As of 2024, this startup is recognised for its innovative desktop pick-and-place machine, transforming electronic prototyping and small-scale manufacturing.

Efficiency, accuracy, and adaptability are the future of prototyping and small-scale manufacturing. Dr Unnikrishnan emphasises their desktop pick-and-place machine is a development for engineers, enabling swift idea-to-product transformation. Its capability to manage loose components and customisation makes it perfect for speeding up R&D and small-batch production, empowering users with greater control.

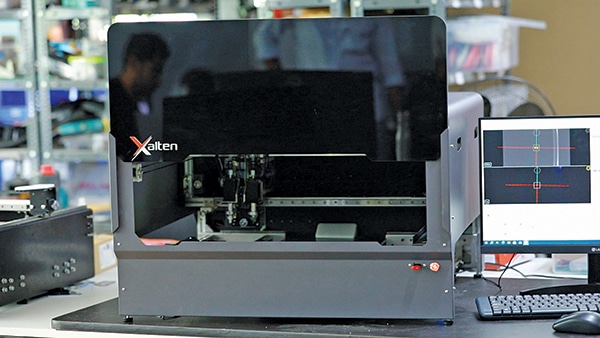

Headquartered in Kochi, India, Xaltan Systems was incorporated in 2023 by three co-founders, Dr Unnikrishnan K.C., Ajith Narayanan, and Suresh Gopinathan. (The groundwork had been ongoing since 2017.) Their flagship product, described as a ‘robotic arm for electronics,’ significantly streamlines the process of placing tiny components on circuit boards, offering a precise and adaptable solution, as Unnikrishnan states.

The startup’s pick-and-place machine stands out due to its advanced vision systems and accurate motion systems, allowing it to handle components as small as 0.3mm by 0.5mm with pinpoint accuracy. Its customisable feeders are designed to handle an extraordinary range of components, from tiny resistors and capacitors to larger IC packages, ensuring seamless transitions between different board designs. A key innovation is its Loose Part Feeder system, a rare feature in similar machines, particularly those from Chinese competitors. This machine was developed amidst the global chip shortage and the challenges posed by the Covid-19 pandemic, which forced the team to overcome significant design hurdles, including eliminating costly external assembly reliance.

The startup manufactures its products in-house at its Kochi facility, ensuring high-quality control and the ability to customise quickly. This strategy also protects their intellectual property. Ajith emphasises that “the machine, which offers a resolution of ±0.01mm and placement accuracy of ±0.05mm, is ideal for small-scale and batch production.” The company has expanded its product line to include reflow ovens and solder paste dispensers, catering to the diverse needs of modern electronics manufacturers.

The need for a prototyping solution emerged in 2017 due to inefficiencies and high costs associated with manual handling and reliance on external assembly houses, which were unsuitable for experimentation. This led to the decision to build a pick-and-place machine, initially underestimated in complexity but later revealed to demand significant precision-related problem-solving. By 2019-2020, after overcoming numerous technical challenges, the first machine version was developed. However, the Covid-19 pandemic introduced new obstacles, including a critical chip shortage that forced a re-evaluation of design and components. These challenges, along with internal strategic shifts, led to a regrouping under the ‘Xaltan Systems’ banner and a transition to an open source software base, ultimately resolving many of the difficulties encountered during development.

The machines deliver performance with good resolution, placement accuracy, and speeds up to 3000 CPH, making them ideal for small-scale and batch production. Integrating advanced hardware and software, they feature a custom vision system and flexible feeders to manage various component sizes and orientations efficiently. In 2020, the company expanded its product line to include reflow ovens and solder paste dispensers, further enhancing its reputation. These machines are now recognised for their precision, versatility, and quick changeover capabilities, redefining desktop PCB assembly.

Committed to sustainability, they adhere to the restriction of hazardous substances (RoHS) directive, ensuring environmentally friendly manufacturing processes. Their energy-efficient machines consume minimal power, supporting sustainable practices. The company has received substantial support from the Ministry of Electronics and Information Technology (MeitY), which has been instrumental in their product development and market expansion efforts. The Technology Development Board (TDB) had also recognised this innovation with an award in 2022. Maker Village, Kochi, and the Kerala Startup Mission (KSUM) have also supported and encouraged the effort all through.

The startup aims to expand its product line to handle more complex production requirements and higher volumes. It is exploring international markets and seeking partnerships with distributors, component suppliers, and academic institutions. The company is particularly interested in channel partners with strong technical expertise in electronics manufacturing for global distribution. While currently not engaged in academic collaborations, it remains open to such partnerships to bolster its R&D efforts and continue driving innovation in its field.