Researchers at the University of Groningen have produced an organic solar cell with a record efficiency exceeding 17%, the maximum for this type of material.

Organic solar cells are made from polymers and small molecules. The cells are very thin, flexible, and easy to make. However, these cells’ efficiency is much less than the conventional silicon-based ones.

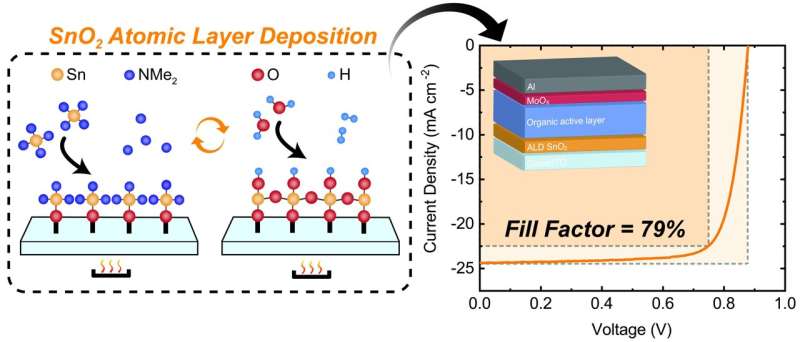

Researchers at the University of Groningen have fabricated an organic solar cell with a very high efficiency of over 17%, which is the maximum for this type of material. The design consists of a conductive layer of tin oxide grown by atomic layer deposition. Polymers and molecules convert light to charges in organic solar cells. The cells are thin films with distinct layers stacked on a substrate. The crucial layers are the photoactive layer, which transforms light into charges and separates electrons and holes, and the transport and blocking layer, which guides electrons to the electrode.

Stability

Zinc oxide is often used as the electron transport layer in organic solar cells, but tin oxide may offer more device stability. The researchers tested the concept of using tin oxide instead, and tin oxide is less photoreactive than zinc oxide. The tin oxide was potentially a transport layer for organic solar cells, but the growth process was unclear. The team used atomic layer deposition, an infrequently used technique in photovoltaics, with superior layer quality and industrial scalability.

Scalable

The organic solar cells made with atomic layer deposition of tin oxide perform well. The team of researchers reports a 17.26% efficiency in solar cells. The tin oxide layer’s optical and structural features can be tailored by adjusting the deposition temperature. The maximum power conversion was achieved at 140 degrees Celsius for two different active layers, implying generic efficiency improvements. The researchers sought to enhance the efficiency of scalable organic solar cells. The cell’s efficiency is near the current record of 19%, with room for further optimization. The authors plan to produce larger area cells, which are less efficient but necessary for real-world applications.

The team of researchers believe that the solar cell’s high fill factor is a good basis for future study, but industrial partnerships need to be revised. They also expect their atomic layer deposition technique to inspire others. The tin oxide transport layer is a promising first step, though there’s room for improvement.

Reference : Lorenzo Di Mario et al, Outstanding Fill Factor in Inverted Organic Solar Cells with SnO2 by Atomic Layer Deposition, Advanced Materials (2023). DOI: 10.1002/adma.202301404