A team of technologists from multiple nations has achieved a noteworthy advancement in the development of flexible monocrystalline silicon solar cells.

Solar cells have been used in numerous clean energy applications for over fifty years, generating electricity. However, the majority of these cells have been flat and inflexible, limiting their range of usability. The scientific community, application developers, and end users have long anticipated the advent of flexible solar panels that match the efficiency and durability of their rigid counterparts.

A multinational team of technologists, comprising researchers from various institutions in China, Germany Saudi Arabia, have achieved a significant breakthrough in creating flexible monocrystalline silicon solar cells.

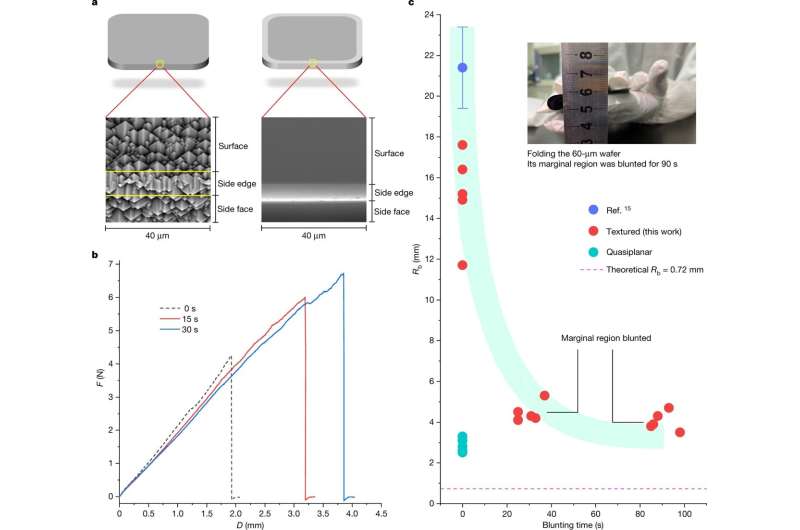

The team initiated their efforts by conducting simulations to explore the viability of various ideas. During this process, they devised two distinct methodologies for enhancing the semiconductor materials utilized in solar panel production. The first approach involved a wet chemical process, while the second approach employed a dry, plasma-based technique.

During real-world testing, the team successfully demonstrated that the two techniques could be utilized to produce thin, flexible panels. However, both methods encountered a common issue of excessive reflectivity. Through microscopic analysis, it was discovered that microscopic cracks emerged between pyramid-shaped bumps formed on the panel’s surface during processing. The team subsequently discovered a solution by devising a method to soften the bumps and channels that developed along the edges, where cracks tended to appear. Subsequent testing revealed that cracks still occurred, but the panel remained intact without breaking, thereby enabling the cell to bend and remain functional.

The flexible cells’ devices exhibited comparable efficiency and durability to their rigid counterparts. Moreover, the research team discovered that the cells could be readily manufactured on a large scale. Additionally, due to their significantly lighter weight compared to conventional solar cells, they opened up many new applications.

Reference :

Wenzhu Liu et al, Flexible solar cells based on foldable silicon wafers with blunted edges, Nature (2023). DOI: 10.1038/s41586-023-05921-z

Flexible solar cells made with crystalline silicon, Nature (2023). DOI: 10.1038/d41586-023-01357-7