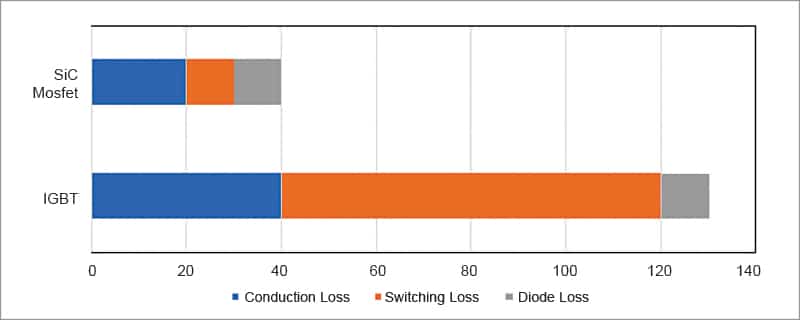

Silicon carbide (SiC) revolutionises power semiconductors, cutting switching losses by

up to 90% and enhancing efficiency and compactness. As demand for electric mobility

and sustainable energy grows, SiC drives a greener, more efficient future.

With its enhanced efficiency and durability, SiC is not just a material; it’s the cornerstone of sustainable technological progress. It improves the overall performance of electronic components, positioning itself as a critical element in the future of high-power applications.

A webinar hosted by Diotec and IBS Electronics highlighted SiC’s advantages over traditional silicon in applications like EV chargers and solar inverters.

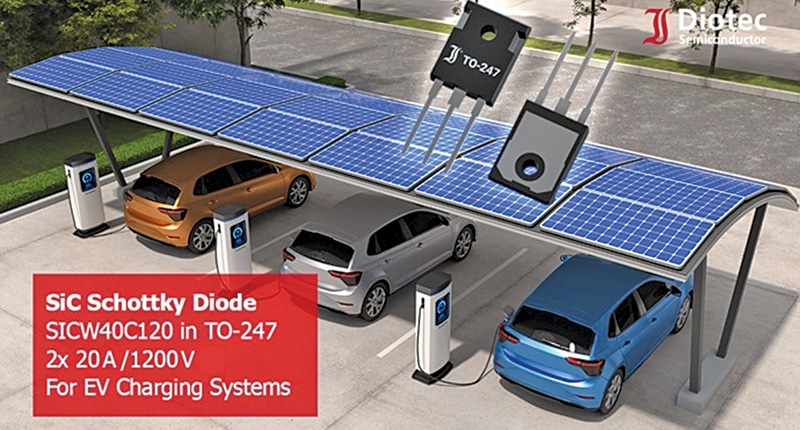

SiC technology is revolutionising various sectors with its capabilities in high voltage and high frequency switching applications, which are essential for electric vehicle charging and solar inverters. Discussions on the latest SiC MOSFETs and Schottky diodes demonstrated their significant impact on efficiency and performance, making SiC a pivotal element in the future of power electronics.

Silicon carbide is more expensive than traditional silicon, yet for many manufacturers, its benefits far outweigh the cost. With an electrical breakdown field of 2.8 x 106V/cm, SiC exhibits a ten times higher tolerance than silicon’s 3.0 x 105V/cm, enabling higher withstand voltages and efficiencies due to its low ‘on’ resistance. The bandgap energy of SiC is 3.26eV, three times higher than silicon’s 1.12eV, which supports higher operating temperatures and boosts reliability. Additionally, SiC’s electron drift velocity of 2.2 x 107cm/s is double that of silicon, facilitating faster switching, which can lead to size reductions and higher operating frequencies in devices. Moreover, SiC’s thermal conductivity is 4.9W/cmK, three times that of silicon, leading to a lower temperature rise and superior thermal management in applications.

One might wonder if wide bandgap (WBG) materials like SiC and GaN are at a disadvantage compared to silicon, being closer to insulators than conductors. However, their wide bandgap allows for much thinner dice for the same voltage rating, reducing on-resistance and lowering thermal resistance. Additionally, WBG materials start with lower leakage currents that rise more slowly with temperature increases. These materials can also tolerate higher operating temperatures, enhancing their power handling capability for a given device size despite the limitations of their die attached solder or packaging.

