The technique allows for creating structures with different substances and porousness levels, with applications ranging from porous medical implants to lightweight aerospace products.

University of Florida engineers have introduced a 3D printing technique known as vapor-induced phase-separation 3D printing (VIPS-3DP), enabling the creation of both single-material and multi-material objects. This innovation holds significant promise for advancing additive manufacturing. Professor Yong Huang, Ph.D., from UF’s mechanical and aerospace engineering department, highlighted the economic and sustainable benefits of this printing process. He emphasized its simplicity and affordability, particularly for printing advanced materials such as metals, as reported in Nature Communications.

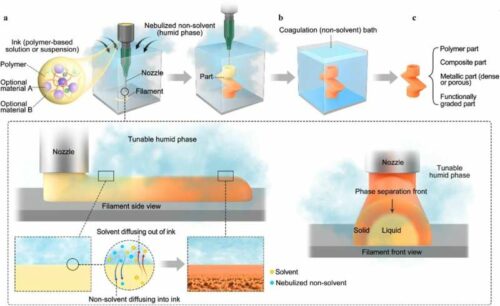

The technique utilizes special eco-friendly liquids as “ink” for the printer, consisting of dissolvable polymer-based liquids with embedded metal or ceramic particles. During printing, a non-solvent vapor is released, solidifying the liquid part of the ink and leaving behind the solid material—a process known as vapor-induced phase separation. This method enables the creation of multi-material parts with spatially tunable, multi-scale porosity, allowing for structures with different substances and porousness levels at various locations.

Adjusting printing conditions or sacrificial material usage during the process can control the object’s porousnesThe team noted the potential of VIPS-3DP for creating metallic products with varying porousness levels, citing bone tissue engineering as an example where implants need to integrate with human cells.

Apart from its economic benefits and ability to create intricate structures, it is also environmentally friendly. It requires less infrastructure investment and uses sustainable materials, contributing to a greener approach compared to traditional printing methods. This development represents a significant step forward in the field of additive manufacturing, offering new possibilities for cost-effective and sustainable production of advanced materials.