New thin-film technology improves durability of solar cells and sensors, with broad industrial applications.

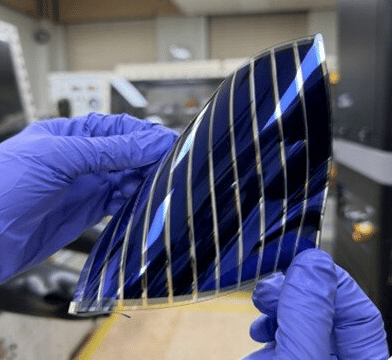

A research team has discovered an innovative thin-film material that promises to enhance the durability of electronic devices, including solar cells and sensors. This next-generation technology was developed by the Korea Institute of Materials Science, South Korea and can withstand rigorous mechanical stresses, such as rolling and unrolling, without compromising performance.

This discovery addresses a critical challenge faced by conventional energy and electronic devices. Thin-film materials, particularly those with layered structures, are prone to defects during manufacturing or use, especially when subjected to roll-to-roll production processes. The team’s new material overcomes this by significantly improving the mechanical durability of devices, preventing issues like delamination, which often occurs when layers of the material separate.

The team’s approach combines flexible organic materials with robust inorganic materials in a dual-layer structure. The study introduces a bilayer electron transport layer (ETL) using polyethyleneimine ethoxylated zinc oxide nanoparticles (PE-ZnO) and protonated polyethyleneimine (p-PEIE) for flexible organic solar cells (OSCs) and photodetectors (OPDs). This configuration enhances the power conversion efficiency (PCE) of OSCs up to 15.5% and demonstrates outstanding mechanical stability, maintaining 97% efficiency after 5000 sliding cycles. The bilayer ETL’s scalability, evidenced by large-area flexible OSCs with a PCE of 12.63%, underscores its practical viability for renewable energy and light sensing technologies. This novel combination enhances the material’s ability to withstand both physical and chemical stresses, allowing it to endure in a variety of environments. The result is a more resilient device capable of maintaining high efficiency through extended use.

One key application of the material is in flexible devices, where it acts as an interfacial layer between transparent electrodes and active layers, such as those found in solar cells and displays. This not only improves the bonding between the electrodes and active materials but also boosts the overall durability of the device.

Dr Dong-Chan Lim, the lead researcher, emphasised the technology’s potential for industrial impact. “This technology not only significantly improves production yields in roll-to-roll manufacturing processes using film-based flexible substrates but is also applicable to diverse downstream industries such as energy, displays, and robotics,” he noted. This development promises to increase the localisation rate of core materials, ultimately strengthening the competitiveness of critical industries.