The design helps control thermal printers effectively, ensuring accurate printing even when the operating system is unpredictable.

Thermal printing is a critical technology widely used across various industries because it produces high-quality prints quickly and efficiently. Renowned for its speed, thermal printers significantly outpace traditional inkjet or laser printers, making them ideal for fast-paced environments such as retail and food services. They are cost-effective, relying solely on thermal paper or labels, eliminating the need for expensive ink or toner. These printers’ reliability and low maintenance further enhance their appeal, as they operate with fewer consumables and mechanical parts, reducing the likelihood of downtime due to malfunctions. The Programmable Realtime Unit – Industrial Communications Subsystem (PRU-ICSS) of the AM335x SoC facilitates realtime, deterministic GPIO control, functioning effectively even under a non-deterministic operating system. The reference design from Texas Instruments (TI) illustrates a specific application of the PRU-ICSS in directly managing a thermal printer module.

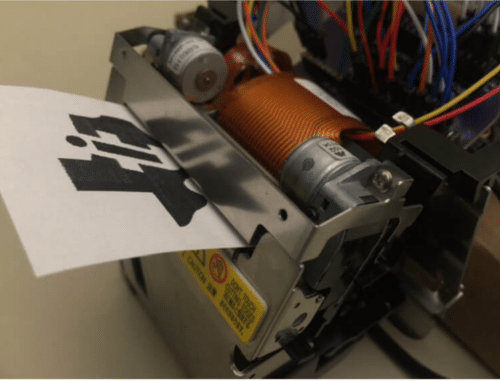

This design highlights a thermal printer application that utilizes the dual Programmable Realtime Unit and Industrial Communication Subsystem (PRU-ICSS), specifically the Sitara AM335x processor from Texas Instruments. Unlike typical thermal printing modules, which feature a controller board featuring a microcontroller to handle the printer’s mechanisms and interface with an application processor through serial or parallel connections, this design employs the PRU-ICSS to manage all control functions. This removes the need for a separate printer controller board to streamline the system architecture.

The main components of the thermal printer in this setup include stepper motors, which advance and cut the paper, and a semiconductor-based thermal printing element that creates images line-by-line on thermally sensitive paper. By integrating these functions within the PRU-ICSS, the design reduces components’ redundancy and enhances operational efficiency, ensuring high-quality print outputs.

The thermal printer demands precise input waveforms to effectively control the stepper motors and print head. Such agile control is challenging to achieve on a superscalar CPU architecture when operating under a high-level operating system, as it cannot guarantee the timing of inputs and outputs, leading to substandard print quality. In contrast, the PRU-ICSS excels at generating accurate real-time, deterministic control signals and waveforms. This capability stems from the PRU’s specialized architecture and its independence from the ARM host processor, enabling it to manage timing-critical tasks effectively.

The PRU-ICSS features two independent 32-bit RISC cores, each operating at 200 MHz. These cores are built on a single-cycle architecture, ensuring deterministic execution. Additionally, each PRU core has its own 8-KB Data RAM and shares access to 12 KB of Shared Data RAM.

TI has tested this reference design. It comes with a bill of materials (BOM), schematics, assembly drawing, printed circuit board (PCB) layout, and more. The company’s website has additional data about the reference design. To read more about this reference design, click here.