Table of Contents

Introduction

Electric motors are pivotal in powering household items and propelling large-scale industry appliances. The mechanical motion produced by motors is what makes them essential in applications that require efficiency, reliability, and precise control over movement.

At its core, an electric motor is a device that converts electrical energy into mechanical motion. Understanding the basic concept of an electric motor is crucial before delving into the types and specific applications. Electric motors operate based on a fundamental principle of physics: electromagnetism. When an electric current flows through a conductor (such as a coil of wire), it generates a magnetic field.

If this conductor is placed within a larger magnetic field, the interaction between the two fields generates a force, causing the conductor to move. This motion is harnessed to perform mechanical work, such as rotating a fan. This movement is rotary in most motors, meaning the conductor rotates within a magnetic field. By carefully designing the motor’s components, such as the rotor and the stator, engineers can control the speed, direction, and torque produced by the motor.

Electric motors have a fascinating history of development, starting with the earliest forms of motors in the 18th century. The journey of motor evolution is the greatest example of humanity’s quest to harness electricity and transform it into useful mechanical power.

But why did engineers and inventors feel the need to experiment with different motor designs, like AC and DC, and eventually branch out into specialized motors?

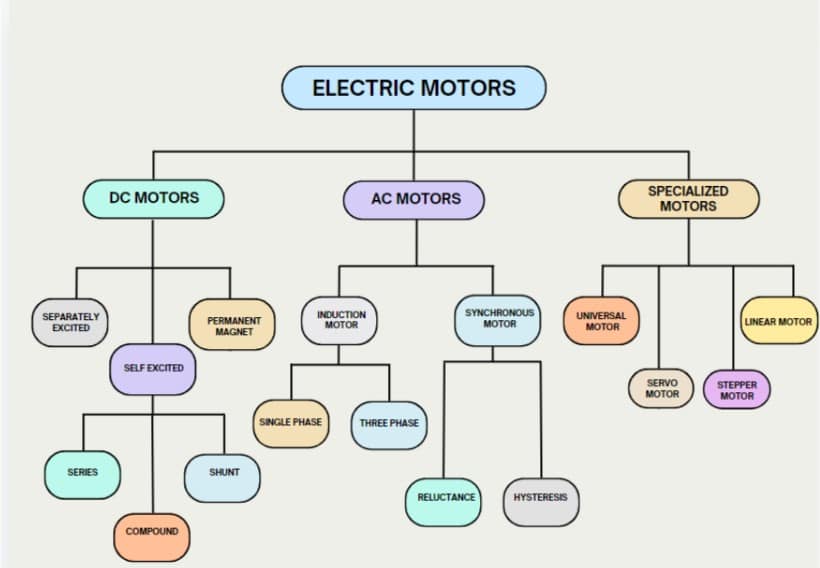

Types of Electric Motors

Electric motors have come a long way, with their journey starting from the DC motor. Early experiments in electromagnetism showed that a rotating magnetic field could power mechanical devices, making DC motors the first practical solution.

However, they had some drawbacks. DC motors used brushes and commutators, which wore out quickly and needed constant maintenance. They also weren’t great for transmitting electricity over long distances, leading to significant energy loss.

As electrical networks expanded, AC motors became more common. AC was more efficient for long-distance power transmission because it could easily change voltage levels via transformers, making it ideal for large-scale distribution.

However, while AC motors were powerful, unlike their DC counterparts, they lacked fine speed control and torque adjustment. This sparked further innovation, as engineers realized that no single motor could meet every need.

Today, we have a wide range of motors, each offering unique benefits regarding duty cycle, RPM control, and torque. Understanding their strengths and how they operate for specific applications is essential.

Now, let’s explore the fascinating world of motor types, their applications, and how they work.

DC Motor

Definition: Operates on direct current (DC) and converts electrical energy into mechanical energy.

Working principle: A current-carrying conductor in a magnetic field experiences a force that generates torque and causes the motor to rotate. The interaction between the magnetic field and the current flowing through the armature windings produces the rotation.

Application: Electric vehicles, cranes, hoists, elevators, industrial machinery, and toys.

1.1. Separately Excited Motor

Definition: A DC motor where the field winding is powered by an external independent source, separate from the armature winding.

Working principle: The motor’s field and armature windings are fed by different power sources. This allows precise control over both the magnetic field and the armature current, providing greater flexibility in controlling speed and torque.

Application: Precision control applications, high-performance industrial drives, and research equipment. Precision control applications, high-performance industrial drives, and research equipment.

1.2. Self-Excited Motor

Definition: A DC motor where the field winding is connected directly to the armature circuit and the motor itself provides the necessary excitation.

