The recently developed eco-friendly electrochemical refrigerant compressor achieves isothermal compression of environmentally friendly refrigerants efficiently and silently by harnessing electrochemical reactions.

In alignment with the Korean government’s recent initiatives aimed at achieving carbon neutrality by 2050, there has been a notable acceleration in the shift from fossil fuels to new and sustainable energy sources. A collaborative research team headed by Principal Researcher Young Kim from the Korea Institute of Machinery and Materials (KIMM), an institution overseen by the Ministry of Science and ICT, along with Professors Min-sung Kim and Dong-kyu Kim of Chung-Ang University, have successfully developed an environmentally-friendly refrigerant compressor by employing an electrochemical approach in lieu of a traditional mechanical method.

Unlike traditional refrigerants containing HFCs (hydrofluorocarbons), which harm the ozone layer and contribute to global warming, environmentally friendly refrigerants such as ammonia and R1234yf have minimal environmental repercussions. Following the guidelines set forth in the Kigali Amendment to the Montreal Protocol, developed nations in Europe, the United States, and Japan are actively transitioning to eco-friendly refrigerants, with the goal of entirely phasing out HFC usage by 2024. The adoption of environmentally friendly refrigerants not only aids in averting environmental pollution but also plays a pivotal role in promoting sustainable development.

Electrochemical Compressors: Silent, Durable, and Efficient Solutions

Mechanical compressors face several constraints, including issues with the durability of components due to rapid rotation, refrigerant contamination caused by lubricants, and noisy operation. In contrast, electrochemical compressors, devoid of moving parts and lubricant dependencies, offer a solution to address the drawbacks associated with traditional mechanical compressors. Furthermore, electrochemical compressors can maintain a consistent flow rate at different pressure ratios and boast high efficiency, which can substantially enhance the Coefficient of Performance (COP) of heat pumps.

In order to optimize the energy-saving benefits of the rooftop greenhouse, the research team has designed an “optimized smart farm operating solution” capable of managing all aspects of the system, including air conditioning, LED lighting, and the hydroponics system, in response to external weather conditions. The team intends to showcase this solution through a practical demonstration within the rooftop greenhouse.

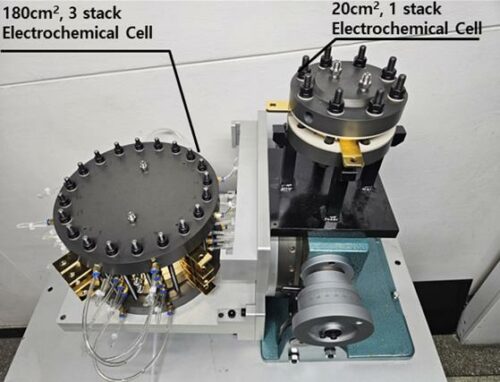

The collaborative research team has acquired the essential core technologies required for manufacturing an environmentally-friendly electrochemical refrigerant compressor and for designing the associated system. They have also effectively conducted a test run.

The Electrochemical Advantage

In contrast to conventional mechanical compression, an electrochemical compressor achieves refrigerant compression by mobilizing ions through the application of DC (direct current) voltage to the ion exchange membrane, utilizing hydrogen as the carrier gas. Additionally, it offers the capability for isothermal compression by implementing a multi-layer freezing technique, where cells are stacked together. Up to this point, the research team has successfully compressed refrigerants such as ammonia, a natural refrigerant, and R1234yf, an environmentally friendly refrigerant. The collaborative research team has engineered cells that exhibit robust performance even under repeated high-pressure conditions and has demonstrated a leak-proof design to prevent refrigerant leakage at elevated pressures. Furthermore, by designing a channel capable of delivering high performance even at high voltage, the team has achieved maximum compression efficiency with the electrochemical compressor.

The electrochemical compressor possesses the remarkable ability to deliver the desired compression ratio, irrespective of its size. It can maintain a stable flow rate that aligns with the compression ratio and boasts exceptional efficiency. Consequently, it finds utility not only in the construction of high-efficiency plants and heat pumps but also in the development of smaller-scale systems. Of particular note, an electrochemical ammonia compressor can effectively handle the compression of ammonia, even when ammonia serves as a carrier gas for hydrogen. This versatility makes it a valuable tool for establishing hydrogen infrastructure as well. This research received backing from the project focused on the “development of a chemical absorption-type heat pump employing an electrochemical compressor,” under the guidance of the Korea Institute of Energy Technology Evaluation and Planning within the Ministry of Trade, Industry, and Energy.