “We would [also] like to work on increasing the stability and durability of these sensors and possibly collaborate with industries to manufacture them in large numbers.”

Click here for the Published Research Paper