Working principle: The same power source provides current for both the field and armature windings. As the armature rotates, it induces a voltage in the field winding, which strengthens the magnetic field, and thus the motor generates torque.

Application: Fans, pumps, blowers, and industrial machines.

1.2.1. Series Motor

Definition: A type of self-excited motor where the field winding and armature are connected in series.

Working principle: Since the same current flows through both the field and the armature, the motor develops high torque at low speeds. However, the speed decreases with increasing load.

Application: Cranes, hoists, and electric locomotives.

1.2.2. Compound Motor

Definition: Combines the characteristics of series and shunt motors, with both series and shunt field windings.

Working principle: The motor has a series field winding for high starting torque and a shunt field winding to stabilize speed. This combination offers a balance between speed regulation and high torque.

Application: Elevators, rolling mills, presses, and conveyors.

1.2.3. Shunt Motor

Definition: A DC motor where the field winding is connected in parallel with the armature winding.

Working principle: The parallel connection ensures that the field current is nearly constant, providing consistent speed, even under varying loads.

Application: Lifts, fans, conveyors, and pumps.

1.3. Permanent Magnet

Definition: A DC motor where the magnetic field is produced by permanent magnets instead of a field winding.

Working principle: Permanent magnets create a constant magnetic field, so the armature interacts with this field to produce rotation without the need for an external field current.

Application: small devices like toys, portable electronics, battery-powered tools, and appliances.

AC Motors

Definition: Operates on alternating current (AC) to convert electrical energy into mechanical energy.

Working principle: The alternating current produces a rotating magnetic field in the stator, which induces current in the rotor, creating motion. AC motors can operate synchronously or in induction.

Application: Industrial machinery, household appliances, HVAC systems, and fans.

2.1. Induction Motor:

Definition: An AC motor where the rotor is not electrically connected but instead induced by the stator’s rotating magnetic field.

Working principle: The rotating magnetic field generated in the stator induces current in the rotor, which causes the rotor to rotate at a speed slightly slower than the stator field.

Application: Pumps, fans, conveyors, and compressors.

2.1.1. Single Phase Motor

Definition: An induction motor that operates on a single-phase AC supply.

Working principle: A single-phase current generates a pulsating magnetic field in the stator, which requires an auxiliary mechanism to start rotation.

Application: Small household appliances like fans, refrigerators, and washing machines.

2.1.2. Three Phase Motor

Definition: A motor that runs on a three-phase AC power supply.

Working principle: A rotating magnetic field is created by the three-phase supply, which induces current in the rotor, causing it to rotate. This motor is more efficient and powerful than single-phase motors.

Application: Industrial applications, such as compressors, pumps, large machinery, and elevators.

2.2. Synchronous Motor

Definition: An AC motor where the rotor’s speed matches the speed of the rotating magnetic field in the stator.

Working principle: The rotor, using permanent magnets or electromagnets, locks in step with the rotating magnetic field produced by the stator, rotating at synchronous speed.

Application: High-precision applications, such as robotics, timers, and conveyors.

2.2.1. Reluctance Motor

Definition: A synchronous motor that uses the phenomenon of magnetic reluctance to produce motion.

Working principle: The rotor aligns itself with the magnetic field produced by the stator to minimize magnetic reluctance, generating torque.

Application: Energy-efficient processes, automation systems, and precision control applications.

2.2.2. Hysteresis Motor

Definition: A type of synchronous motor that utilizes the magnetic hysteresis of materials to operate.

Working principle: The rotor develops torque through the lagging of magnetic domains within the rotor material relative to the stator’s rotating field, resulting in smooth and quiet operation.

Application: Precision equipment like record players, clocks, and instrumentation.

Specialized Motors

Definition: Motors that operate on unique principles, often used in specialized applications where traditional AC or DC motors are not suitable.

Working principle: These motors operate using specific mechanisms such as linear motion, electronic control, or a combination of both AC and DC principles.

Application: Specialized machinery, robotics, and precision instruments.

3.1. Universal Motor

Definition: A motor that can run on both AC and DC power.

Working principle: It is a series-wound motor where the same current flows through the rotor and stator. This motor provides high-speed operation and works on both types of current.

Application: Power tools, vacuum cleaners, and kitchen appliances.

3.2. Servo Motor

Definition: A motor that provides precise control of angular position, velocity, and acceleration using feedback.

Working principle: A closed-loop system uses feedback from an encoder or sensor to adjust the motor’s movement based on the desired input, allowing precise control over motion.

Application: Robotics, CNC machinery, and automation systems.

3.3. Stepper Motor

Definition: A motor that moves in discrete steps, providing accurate position control without the need for feedback.

