Today’s industry players are accelerating the speed of automotive technology innovation as they develop new concepts of electric, connected, autonomous, and shared mobility. Major automotive megatrends for electrification and digitalization involve zone architectures, digital driving of power devices, battery management systems, power electronics and power / energy management. The growing demand for more power and safety in Electronic Control Units (ECUs) is driving system designers to develop smart power distribution solutions.

Already in traditional ICE solutions, the new power distribution concept is well established and smart subsystems have already been introduced for reliable and efficient solutions. This strongly affects the concept of power distribution in ECUs, implying the replacement of traditional fuses with solid-state protections. They save systems in case of extra stress due to ultra-high current spikes, but also prevent malfunctions and mishandling. The system can be restarted once the risk is overcome, without replacing any electronic block or fuse.

ST released the new STPOWER STripFET F8 40V series, which perfectly meets the stringent requirements for electronic fuse (eFuse) solutions in terms of high ruggedness against linear mode operation and energy management.

Power Distribution in Automotive Systems

The major trend in power distribution systems is the replacement of the centralized architecture, which distributes the electric power from the battery to the individual loading systems and includes a central relay and fuse box for overload protection. The new automotive systems are based on smart power distribution with multiple small power distribution centers in a decentralized architecture. These small centers communicate each other with a local interconnect network (LIN) or controller area network (CAN). The modular implementation allows a zonal architecture in the vehicle, which strongly reduces the wire harness, thus optimizing system cost and weight in addition to the electrical performance.

The smart modules, operating as electronic fuses (eFuses), guarantee huge benefits for the enhanced diagnostic and protection associated to the real time information exchange. In addition, the solid-state switches minimize the losses of the power distribution system, thus improving the fuel efficiency of the vehicle and decreasing carbon dioxide emissions. Finally, eFuses increase the system reliability, fulfilling the stringent automotive safety requirements.

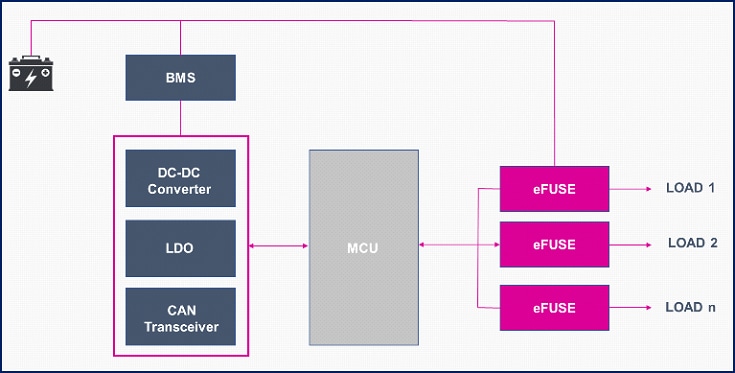

The block diagram of an automotive smart power distribution system is shown in Fig. 1.

The eFuse smart switch integrates a control circuit driven by a micro controller unit and a power switch. For high-power automotive systems, where a high current limitation is requested, an external power switch is used, consisting of high rugged and low on-resistance power MOSFETs.

Selection Criteria for Power Switches

The guidelines for the choice of the external power switches are ruggedness in linear mode when switched-on and ruggedness against avalanche when switched-off. These features play a key role for the optimization of high-current power distribution systems.

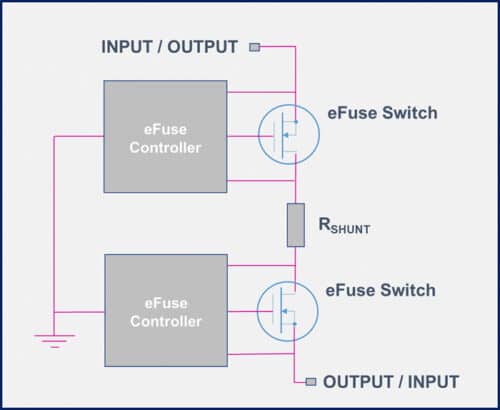

A comprehensive analysis is described for the eFuse smart switch in an electric power steering (EPS) system. The maximum total current reaches 160A with a cycle time of about 40 seconds and 10 seconds of pause for a sequence of 6 times, then four power MOSFETs connected in parallel are considered with a double back-to-back configuration to ensure a bidirectional protection from battery to load and vice versa (Fig. 2):

The shunt resistor (Rshunt) is inserted to detect in real time the current flowing in the branch, then turn off and shutdown the system in case of an accidental increase in current. It also helps to keep the current constant by transferring the feedback signal to the controller which tunes the gate-source voltage (VGS) of the MOSFET accordingly to limit the current to the target value.

