This design allows for multiple operating modes, including constant speed, torque, and power, ensuring flexibility and adaptability in different usage scenarios.

The demand for compact, efficient motor controllers is surging alongside the growth of micro-mobility devices such as e-scooters and e-bikes. These devices, driven by the push for environmentally friendly and fuel-efficient transportation, require advanced control systems to meet the needs of electrification in transportation. A standalone motor controller solution tailored for BLDC (Brushless DC) and PMSM (Permanent Magnet Synchronous Motor) systems provides an ideal answer to this demand. Supporting power levels up to 3kW and voltage inputs as high as 85V, these controllers are optimized to meet the operational needs of high-performance e-mobility systems.

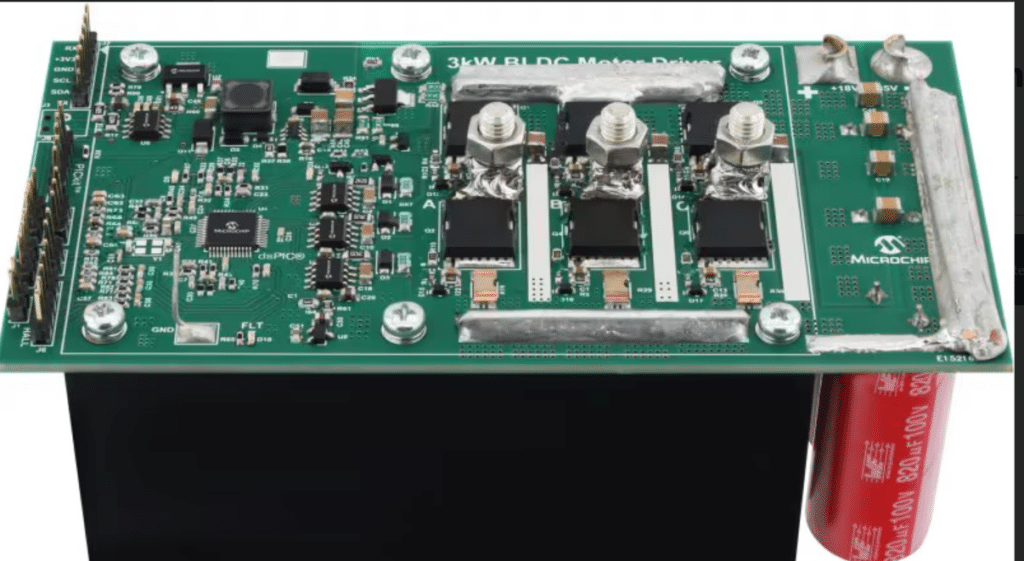

The dsPIC33CK64MP105 DSC motor controller design by Mircochip Technology is designed for high output, offering a continuous 50A RMS and peak current levels of up to 150A for brief periods. This capability allows the controller to handle high demands without compromising on efficiency. It features an 18–85V input voltage range, suitable for up to a 20s battery pack, with an XT90-type connector for quick and secure connections. Based on Field Oriented Control (FOC) with HALL sensors, the system’s control algorithms ensure precise control over the motor’s torque and speed.

Enhanced control features are integrated to optimize performance, such as Maximum Torque Per Amp (MTPA) for IPMSM motors and Field Weakening (FW) for an extended power range. At the heart of the motor’s power delivery system is a robust three-phase inverter stage. Utilizing three MIC4101 (or MIC4104) 100V half-bridge MOSFET gate drivers and six low RDS(on) MOSFETs, this stage minimizes resistance and heat, maximizing power efficiency. The current sensing mechanism relies on three low-side shunt resistors (500 µΩ each) placed on each phase, and PWM switching frequencies are configurable from 8 to 20 kHz, giving designers additional control over efficiency and noise reduction.

For enhanced safety, integrated protections are included, such as overvoltage and undervoltage safeguards on the BUS, motor phase overcurrent detection, and over-temperature protection on the inverter stage MOSFETs. This controller also supports regenerative braking, helping to improve overall energy efficiency. Additional design features include system bias generation with a 12V buck regulator, as well as 5V and 3.3V LDOs, and temperature monitoring via the MCP9700A sensor.

To facilitate connectivity and ease of control, the controller is equipped with CAN communication, alongside auxiliary connections for throttle input, voltage monitoring, I2C, UART, and Bluetooth® options. Additionally, the EeZeeFOC Driver GUI provides an intuitive interface for motor drive optimization. This compact motor controller measures 13 x 7 x 6 cm, making it highly suitable for micro-mobility applications where space is at a premium. This comprehensive, high-power solution is poised to support the growing demands of the micro-mobility market, promoting efficient, high-performance electric transportation.

Microchip has tested this reference design. It comes with a bill of materials (BOM), schematics, assembly drawing, printed circuit board (PCB) layout, and more. The company’s website has additional data about the reference design. To read more about this reference design, click here.