This reference design provides an efficient, lightweight, and cost-effective alternative to traditional automotive door control switch panels, paving the way for advanced automotive control applications through wireless communication.

Automotive door control switches are vital in modern vehicles, enhancing convenience and safety. They manage functions like locking/unlocking doors, controlling windows, and adjusting mirrors, centralizing control to improve efficiency and reduce driver distraction. Advanced switches feature integrated safety mechanisms such as child locks and emergency egress functionalities, crucial in emergencies. They also support smart technologies, enabling keyless entry/exit and enhancing security. Beyond personal vehicles, these switches are used in commercial and public transportation, ensuring passenger safety and comfort. As vehicle technology evolves, their integration with systems like central locking, anti-theft alarms, and automatic window controls highlights their essential role in the automotive industry.

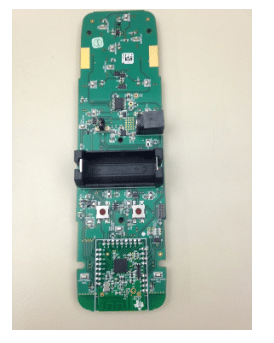

This automotive door control switch reference design presents a proof-of-concept solution for a door control switch panel that communicates wirelessly with door-side mirrors, window lifts, and door lock mechanisms. By utilising Texas Instruments (TI) automotive-qualified Bluetooth low energy + MCU CC2541-Q1 system-on-chip (SoC) solution, this design offers significant cost, weight, and fuel savings by replacing the traditionally expensive and heavy cable harnesses with a wireless alternative.

The design TIDA-00356 by Texas Instruments demonstrates the use of Bluetooth low energy for automotive control applications, showcasing the replacement of wires and harnesses with a robust and mature Bluetooth ultra-low power SoC solution that has full Bluetooth low energy certification. It includes dual-power input, featuring a coin cell battery mode for fully independent, portable operation, and supports a wide input voltage range from 3V to 50V LDO for direct car battery operation, with integrated reverse battery protection. The design is capable of operating effectively in start-stop and cold-start environments and features an AEC-Q100-qualified device. The automotive-qualified CC2541-Q1 is available with a slight pinout change from the CC2541.

The design employs the SAT0016 BLE module, which includes crystals and a PCB antenna, greatly simplifying layout and design considerations. Primary layout considerations for the main board include minimizing the distance to power capacitors to ensure stable operation and avoiding any excess metal or ground planes in close proximity to the module antenna to maintain optimal signal strength and performance. All PWM channels are tied together to a single GPIO. The LED driver, which is not operational off the Li-Ion battery, has current in each channel limited to 20mA via the reference resistor R11. Special layout considerations should be observed to ensure proper thermal dissipation when running the LED driver at this limited current for extended periods. TPD devices require minimal configuration and can protect the CC2541 from Level 4 Contact Discharge on each of the tactile switches.

TI has tested this reference design. It comes with a bill of materials (BOM), schematics, assembly drawing, printed circuit board (PCB) layout, etc. You can find additional data about the reference design on the company’s website. To read more about this reference design, click here.