MIT researchers have created eco-friendly batteries for electric cars, matching cobalt-based batteries in cost-effectiveness with the potential for lithium replacement.

Numerous electric vehicles rely on batteries containing cobalt, a metal associated with significant financial, environmental, and social burdens.

MIT researchers have created a sustainable battery material for electric cars using an organic cathode instead of cobalt or nickel. It matches cobalt-based batteries in conductivity and capacity and charges faster at a lower cost.

Alternatives to cobalt

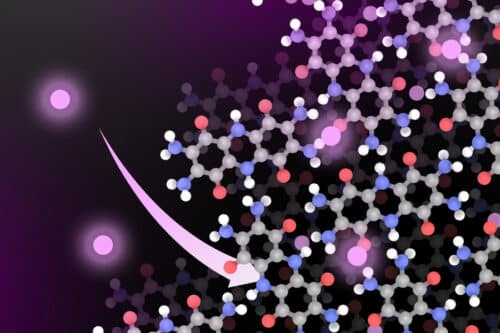

The team aims to develop an organic battery suitable for powering electric vehicles. While exploring porous materials combining organic and inorganic elements, they unexpectedly discovered a fully organic material with promising conductivity characteristics. This substance comprises numerous layers of TAQ (bis-tetraaminobenzoquinone), an organic molecule featuring three fused hexagonal rings, which can extend in multiple directions, resembling a graphite-like structure. Within these molecules, quinones act as electron reservoirs, while amines facilitate the formation of robust hydrogen bonds. These hydrogen bonds contribute to the material’s high stability and remarkable insolubility, a crucial trait preventing it from dissolving into the battery’s electrolyte, thus extending its lifespan, unlike other organic battery materials.

Strong performance

Tests of this material have demonstrated that its conductivity and storage capacity are on par with conventional cobalt-based batteries, and batteries featuring a TAQ cathode exhibit faster charging and discharging rates, potentially accelerating the charging process for electric vehicles. Researchers introduced filler materials like cellulose and rubber to enhance the stability and adhesion of the organic material to the battery’s copper or aluminium current collector.

These fillers constitute less than a tenth of the overall cathode composite, thus having negligible impacts on the battery’s storage capacity. Additionally, these fillers extend the cathode’s lifespan by preventing it from cracking as lithium ions flow in during charging. The key components required for manufacturing such cathodes—quinone and amine precursors—are readily available as commercial products produced in substantial quantities as commodity chemicals. Researchers estimate that the material cost of assembling these organic batteries could be roughly one-third to one-half the cost of cobalt batteries.

The researchers aim to explore replacing lithium with more affordable and abundant sodium or magnesium in future battery materials.