Working principle: The motor rotates by moving in fixed steps, where each pulse sent to the motor moves it by one step, allowing for high precision in positioning.

Application: 3D printers, CNC machines, and robotic arms.

3.4. Linear Motor

Definition: A motor that produces motion in a straight line rather than rotational motion.

Working principle: The stator and rotor are laid out linearly. As the magnetic field moves along the stator, the rotor follows, creating linear motion.

Application: conveyor systems and actuators.

Understanding Motor Symbols

| Motor Types | Symbolic Representation |

| Electric Motor | |

| DC Motor Series Motor Shunt Motor Compound Motor Permanent Magnet Motor | |

| AC Motor Single Phase Series Motor Three-Phase AC Motor Synchronous Motor | |

| Stepper Motor | |

| Linear Motor |

Practical Applications of Electric Motors

Electric Fans

Electric motors are the most important component that helps in the operation of electric fans. Typically, these fans use small single-phase induction motors that provide sufficient torque to spin the blades.

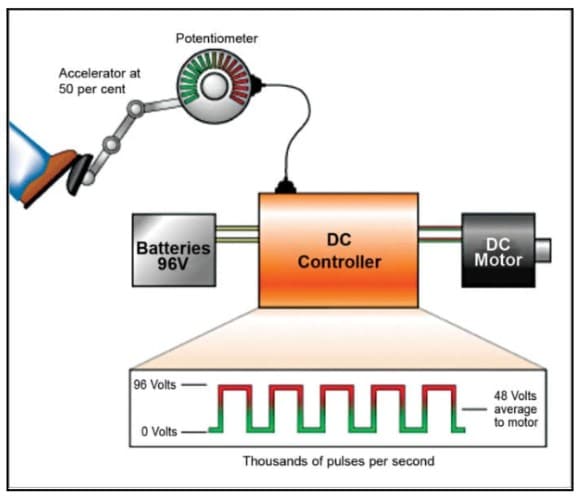

Electric Vehicles

Electric vehicles use powerful electric motors to drive their wheels, offering high torque, which is a significant advantage over internal combustion engines. These vehicles typically use DC or AC motors, such as permanent magnet synchronous motors or induction motors. EV motors are known for their efficiency, quiet operation, and capability to regenerate energy through braking, further increasing their overall energy efficiency.

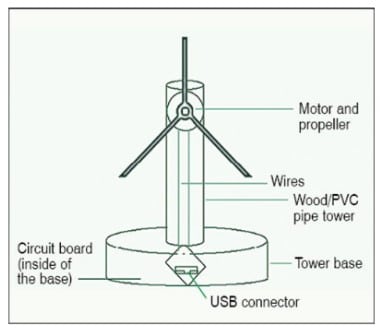

Wind Turbines

When wind rotates the turbine blades, the motor (acting as a generator) converts the mechanical energy of the rotating blades into electrical energy. These motors are typically large, high-efficiency synchronous generators designed to handle fluctuating wind speeds while maintaining stable power output.

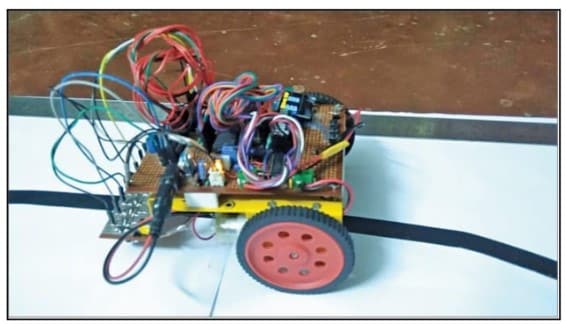

Robotics

Electric motors, especially servo and stepper motors, are fundamental to the operation of robotic arms and automated machinery. These motors allow robots to perform precise, controlled movements in tasks like assembly, welding, and material handling. Robotics often require motors with advanced control capabilities, including speed, torque, and position feedback.

Phone Vibration

Phone vibrations are powered by a tiny DC motor known as a vibration motor or vibrator motor. These motors are designed with an off-center weight attached to the motor’s shaft. When the motor spins, the uneven weight causes the phone to vibrate.

