The reference design for three-wheeler BMS epitomizes the next generation of electric vehicle technology with enhanced performance, safety, and versatility.

A Data-Acquisition System with Integrated Current Sense Amplifier is a pivotal component in Three-Wheeler Battery Management Systems (BMS). Tailored for electric three-wheelers, this sophisticated tool ensures optimal performance, longevity, and safety of the battery pack. In the rapidly evolving electric vehicle industry, especially in the segment of three-wheelers, having a specialized BMS caters to the unique needs of this vehicle type. This system not only aids in managing moderate voltage levels efficiently but also monitors and maintains battery health, promoting efficient energy use and safeguarding the vehicle’s core power source.

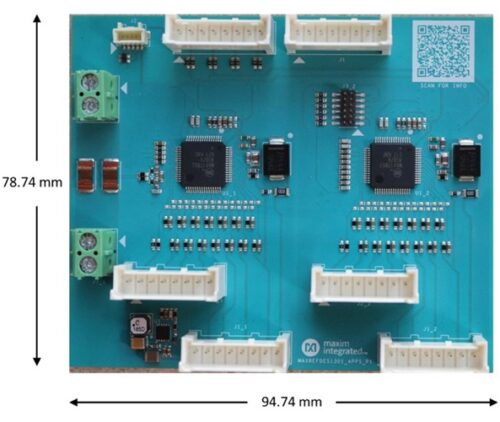

The MAXREFDES1301 reference design from Analog Devices offers an immediate evaluation platform for the MAX17852 and MAX17853, specifically designed for 96V three-wheeler BMS. The design exemplifies the effectiveness of the 14-channel High-Voltage Data-Acquisition System when interconnected in a daisy chain. This configuration allows for measurements of two sets of 14-cell voltages, total pack voltage, pack current, and temperature and facilitates passive cell balancing. Furthermore, the MAX17852 and MAX17853 adhere to the Automotive Safety Integrity Level-D (ASIL-D) criteria, addressing cell voltage, temperature, current, communication, and Failure Mode Effects Analysis (FMEA) standards.

The design has various sophisticated features to enhance its performance and versatility. Capable of measuring voltages for a range between 6 to 28 cells, it ensures an accuracy of ±2mV within a temperature bracket of 5°C to 40°C. The design supports a flexible pack configuration and uses an external current sense resistor to measure the battery pack’s current. One of its standout features is the passive cell balancing of up to 300mA, facilitated by an internal switch that operates on an odd or even cell balancing scheme. This scheme can be tailored to accommodate either a single cell or an ensemble of cells, and users can choose between automatic balancing based on under-voltage thresholds and timer parameters or a manual configuration.

Further enhancing its capabilities, the design offers configurable auxiliary inputs. While the MAX17853 is primed with six channels for temperature measurements, the MAX17852 features four channels structured for I2C and GPIO. An internal die temperature measurement mechanism ensures consistent performance. Safety remains paramount, with the system providing configurable alerts for overvoltage, undervoltage, overtemperature, and under-temperature faults, as well as cell mismatch signals. Communication options are versatile, allowing users to select between a universal asynchronous receiver transmitter (UART) or a serial peripheral interface (SPI). The UART configurations, equipped with packet error checking, come in dual and single versions.

Analog Devices have tested this reference design. It comes with a Bill of Materials (BOM), schematics, Printed circuit board (PCB) layout, etc. You can find additional data about the reference design on the company’s website. To read more about this reference design, click here.