Stanford University scientists have used a specialised electron microscope for the first time to explore the microstructure of promising soft semiconductors.

Organic mixed ionic-electronic conductors (OMIECs) are promising materials for next-generation batteries and electronics, offering exciting electrochemical properties. However, their molecular structure and electron transport mechanisms remain largely unexplored, a key challenge to overcome for commercial use.

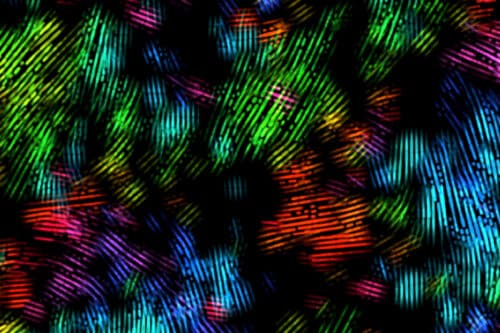

To address this knowledge gap, materials scientists at Stanford recently used a specialised electron microscopy technique designed for soft, “beam-sensitive” materials, such as biomolecules, to gain deeper insight into the structural inner workings of OMIECs and the reasons behind their favourable electrochemical properties. In OMIECs, much like water in a car battery, a liquid electrolyte is infused between polymer layers, acting as the medium through which ions travel between positive and negative poles to generate electrical current.

Elusive process

The dual stress of being soaked and electrically charged causes complex changes in the polymer’s structure. This phenomenon has intrigued researchers but has been difficult to visualise using traditional electron microscopy, as the beams easily damage these soft polymers.

With this novel technique, the team have observed how the soft, malleable polymer maintains its structural integrity as it expands. They believe the liquid crystal polymer of OMIECs stretches and bends to form a continuous electronic path around bubbles of electrolyte that emerge between the folded ribbons of polymer. Understanding this process sheds light on how the material performs under stress and could have significant implications for future research on OMIEC polymers.

Soft touch

Cryo 4D-STEM essentially freezes the material during the study. Still, instead of turning solid like ice, the electrolyte enters a vitrified state, allowing Salleo and the team to observe the microstructure in action. Tsarfati notes that once the polymer chains are swollen, they undergo minimal structural change, even during charging and discharging. This results in more efficient ion exchange with minimal strain on the material. This makes OMIECs particularly appealing for electronic applications due to their stability and efficiency under such conditions.