Strike while the iron is hot! The global digital TV (DTV) market is red hot iron for original equipment manufacturers (OEMs) with about 300 million units expected to be sold by 2015. Even more radiant is the high-end DTV business commanding 20 per cent of the DTV market today.

The perfect digital TV today must provide connectivity, best-in-class video and graphics, seamless user experience, advanced features of auto-stereoscopic 3D or multi-/free-viewpoint TV, integration with social networks and wireless audio-visual stream, and a smart TV ecosystem. Innovation in the display technology and custom processing logic—traditionally the forte of OEMs—alone can’t create magic.

There is a need for new silicon platforms with multiple derivatives every 18 months, and in-depth understanding of complexities at the chip and software level to get the differentiating complex DTV system-on-chip (SoC) mould out faster. Simultaneously, there is mounting pressure on OEMs to become cost-effective with every product for different market segments.

Changing DTV landscape

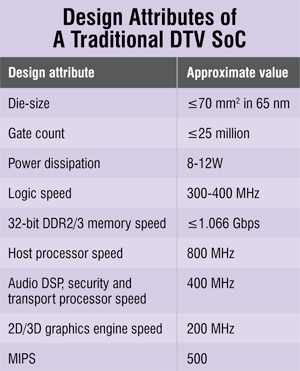

Today’s DTV doesn’t comprise the olden-day chips where everything was done through a dedicated analogue circuitry with minimal central processing unit (CPU) processing and some digital audio/video acceleration. DTV SoCs have moved away from traditional DTV SoCs that had a single-core processor with a low-power graphics engine and capacity to handle 500 MIPS.

Block diagram of next-generation media SoC

Today, the complexity of the next-generation DTV media SoC has grown manifold. OEMs are looking at integrating most features into the DTV media SoC. This is resulting in design complexity shifting from the board design to the DTV media SoC.

The DTV media SoC has become the heart of DTV, just like an application processor powering a mobile phone. Alongside, more software is being encapsulated in the silicon today, making the chip behave more like a platform executing software along with serious hardware acceleration and post-processing assists. Software differentiation in this dynamic DTV landscape is fast becoming essential to preserve product differentiation. This calls for a need to scale the hardware accordingly.

These rising challenges are driving OEMs towards a next-generation complex DTV media SoC that would comprise a dual- or quad-core (ARM Cortex A-15) application processor, high-end graphics with multiple 3D and 2D cores, high-performance SoC configuration to support data throughput of 60 f/s x 2 = 120 f/s for auto-stereoscopy, dedicated hardware blocks for video post-processing (like for scaling, filtering and enhancement), multi-format HD decoders and encoders supporting new functionality, multi-view coding or distributed video coding, support for next-generation inputs like HDMI and LVDS ++, and standard and legacy interfaces. DTV OEMs would typically want to take advantage of advanced nodes like 28nm/22nm technology to achieve power and cost efficiencies during the realisation of next-generation DTV media SoC.

Handling next-generation complex DTV SoC design complexities and managing time-to-market and cost pressures today pose a huge challenge for OEMs. Optimisation of system-modeling, verification, prototyping, emulation and silicon validation cycles of the SoC development can help DTV OEMs reduce time to market. A unified domain-aware modeling-verification-emulation-validation approach holds such a strong promise.

Unique domain-aware modeling-to-validation approach

Unified domain-aware modeling-to-validation approach involves reducing the overall SoC verification and validation cycle time by focusing on reuse and domain-based frameworks during phases of system modeling, verification, rapid prototyping, emulation and silicon validation.

A DTV SoC typically contains significant processing, hardware-software co-design and dedicated hardware interface blocks. A standard verification environment will not help validate many end-use cases, resulting in a need to move into emulation, SoC architecture modeling and top-level register-transfer level (RTL), and conducting independent verification, validation and emulation of the SoC. However, there are commonalities at each stage.

To arrive at a time- and cost-efficient product development model, one needs to unify these commonalities and build reusable domain-based frameworks. For example, take the scenario of an emulation box where high-level languages cannot be used. Creating a test bench for any stage—verification, validation or prototyping—without the knowledge of the emulation environment requirements would result in rework at the emulation stage. Hence, just like the way OEMs use DTV IP frameworks to arrive at an optimal design, reusable and unified verification approach is one of the key levers to shorten the specification-to-production timeline for the DTV-media chip and thus achieve faster time to market.

Keeping pace with next-generation technologies

From the application software standpoint, OEMs need to adopt next-generation technologies like green TV and personal home assist, integrate new-age operating systems like Android and Google TV, handle integration issues of middleware stacks of emerging and existing standards, and integrate/manage the complete smart TV ecosystem for content. Ensuring the integration of DTV SoC with next-generation technologies is a challenge for DTV OEMs. Let us analyse the challenge posed by next-generation green TV and personal home assist technologies.

Green TV. Today, upgrades and eWaste are seen as a pressing issue in the DTV landscape. On an average, a consumer in the US or Japan is willing to consider buying a new DTV every four years. With technology changing at the speed of light, the customer might soon find his DTV outdated. This is driving the demand for a future-proof and truly green TV.