New programmable logic devices and no-code design tool reduce engineering design complexity, board space, time and costs.

What’s new

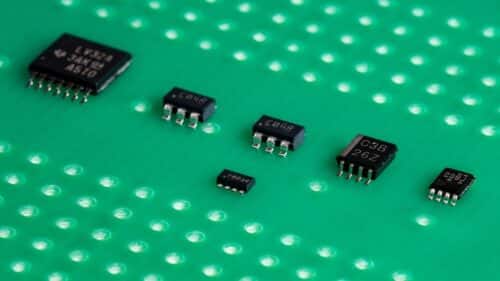

Building on its industry-leading logic portfolio, Texas Instruments (TI) today introduced programmable logic devices (PLDs) that empower engineers to streamline their logic designs for any application. With the ability to integrate up to 40 combinational and sequential logic and analog functions into one device, TI’s new PLD portfolio can help reduce board size as much as 94% – and lower system costs – compared to discrete logic implementations. Moreover, the new portfolio offers significant space savings compared to similar programmable logic devices on the market.

Leveraging TI’s easy-to-use InterConnect Studio tool, engineers can design, simulate and configure their devices for evaluation in minutes without the need for any software coding. InterConnect Studio expedites the logic design process with a drag-and-drop GUI and integrated simulation feature. Designers also benefit from click-to-program and direct ordering features that simplify programming and procurement, helping to accelerate time to market.

Why it matters

“Engineers are increasingly considering programmable logic devices as a way to reduce design complexity and board space, simplify supply chain management, and accelerate their time to market,” said Tsedeniya Abraham, vice president and general manager of Interface at TI. “But existing programmable logic devices are more complex than many applications require, involve programming expertise, or they come in limited packaging options. Our new programmable logic portfolio builds on TI’s 60 years of experience in logic design and offers small form factors in industry-standard packaging as small as 2.56mm 2 , low power consumption, AEC Q-100 qualification and a temperature range of -40°C to 125°C for applications including automotive, industrial and personal electronics.”

More details

TI’s PLD portfolio includes the industry’s smallest leaded package across all markets, measuring 2.1mm by 1.6mm with a 0.5mm pitch. This leaded package is 92% smaller than competing devices, supporting manufacturers’ need for solderability – at a fraction of the size. TI’s automotive-grade PLDs are as much as 63% smaller than their closest competitors. The portfolio also offers quad flat no-lead (QFN) packaging options that enable automated optical inspection, ensuring safety and long-term system reliability.

With quiescent current less than 1µA and 50% less active power than similar devices on the market, TI’s new PLDs offer low power consumption to help extend battery life in products such as electric vehicles, power tools, battery packs and gaming controllers.

All of TI’s new PLDs support general-purpose input/output, look-up tables, digital flip-flops, pipe delays, filters, and resistor-capacitor oscillators. The TPLD1201 and TPLD1202 devices also integrate analog functions such as analog comparators, with internal selectable voltage reference options and hysteresis. The TPLD1202 offers additional elements such as Serial Peripheral Interface, I 2 C, a watchdog timer and a state machine.