Canadian team have developed a 3D software suite for accurate industrial measurements and inspections for betterment of factory automation tasks.

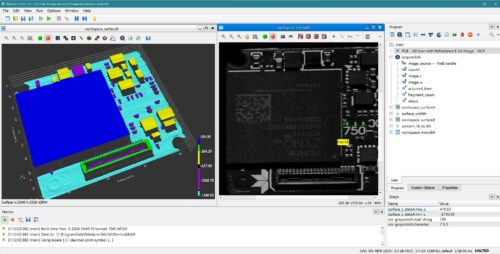

Team from Teledyne DALSA, Canada have developed the ‘Z-Trak’ 3D applications studio, a comprehensive suite of tools designed for in-line 3D measurement and inspection. This software, built to function with the Z-Trak laser profiler family, simplifies complex industrial tasks such as assessing dimensions and inspecting surfaces of various types. Its application spans multiple industries, including electronics, automotive, semiconductors, and packaging.

It is tailored to handle diverse operational needs, such as measuring object thickness, analysing weld seams, inspecting glue patterns, and detecting defects on curved or flat surfaces. A notable feature is its ability to process scans of objects with varying geometries and materials, ensuring accuracy in challenging environments. The software is particularly relevant for manufacturers, quality control teams, and automation engineers in industries requiring precision measurements for complex designs or large-scale production.

“The system integrates seamlessly with multiple sensors, enabling 360° inspection and precise height resolution,” said the research team. This multi-sensor approach ensures comprehensive analysis while avoiding occlusions, a critical need in automated production lines. The software combines 3D visualisation with simultaneous processing of 3D scans and 2D grayscale reflectance data, offering a holistic view of the inspection process.

Accessibility is a core strength of this suite of tools. It is compatible with Sherlock 8.30 or higher, a no-code, graphical development platform widely used in industrial applications. This integration facilitates easy deployment and rapid adoption across production floors.

By addressing the growing need for precision and efficiency, the new suite of tools set a new benchmark in industrial imaging and automation, making it a valuable tool for advancing factory workflows across sectors.