-

Ruggedness in Linear Mode

The power distribution system has to provide at turn on a constant current for the soft charging of the ECU bulk capacitors, thus limiting the inrush current and preventing any voltage spikes. This condition determines a linear mode operation for the power switch.

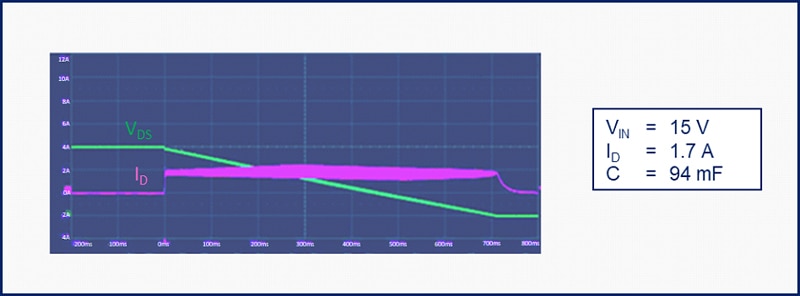

The STL325N4LF8AG was tested with a dedicated benchmark and measured waveforms are reported in Fig. 3:

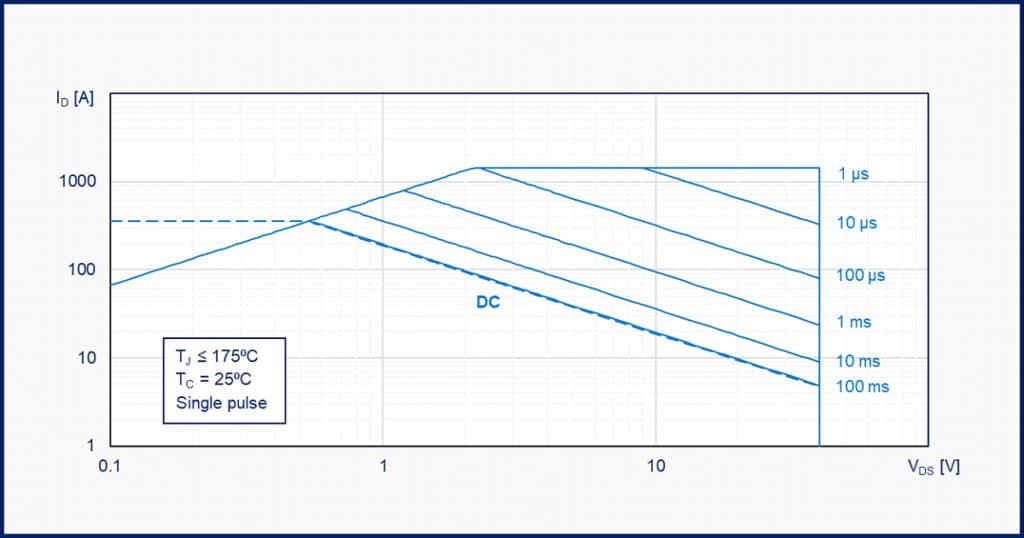

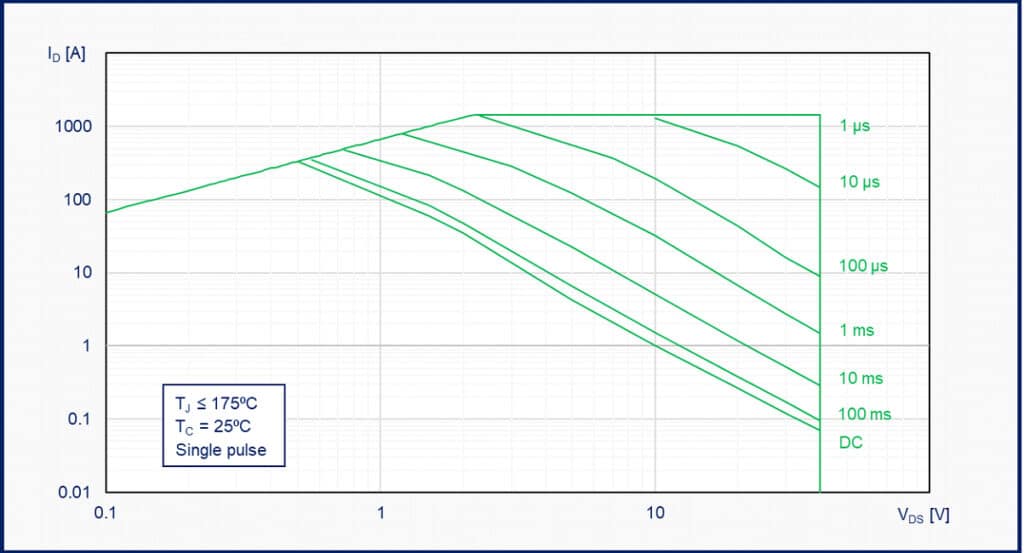

At the above conditions, the MOSFET is able to withstand the linear mode working conditions with a significant charging time of 700ms. Therefore, the safe operating area (SOA) has to be checked to verify the condition can be guaranteed as safe and reliable for the device. The theoretical SOA curves for STL325N4LF8AG are shown in Fig. 4:

However, thermal instability produces quite a severe de-rating on the MOSFET performance, by significantly lowering the current handling capability. This phenomenon is known as Spirito effect and is caused by the uneven distribution of