The package enables the use of SiC for mid-power applications from 250kW.

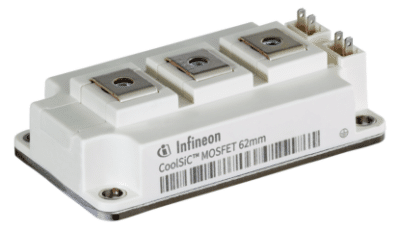

Infineon Technologies has expanded its CoolSIC 1200V and 2000V MOSFET module families with the introduction of a 62mm industry-standard package. The device, featuring a half-bridge topology, is built on the advanced M1H silicon carbide (SiC) MOSFET technology.

The M1H technology enables a broader gate voltage window, which enhances robustness against voltage spikes at the gate caused by driver and layout influences. This improvement is particularly beneficial at high switching frequencies, and it enables the use of SiC in mid-power applications starting from 250kW.

This range is especially relevant where traditional silicon with insulated-gate bipolar transistor (IGBT) technology falls short in terms of power density. With this new technology, the scope of applications now extends beyond those of a standard 62 mm IGBT module. The expanded range includes sectors such as solar energy, servers, energy storage, electric vehicle chargers, traction, commercial induction cooking, and various power conversion systems.

The module has minimal switching and transmission losses, reducing the need for extensive cooling systems. Combined with high reverse voltage capabilities, these devices are expected to align with the requirements of modern system design. CoolSiC chip technology aids these converters to be more efficient, allowing for increased nominal power per inverter and reduced system costs.

The device packaging is designed for durability, featuring a baseplate and screw connections optimized for maximum system availability, minimal service costs, and reduced downtime losses. It has high thermal cycling capacity and a continuous operation temperature of 150°C.

The symmetrical internal design of the package ensures identical switching conditions for both the upper and lower switches. There is an option to enhance thermal performance by applying a pre-applied thermal interface material (TIM).