The 8-channel lithium-ion battery testing system is designed for high-demand uses, offering reliable charging control and temperature checks.

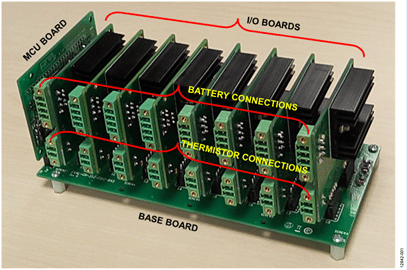

The multichannel lithium ion battery testing system reference design from Analog Devices (ADI) is a precise, cost-effective, 8-channel battery testing setup for single-cell lithium-ion (Li-ion) batteries with open circuit voltages (OCV) ranging from 3.5 V to 4.4 V. Demand for Li-ion batteries is high across various applications, from low-power devices like laptops, mobile phones, and portable wireless terminals to high-power uses in hybrid and all-electric vehicles (HEV/EV). Accurate and dependable test systems are essential for these batteries.

The circuit features the ADP5065 fast-charging battery manager, which provides flexible, efficient, and stable charging control with a low-cost, compact PCB footprint and ease of use over traditional discrete solutions. For precision data acquisition and processing, the ADuCM360 analog microcontroller is employed to measure battery voltage, current, and temperature. Equipped with a high-precision ADC, DAC, and an on-chip microcontroller, the ADuCM360 enables fully self-contained control over the charging and discharging processes.

The ADP5065 handles complete charging control for single-cell Li-ion or lithium polymer batteries, supporting constant current (CC), constant voltage (CV), and trickle charge (TC) modes. The TC mode is particularly useful for safely testing deeply discharged batteries. Leveraging a DC-DC switching converter architecture, the ADP5065 achieves higher charging efficiency than traditional linear regulators.

For reliable performance, the battery manager integrates features such as thermal management, battery fault detection, and fault recovery. Its charging parameters—including fast charging current, termination current, and termination voltage—are programmable via an I2C interface. This programmability allows the battery manager to accommodate various types of Li-ion batteries, making it a versatile and complete battery charging and testing controller.

The analog front end is designed with a fully differential configuration, delivering high common-mode rejection ratio (CMRR) and strong immunity to common-mode and ground noise generated by large currents during charge and discharge cycles. Additionally, the system’s architecture supports easy expansion of channels, enabling reduced testing time and cost per battery.

The electronic load (E-load) circuit offers a programmable constant-current load. It utilizes the AD8601 precision CMOS op-amp, four 1 W, 1% power resistors, and two SIR464 power MOSFETs. Most Li-ion batteries should not be charged at temperatures below 0°C or above 60°C, with fast charging and discharging limited to a range of 10°C to 45°C. Beyond safety concerns, battery performance can vary significantly with temperature. Accurate temperature measurement is essential to ensure both the consistency of test results and overall safety.

ADI has tested this reference design. It comes with a bill of materials (BOM), schematics, assembly drawing, printed circuit board (PCB) layout, and more. The company’s website has additional data about the reference design. To read more about this reference design, click here.