current across the silicon die. Below the zero thermal coefficient (ZTC) point, if a small region is at a higher temperature than the rest of the die, it will draw more current and dissipate more power becoming even hotter. This process eventually leads to thermal runaway and the destruction of the MOSFET as a three-terminal short. Burn marks will appear near the center of the die and close to the die bonding structure.

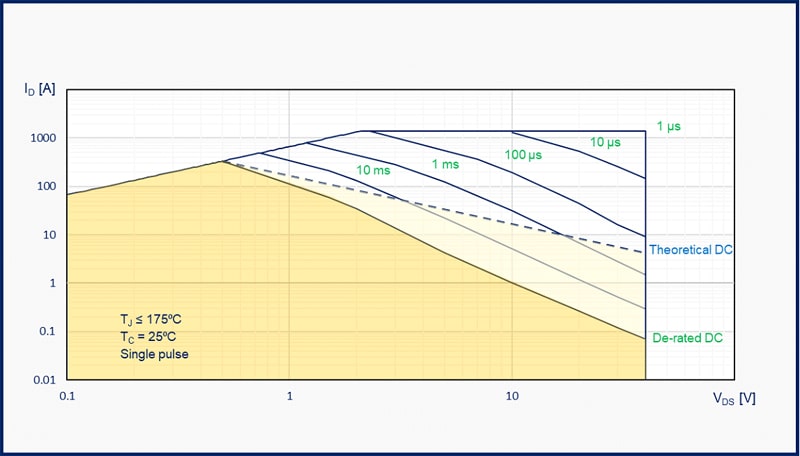

Moreover, these hotspots are observed to occur more frequently at wider power pulses. For a time pulse of 10ms, the Spirito effect takes place at a lower VDS (about 2V) than for the 1ms pulse (about 4V), while DC operation is limited by thermal instability at any voltage, as shown in Fig. 5:

A close comparison between the theoretical SOA curve at steady state condition (as worst case) and the relevant de-rated curve with the Spirito effect is shown in Fig. 6:

By including the Spirito effect, for a VDS of 10V, the maximum current the STL325N4LF8AG can handle under DC operation drastically goes from theoretical 19A down to 1A.

