This design offers an advanced, reliable alternative to traditional mechanical buttons, improving durability and user satisfaction across multiple applications.

Many modern systems and devices, spanning industrial, automotive, and consumer sectors, rely on mechanical buttons for user interaction. Mechanical buttons have several drawbacks, such as increasing system costs, wearing out after several uses, and complicating design processes to protect the system from environmental factors like water, dust, and electromagnetic interference. Texas Instruments (TI) addresses these issues with the Touch on Metal Buttons With Integrated Haptic Feedback reference design. This design leverages the company’s inductive-to-digital and haptic technology to replace mechanical buttons with a touch-on-metal approach, while also offering realistic haptic feedback to enhance user experience.

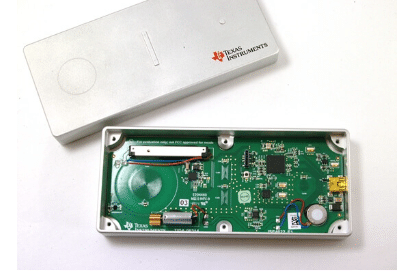

This reference designTIDA-00314, integrates inductance-to-digital converter (LDC) technology, providing a precise method for sensing button presses directly on a metal surface. The LDC technology measures the deflection of the metallic surface, acting as the button. By combining this with haptic drivers, the system can simulate the feel of a mechanical button press, delivering high-quality, programmable feedback that enhances the user’s tactile experience. This feature is particularly valuable in applications where a realistic, customisable response to user input is desired. The design is an example of implementing a robust system with environmental compensation and electromagnetic interference (EMI) protection. The inductive sensor coil, which plays a key role in button detection, was explicitly designed for this purpose and manually calibrated to ensure optimal performance. The sensor’s precise construction and the system’s environmental protections enable the touch-on-metal buttons to withstand contaminants like water, oil, and dirt. It ensures the system remains responsive even when the user is wearing gloves or operating in harsh or underwater environments, provided the system is adequately sealed.

This design allows for several button configurations. The options include a 20-mm button, two 3 mm x 10 mm buttons, and a 3-mm button, with the potential for alternative button layouts via different mechanical configurations. It supports programmable force sensitivity, allowing for various interactions from light touches to hard presses and customisable haptic waveforms to fine-tune the feedback sensation. The design replaces traditional mechanical buttons with high-resolution inductive sensing, allowing touch-on-metal interaction. It also enables EMI protection, sealing against contaminants, and configurable force sensitivity, making it versatile in various environments. The design is ideal for applications such as building automation, industrial and automotive interfaces, mobile devices, electronic points of sale, and appliances where mechanical buttons are being phased out in favour of more durable and flexible touch interfaces.

TI has tested this reference design. It comes with a bill of materials (BOM), schematics, assembly drawing, printed circuit board (PCB) layout, and more. The company’s website has additional data about the reference design. To read more about this reference design, click here.