The design is a 250W motor inverter without a heat sink. It features low standby power and sensorless motor control for various household applications.

Motor inverters, also known as variable frequency drives, play a crucial role in modern industrial and commercial applications by controlling the speed and torque of electric motors. These devices enable precise speed adjustments by varying the frequency of the electrical power supplied to the motor, enhancing both operational efficiency and energy conservation. Additionally, motor inverters contribute to extended motor life, reduced mechanical stress, and improved overall system stability. Their ability to finely tune performance leads to significant cost savings and helps organizations comply with stringent energy regulations, making them an indispensable component in today’s technology-driven environments. TIDA-010273, a reference design from Texas Instruments (TI), features a 250W high-efficiency motor inverter that operates without a heat sink, utilizing GaN IPM DRV7308.

The design showcases a low standby power configuration using UCC28911. It incorporates sensorless FOC motor control for a 3-phase PMSM, employing either FAST or eSMO observer technology. Compatible with both C2000 MCU and MSPM0 microcontroller daughter boards on a single motherboard, the design comes complete with hardware, GUI software, and firmware, all ready to use to facilitate quicker development and market launch.

The reference design can be utilized in various household applications to enhance efficiency and control. These include refrigerators and freezers, which consistently regulate temperatures using less energy. Heat pumps and indoor and outdoor air conditioning units benefit from inverters by optimizing climate control and reducing operational costs. In kitchen appliances such as cooker hoods, dishwashers, and mixer blenders, inverters contribute to quieter operation and improved appliance performance. Additionally, they are used in washers and dryers, adjusting motor speed to suit different fabric types and washing loads, and in residential fans, offering variable speed settings for enhanced comfort.

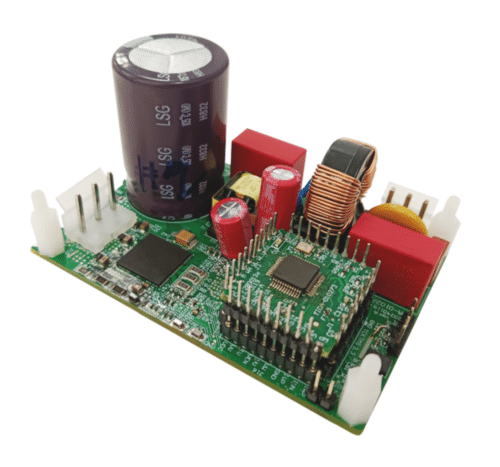

The design has an efficiency of over 99% and does not require a heat sink for up to 250W at a 15kHz switching frequency. It operates within a voltage input range from 165 to 265 VAC at 50/60Hz and has a board size of 80mm by 55mm. The design minimizes standby power usage and features a modular structure accommodating a C2000 or MSPM0 controller daughterboard on the same power motherboard. It supports sensorless Field Oriented Control (FOC) for motors, including FAST and eSMO observer, torque compensation, and automatic field weakening control. It also includes a graphical user interface (GUI) that aids in controlling, identifying, and monitoring the motor.

TI has tested this reference design. It comes with a bill of materials (BOM), schematics, assembly drawing, printed circuit board (PCB) layout, and more. The company’s website has additional data about the reference design. To read more about this reference design, click here.