The linear mode working condition relevant to the pre-charging phase of the bulk capacitor of the ECU can be reported on the de-rated DC curve of the SOA, by assuming 700ms equivalent to a steady state condition. The mean value of the power managed by the MOSFET can be calculated as below reported (Eq. 1):

PD = ID x VDS_(mean) = 1.7 x (15 : 2) = 1.7 x 7.5 = 12.75 W (1)

where: PD is the power dissipated during the pre-charging phase;

ID the constant drain current of the MOSFET;

VDS_(mean) the mean value of the drain voltage of the MOSFET during the charging time.

The linear mode point is in a safe region of the SOA, therefore the STL325N4LF8AG exhibits the ruggedness mandatory for avoiding the thermal runaway.

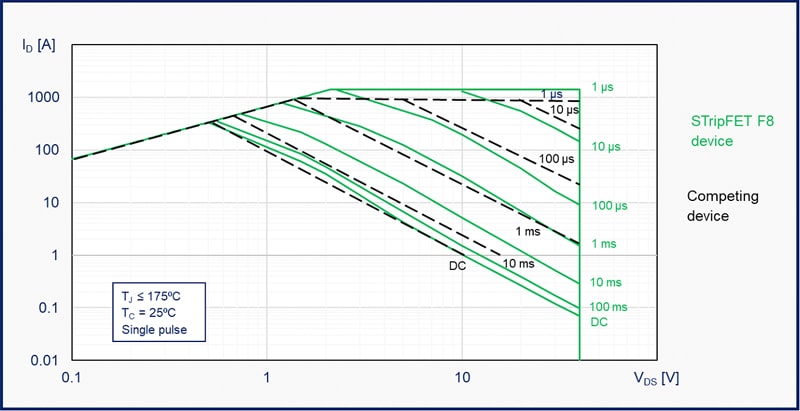

A comprehensive comparison of the SOA curves of an equivalent AEC Q101 MOSFET (same breakdown voltage and on-resistance in an equivalent package) from one of the main competitors is shown in Fig. 7:

The STripFET F8 MOSFET exhibits wider SOA regions for pulse times starting from 1ms, showing higher margin especially at 10ms.

Comparing the DC curves at 7.5V, the following values can be obtained:

- ID = 1.9A for ST’s F8 MOSFET;

- ID = 1.8A for competitor’s MOSFET.

Hence, the STripFET F8 MOSFET exhibits good steady-state performance with high ruggedness in linear mode operation perfectly aligned with the competition.

Ruggedness against Avalanche

At turn off the current lasts for several microseconds, which deposits considerable energy into the eFuse and the power switches.

In fact, the wire harness that connects the main battery to the final application control board results in a high impedance associated to the parasitic stray inductance. This produces a sustained voltage spike which leads the MOSFET to the avalanche region.

The eFuse failure mode at turn off is then associated to the breakdown of the drain−source junction of the MOSFET.

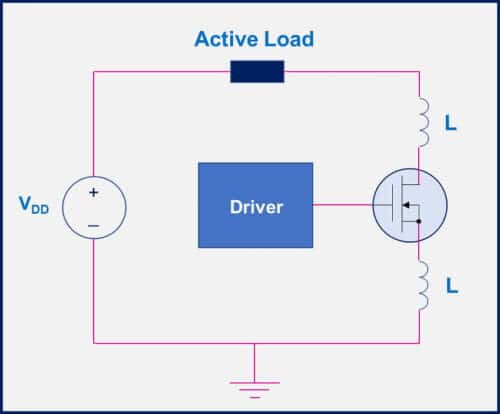

For the EPS system, a parasitic inductance of 7µH can roughly be considered at both drain and source connection, then the following testing circuit can be considered (Fig. 8):

