Continuous selective soldering enhances efficiency in electronics manufacturing by boosting throughput and flexibility, while simultaneously minimizing space requirements and ownership costs.

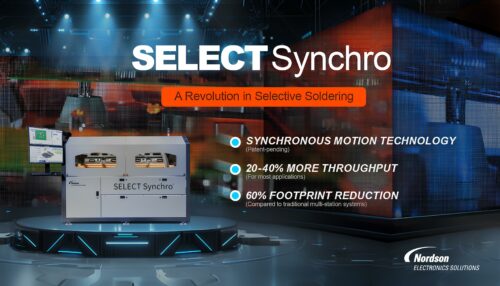

Nordson Electronics Solutions introduces the Synchro 3, the latest addition to its Synchro series of selective soldering equipment. The SELECT Synchro series, including the Synchro 3, Synchro 5, and Synchro 5 XL, employs innovative synchronous motion technology, significantly reducing conveyance time. The Synchro 3 offers up to three solder pots, accommodating different alloys and nozzle configurations to meet diverse manufacturing needs. Designed for high-volume printed circuit board (PCB) assembly, the Synchro 3 aims to enhance solder joint quality and ensure product reliability in electronics manufacturing.

The key features include:

- Reduces equipment footprint by up to 60%

- Increases throughput by 20-40% for most applications

The Synchro 3 and 5 models can handle PCBs up to 2500 x 460 mm, while the Synchro 5 XL is capable of managing boards up to 2500 x 680 mm. All systems in the Synchro series come equipped with a range of advanced features, including automatic conveyor-width adjustment, a drop-jet fluxer, a flux-level sensing system, a titanium solder pot and pump assembly, a quick-change magnetically coupled solder nozzle, pre-heaters, a warpage sensor, a system camera, and access to process data for traceability.

The SELECT Synchro systems are designed to efficiently solder a wide range of board assemblies, from single-sided to double-sided through-hole, mixed-technology surface mount, and through-hole, without interruption. These systems automatically balance soldering tasks between pots, further increasing throughput. They come standard with process control features, easy point-and-click programming, and fiducial finding capabilities, making them versatile tools that can adapt to your specific manufacturing needs.

Florian Strohmayer, Product Line Manager at Nordson Electronics Solutions, expressed the company’s commitment to expanding the Synchro product family in response to positive industry feedback. The Synchro 5 XL was introduced to accommodate wider boards, and now the Synchro 3 provides a broader range of solutions for selective soldering processes. Nordson continues to collaborate with customers looking to replace wave soldering equipment or upgrade their existing selective soldering operations.