| What makes Silicon Carbide (SiC) a Game-Changer |

| The rising affordability of EVs is underscored by the lower charging costs at public stations, typically ranging from ₹22.20 to ₹31.07 per kWh—significantly cheaper than the expenses associated with diesel-powered vehicles. Over the lifecycle of an EV, this price difference translates into considerable savings. But how substantial is the environmental impact? According to the Association of German Engineers (VDI), a medium-sized EV becomes environmentally beneficial after 90,000km, boasting emissions about 55% lower than traditional combustion engines over a span of 200,000km. Amidst these developments, SiC is revolutionising power semiconductor technology. Components by various companies highlight SiC’s superior performance, showcasing up to 90% lower switching losses compared to silicon alternatives. But why does this matter? This efficiency permits higher switching frequencies, drastically reducing the size of components such as coils and transformers, thus enhancing the compactness and efficiency of the systems. With the growing demand for electric mobility and sustainable energy solutions, SiC’s contribution to enhancing the efficiency and performance of high-voltage power systems becomes more vital. Its robustness in handling the rigorous demands of modern energy needs cements its position as a pivotal material in steering us towards a greener, more efficient future. |

Enhanced charging technology with SiC

As these silicon-based semiconductors take the stage, they are set not only to meet current industry needs but also to anticipate future demands, making them pivotal in the evolution of technology across various industries. In a remarkable advancement for electric vehicle technology, the focus has shifted towards enhancing the efficiency and capacity of onboard chargers, heralding a new era of high-performance electric mobility. SiC-based power devices are leading this transformation, offering a suite of benefits that propel the capabilities of electric vehicles (EVs) forward.

With EVs consuming between 11kWh and 30kWh per 100 kilometre—often estimated at 15kWh for typical usage—the surge in electricity demand is undeniable. This growing appetite for power necessitates not only robust energy systems but also innovative solutions like solar carports. These installations, which can be found at corporate parking lots, supermarkets, and residential buildings, not only provide power but also protect vehicles from environmental elements. Additionally, their integration with bidirectional charging systems supports energy storage and grid balancing, enhancing the sustainability of EV ecosystems.

As the EV market continues to expand, the demand for more efficient and faster charging solutions becomes critical. Silicon carbide technology is at the forefront of meeting these needs, offering higher efficiency and reduced power loss compared to traditional silicon-based devices. This shift is not merely incremental; it is pivotal in enhancing the overall performance of electric vehicles. Silicon carbide-based devices provide substantial improvements over their silicon counterparts:

Higher efficiency

SiC devices operate with significantly higher efficiency. This capability leads to lower power loss during conventional procedures, which translates into better overall vehicle performance.

Improved thermal management

Due to its superior thermal conductivity, silicon carbide can handle higher temperatures and improve the reliability and efficiency of chargers.

Greater power density

The ability of SiC to operate at higher temperatures also allows for higher power density within chargers. This means that chargers can be more compact and lightweight, aligning with the current trend toward minimising the size and weight of electronic components in vehicles.

Enhanced switching frequency

SiC devices can switch on and off at much higher frequencies than silicon devices, minimising energy loss during switching. This feature is critical for optimising the efficiency of the energy conversion process in EVs.

Higher operating voltages

Capable of withstanding higher voltages, SiC devices enable the design of more flexible and robust electrical systems within vehicles.

SiC MOSFET: A sustainable future

A specific example of this innovative technology in action is the use of SiC MOSFETs in EV onboard chargers. These devices demonstrate significantly reduced conduction and switching losses, enhancing power efficiency and reducing heat generation during operation. The Kelvin source pin, a feature of some SiC devices, optimises switching behaviour further by minimising the parasitic inductance usually found in traditional setups.

The adoption of silicon carbide technology in electric vehicles is a game-changer for the automotive industry. It not only improves the performance and efficiency of the vehicles but also contributes to the broader goal of reducing carbon emissions. As EVs continue to grow in popularity, innovations like SiC are critical in making sustainable transportation a practical reality for more people around the world.

The integration of silicon carbide into electric vehicle technology represents a significant leap forward in our journey towards an electrified, efficient, and environment friendly transportation system. As this technology continues to evolve and scale, it promises to unlock new possibilities for the automotive industry, driving us towards a more sustainable future. Silicon carbide is not just an alternative; it is becoming the standard for the next generation of electric vehicles.

Amid the surging demand for electric vehicles, the need for efficient and robust onboard chargers has become a top priority. Silicon carbide technology is becoming a cornerstone in this development, thanks to its superior properties compared to traditional silicon in power applications. This shift promises to significantly boost the performance and efficiency of electric vehicle chargers, a key component in the EV infrastructure.

Automotive qualifications

A key highlight in the utilisation of SiC technology is its compliance with the rigorous AEC-Q101 standard, which is critical for automotive applications. This certification ensures that SiC devices can perform under the demanding conditions typical in automotive environments, particularly in power factor correction (PFC) circuits used in EV chargers.