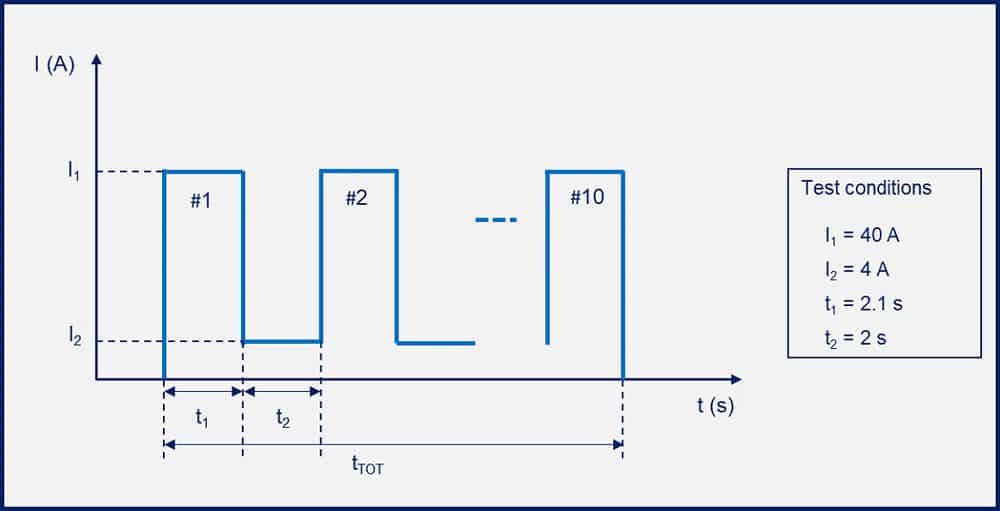

The test was performed at the following conditions related to the single power switch current profile, shown in Fig. 9:

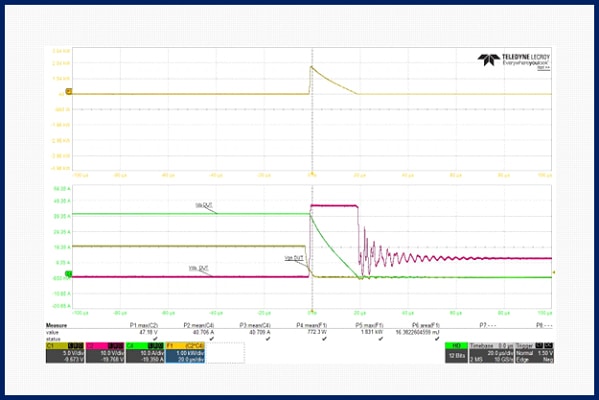

At turn off, the MOSFET enters the avalanche mode, by reaching a maximum value of the drain-source voltage of 47.2V which exceeds the breakdown voltage. In this condition, the device has to manage a single pulse avalanche energy (EAS) of 16.8mJ for an avalanche time (tAV) of 20µs, as shown in Fig. 10:

The avalanche condition is reliable and safe for the MOSFET if the operating temperature remains lower than the absolute maximum rating value (equal to 175⁰C).

In this case, the EAS energy for tAV = 20µs determines a power dissipation (PD) given by (Eq. 2):

PD = = 840 W (2)

From the datasheet, the thermal impedance value relevant to tAV = 20µs is the following (Eq. 3):

Zth = K (@ 20µs) x RthJC = 0.023 x 0.8 = 0.018 ⁰C/W (3)

Then, the temperature variation (DT) is given by (Eq. 4):

DT = PD x Zth = 15 ⁰C (4)

and, with an initial junction temperature (TJ_in ) of 25⁰C, the operating temperature (TJ_oper) in avalanche condition becomes (Eq. 5):

TJ_oper TJ_oper = TJ_in + DT = 25 + 15 = 40 pC (5)

This ensures the STL325N4LF8AG device can safely manage the discharge energy in the eFuse system.

A comprehensive comparison of the guaranteed EAS values of an equivalent AEC Q101 MOSFETs from the main competitors is reported in Tab. 1:

| IAV [A] |

EAS [mJ</sub] |

ΔEAS (ST vs Comp) [%] |

|

| ST | 30 60 |

1170 590 |

— |

| Competitor 1 | 29 | 706 | + 66 |

| Competitor 2 | 30 60 |

800 400 |

+46 +47 |

Tab. 1. Avalanche energy comparison with competing devices.

Then, the innovation introduced with new trench structures to ST’s STripFET F8 technology deeply increases the performance not only in switching, but also in avalanche conditions, making the MOSFET operate in safe and reliable mode.

Conclusions

Experimental data demonstrate the STL325N4LF8AG can withstand the stressful conditions associated with eFuse applications. Best-in-class behavior makes the STripFET F8 MOSFET the ideal choice for safe and reliable power distribution systems in harsh high current automotive applications.