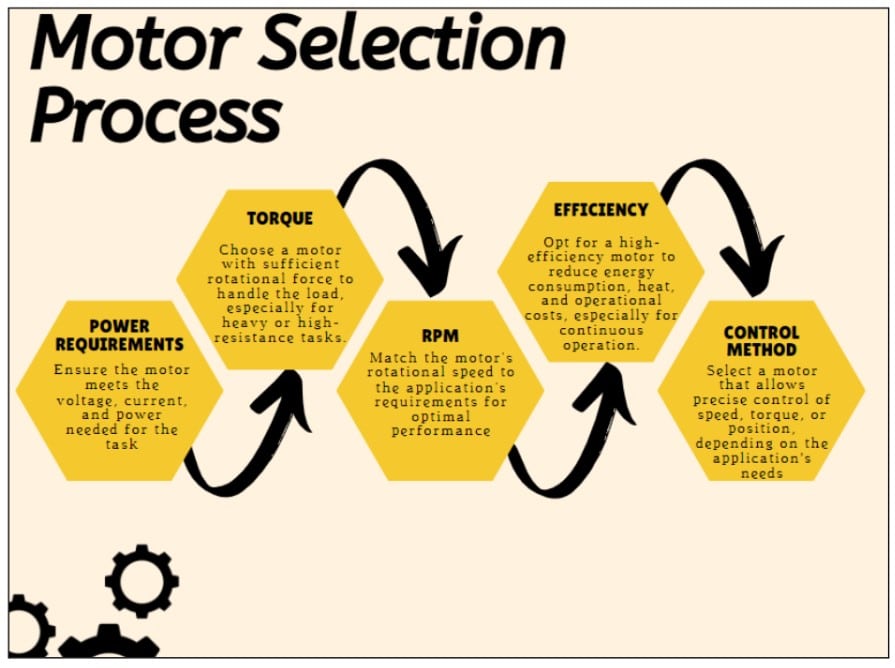

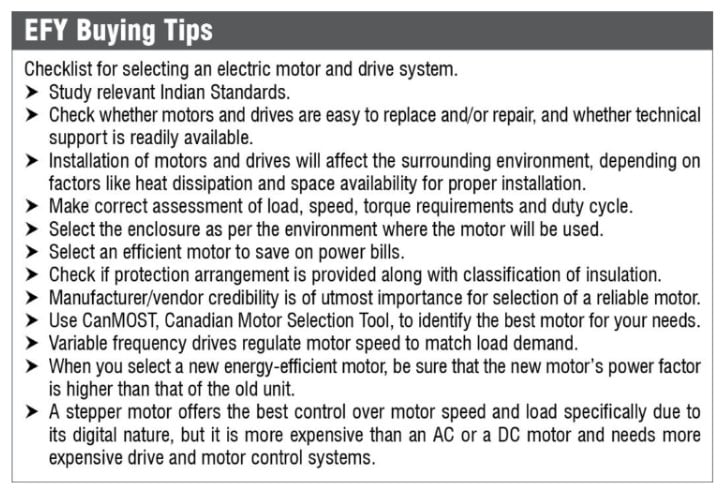

Motor Selection Guide: What to Consider

For an in-depth guide on selecting the right motor, be sure to check out our article on Selecting an Electric Motor and Drive System and Selecting the Right Motor for Your Design.

Drive Your Creativity: Electric Motor Projects to Try

- Building Your Own ESC/Servo Tester: Mini ESC and Servo Tester help you efficiently diagnose and test Electronic Speed Controllers (ESCs) and servo motors.

It enhances your hands-on skills in circuit design and troubleshooting, making it ideal for hobbyists in the RC and robotics fields.

- Controlling a Stepper Motor Using a Rotary Encoder: This project showcases how to control a Stepper motor using a rotary encoder and Raspberry Pi

- Water Pump Controller: This exciting project is a simple water pump controller circuit that regulates the water level in an overhead tank.

It uses a step-down transformer, a 24V AC double-changeover relay, two floats, and two micro switches to efficiently control the pump.

- LDR-Based DC Motor Speed Control: This project features an LDR-based DC motor speed control system

FAQs (People Also Ask)

What is the difference between AC and DC motors?

Ans. AC motors run on alternating current, while DC motors run on direct current. AC motors are more commonly used in industrial applications, while DC motors are often used in devices requiring precise control like electric vehicles.

Which motor is best for electric vehicles?

Ans. Brushless DC motors (BLDC) are typically preferred for electric vehicles due to their high efficiency and low maintenance.

What is the advantage of using a brushless motor?

Ans. Brushless motors offer higher efficiency, require less maintenance, and have a longer lifespan because they eliminate the friction and wear associated with brushes in traditional motors.

What is a stepper motor, and where is it used?

Ans. A stepper motor is a type of DC motor that moves in discrete steps, making it ideal for precise control in applications like 3D printers and robotics.

What is the difference between a synchronous motor and an induction motor?

Ans. A synchronous motor rotates at a speed that is synchronized with the supply frequency, while an induction motor operates slightly slower due to slip.

Can electric motors be used for regenerative braking?

Ans. Yes, many electric motors, especially in electric vehicles, can be used for regenerative braking, where the motor converts kinetic energy back into electrical energy to recharge the battery.