The move towards silicon carbide is not just about enhancing current technologies but is also a step towards futureproofing the automotive industry. As EVs continue to evolve, the requirements for more efficient, reliable, and compact power solutions grow. Silicon carbide stands out as a material that can meet these needs today and tomorrow.

By adopting SiC in their products, companies are not only addressing the immediate needs of the automotive sector but are also setting new standards for the performance of electronic components in EVs. This collaboration is poised to drive significant advancements in the industry, reducing carbon footprints and enhancing the sustainability of vehicle technologies. This development not only enhances the efficiency and performance of electric vehicles but also aligns with global efforts to promote sustainable transportation. As silicon carbide technology continues to mature, its role in the automotive industry is set to become more pivotal, promising a cleaner, more efficient future for all.

SiC: Reliability, efficiency, and manufacturing excellence

As the electric vehicle (EV) industry evolves, manufacturers continue to seek out innovative solutions that enhance performance, reliability, and lifespan. Silicon carbide, a robust semiconductor material, is emerging as a key player in this transformation, offering significant advantages over traditional silicon in high-power applications.

Silicon carbide stands out for its high thermal conductivity and ability to operate at lower temperatures, which significantly enhances its reliability. This makes SiC an ideal choice for demanding environments, particularly in the automotive industry, where high quality and reliability are paramount. Vehicles equipped with SiC-based devices can enjoy longer lifespans and reduced maintenance costs, making SiC a preferred material for EV applications.

The production process of silicon carbide devices is distinct and more refined compared to traditional silicon, which helps in achieving higher quality and performance. Manufacturers have optimised production lines specifically for SiC, enhancing the overall quality of the final product. This attention to detail in manufacturing ensures that SiC devices are not only more efficient but also more reliable over their operational lifespan.

When selecting the optimal packaging for power devices, one critical question arises: What package will best maintain device efficiency and longevity? The 20247 package, commonly used for SiC devices, is an exemplary choice. It offers excellent low-loss performance and superior thermal resistance, which are essential attributes for sustaining the high efficiency and longevity of the devices. This particular packaging choice is well-suited to meet the rigorous demands of high-power applications, such as EV charging and solar energy systems, where both efficiency and reliability are paramount.

Role of SiC in EV performance enhancement

Silicon carbide enhances the performance of electric vehicles in several key areas:

Faster charging times

SiC’s high efficiency and thermal conductivity contribute to faster and more reliable charging, reducing downtime and enhancing user convenience.

Improved thermal management

The ability to handle higher temperatures allows SiC devices to operate more efficiently under stress, prolonging their lifespan and reducing the likelihood of overheating.

Compact system design

The high system frequency potential of SiC makes it possible to design smaller and lighter components, which is vital for optimising the space and weight of EVs.

The ongoing developments in SiC technology are focused on expanding its application beyond just high-power settings to include a broader range of electronic components. These innovations are paving the way for SiC to play a more dominant role in the future of EVs and other high-demand electronics, offering a blend of performance and environmental benefits.

Addressing industry challenges and misconceptions

Despite its numerous benefits, the integration of SiC technology comes with challenges, particularly around its relative novelty in the market. As companies push the boundaries of SiC applications, they also work to dispel common misconceptions about its complexity and cost. The potential for SiC to reduce operational and maintenance costs substantially outweighs the initial investment, making it an increasingly attractive option for high-power applications.

The future of SiC in EV technology looks promising with ongoing research focused on improving durability and performance under extreme conditions. Innovations in packaging and integration techniques continue to emerge, paving the way for more sophisticated applications not only in automotive but also in renewable energy systems and industrial power solutions.

As the automotive industry continues to evolve, the role of silicon carbide in advancing electric vehicle technology becomes increasingly crucial. Its ability to drive efficiency, reduce costs, and improve performance positions SiC as a cornerstone of future developments in EV tech. For those looking to stay ahead in the fast-paced world of automotive innovations, embracing SiC technology offers a competitive edge that will define the next generation of electric vehicles. The practical application of SiC in EVs has demonstrated significant improvements in charging infrastructure and onboard power systems. Case studies and real-world applications, available through resources like IBS Electronics, showcase how SiC technology enhances the charging speed and efficiency of electric vehicles, contributing to the industry’s shift towards more sustainable mobility solutions.

This article is bassed on a webinar hosted by Diotec and IBS Electronics. It has been transcribed and curated by Akanksha Sondhi Gaur, Research Analyst and Technical Journalist at EFY.