What if memory could be faster, more efficient, and less powerful? A new approach to MRAM might have the answer. Learn more!

Magnetoresistive random access memory (MRAM) is a non-volatile memory that operates fast, stores more data, and works with CMOS technologies. MRAM stores data using magnetic tunnel junctions (MTJs) instead of transistors and capacitors. So why isn’t MRAM widely used? Current systems need high power for write operations, making them impractical for high-performance applications. However, researchers at Osaka University in Japan have found a way to make MRAM more energy-efficient. Their innovative design uses electric fields instead of large currents for data writing.

Conventional dynamic RAM (DRAM) stores data using transistors and capacitors, but the data is volatile and requires constant power to be retained. In contrast, MRAM stores data using magnetic states, such as magnetization orientation, allowing for non-volatile storage.

Current MRAM devices use electric current to switch the magnetization vectors of magnetic tunnel junctions, similar to switching capacitor charge states in DRAM. However, the writing process requires a large current, causing Joule heating and increased energy consumption.

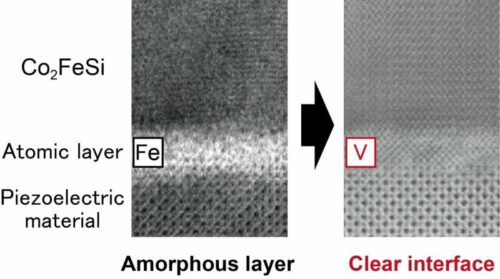

The breakthrough involves a multiferroic heterostructure that switches magnetization vectors directly using an electric field. This eliminates the need for high currents. The effectiveness of this approach is measured by the converse magnetoelectric (CME) coupling coefficient, which indicates how strongly magnetization responds to an electric field. While earlier designs had high CME coefficients, inconsistencies in the ferromagnetic layer reduced reliability and efficiency.

The team added an ultra-thin vanadium layer between the ferromagnetic and piezoelectric layers to solve this. This improved the interface, enabling precise control of magnetic properties and enhancing the CME effect. The new structure also achieved stable magnetic states at zero electric fields, making non-volatile binary data storage possible.

This MRAM technology could transform fields like AI by providing energy-efficient, reliable memory solutions. However, it’s still in the research stage. Whether it becomes practical for real-world use remains to be seen.

Reference: Takamasa Usami et al, Artificial Control of Giant Converse Magnetoelectric Effect in Spintronic Multiferroic Heterostructure, Advanced Science (2024). DOI: 10.1002/advs.202413566