Researchers at IISc developed a crystal-to-glass memory technology that operates with unprecedented energy efficiency.

A team of scientists led by the Indian Institute of Science (IISc) has discovered a novel method to convert crystalline materials into glass, using an energy level a billion times lower than traditional processes. The research, centred on indium selenide which is a layered ferroelectric material could reshape the future of memory storage in devices by significantly reducing power consumption and advancing phase-change memory technology, making it especially appealing for industries requiring compact, high-performance data storage.

The research shows that mechanical shocks generated by continuous electric current can achieve the crystal-to-glass transition without the high temperatures typically required. Traditional methods rely on heating materials to over 800°C, followed by rapid cooling that is a process that consumes substantial energy, especially in devices like phase-change RAMs and optical storage systems.

The discovery, involving collaboration between IISc, Penn Engineering, and MIT, has substantial implications for data storage applications. As phase-change memory (PCM) devices have traditionally faced power limitations, this new approach opens avenues for energy-efficient data storage, benefiting industries reliant on low-power, high-density memory solutions. It is anticipated that technology giants, cloud data centres, and electronic device manufacturers could harness this advancement for large-scale data storage applications, addressing the growing demand for sustainable, high-capacity memory. “This was extremely unusual,” says Gaurav Modi, former PhD student, Penn Engineering, describing the crystal structure disruption. “Normally, electrical pulses are needed to induce amorphization, yet here, a continuous current unexpectedly triggers the transition.”

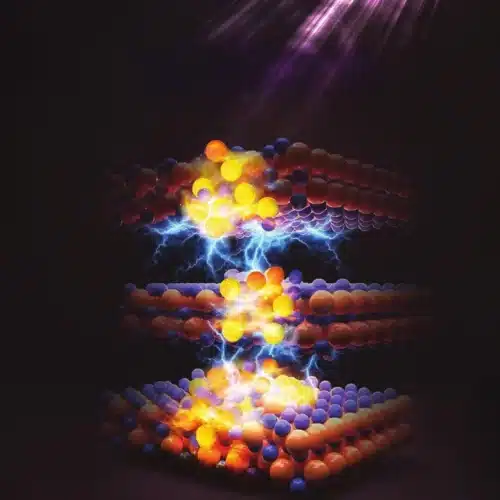

Using advanced in-situ microscopy tools, IISc’s researchers observed that continuous current induced a sliding effect between the indium selenide’s atomic layers. This movement, likened to tectonic shifts, formed domains which are small pockets with specific dipole moments thus, creating an earthquake-like effect. When these domains collide, mechanical and electrical shocks generate an ‘avalanche,’ causing the material to transition into glass. Shubham Parate, PhD student, IISc, shared his excitement about witnessing these phenomena unfold under an electron microscope: “It’s just goosebumps stuff to see all of these factors come to life and play together.”

Indium selenide’s unique properties, including its two-dimensional ferroelectric and piezoelectric characteristics, make it ideal for these low-energy transformations. The team, led by Ritesh Agarwal from Penn Engineering and Pavan Nukala from IISc, is now aiming to integrate this technology with complementary metal oxide semiconductor (CMOS) platforms to further its applications in commercial memory devices. This advancement could help phase-change memory systems achieve widespread adoption across consumer electronics, enhancing devices from smartphones to computers. The IISc team’s work points not only to a future of more efficient memory storage but also demonstrates how interdisciplinary research can yield radical developments.