These AEC-Q101-qualified devices feature ultra-low loss and high short-circuit tolerance, making them ideal for electric vehicle compressors, high-voltage heaters, and industrial inverters.

ROHM has introduced a new lineup of automotive-grade, AEC-Q101-qualified 1200V 4th Generation IGBTs, explicitly designed for high-efficiency and high-voltage applications in automotive and industrial sectors. These advanced IGBTs combine industry-leading low-loss characteristics with exceptional short-circuit resistance, making them well-suited for electric vehicle compressors, high-voltage heaters, and industrial inverters.

The initial lineup consists of four models—RGA80TRX2HR, RGA80TRX2EHR, RGA80TSX2HR, and RGA80TSX2EHR—offered in two discrete package types, TO-247-4L and TO-247N, alongside 11 bare chip variants (SG84xxWN). ROHM plans to expand this lineup to meet increasing demands driven by the trend toward higher voltage systems in automotive and industrial applications.

The key specifications are:

- VCES [V]: 1200

- Package Size [mm]16.0×25.87 (t=5.2)

- Storage Temperature (Min.)[°C]-55

- Storage Temperature (Max.)[°C]175

With the shift towards higher voltages in modern automotive and industrial applications, there is an increasing need for power devices that can manage high-voltage operations while offering efficient energy use, simplified cooling systems, and compact form factors. These IGBTs meet stringent automotive reliability standards and offer robust current interruption capabilities essential for short-circuit resistance in inverter and heater circuits.

To achieve these performance benchmarks, the company redesigned the device structure and packaging, enabling these 4th Generation IGBTs to achieve industry-low losses while maintaining a high withstand voltage of 1200V and an industry-leading short-circuit withstand time of 10µs (at Tj=25°C). The package further enhances reliability by including four terminals and meeting an 1100V effective voltage in “Pollution Degree 2” environments, reducing the design burden for manufacturers by ensuring optimal creepage distance.

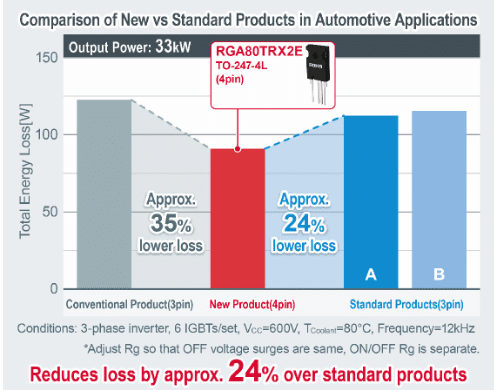

The packages incorporate a Kelvin emitter terminal, which supports high-speed switching with even lower losses. In a 3-phase inverter comparison, these packages reduced loss by 24% compared to standard products and by 35% versus conventional products, significantly boosting efficiency in drive applications. The company plans to continue enhancing this product family to support a wide range of high-performance, high-efficiency applications, including electric compressors, high-voltage automotive heaters, and industrial inverters.

For more information, click here.