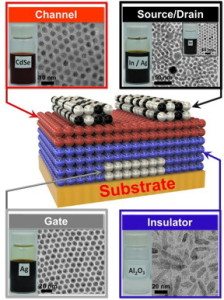

Transistor fabrication is a highly complex process, requiring high-temperature, high-vacuum equipment. In another step in combining consumer electronics and nanotechnology, University of Pennsylvania engineers have shown a new approach for making transistors: sequentially depositing their components in the form of liquid nano-crystal inks. The researchers’ nano-crystal-based field effect transistors were patterned onto flexible plastic backings using spin coating but could eventually be constructed by additive manufacturing systems, like 3-D printers. The study lead by Cherie Kagan, the Stephen J. Angello Professor in the School of Engineering and Applied Science, and Ji-Hyuk Choi, then a member of her lab, now a senior researcher at the Korea Institute of Geoscience and Mineral Resources, explains the materials as colloids like the “ink in your inkjet printer”.

Image credits: University of Pennsylvania

“These materials are colloids just like the ink in your inkjet printer,” Kagan said, “but you can get all the characteristics that you want and expect from the analogous bulk materials, such as whether they’re conductors, semiconductors or insulators.”

“This is the first work,” Choi said, “showing that all the components, the metallic, insulating, and semiconducting layers of the transistors, and even the doping of the semiconductor could be made from nano-crystals.”

With this new method of making transistors, nanotechnology could take a more active role in equipment manufacturing.

Such a process requires mixing the components in precise patterns. “The trick with working with solution-based materials is making sure that, when you add the second layer, it doesn’t wash off the first, and so on,” Kagan said. “We had to treat the surfaces of the nano-crystals, both when they’re first in solution and after they’re deposited, to make sure they have the right electrical properties and that they stick together in the configuration we want.”

“Making transistors over larger areas and at lower temperatures have been goals for an emerging class of technologies, when people think of the Internet of things, large area flexible electronics and wearable devices,” Kagan said. “We haven’t developed all of the necessary aspects so they could be printed yet, but because these materials are all solution-based, it demonstrates the promise of this materials class and sets the stage for additive manufacturing.”

The detailed story can be found at: http://www.nanotech-now.com/news.cgi?story_id=53301