The reference design enables easy heart rate, SpO2, and BPT monitoring integration into wearables and medical devices, with customizable firmware and sensor support.

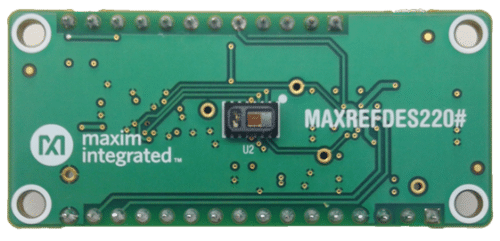

The MAXREFDES220 is a reference design from Analog Devices (ADI) that quickly measures heart rate, SpO2, and BPT with reflective photoplethysmography (PPG). The pre-programmed microcontroller, MAX30101, uses a 1.8V power supply and a separate 5.0V supply for the internal LED. Many device settings can be adjusted via the microcontroller. The module can be powered down through software, consuming zero standby current while keeping the power rails on.

The reference design suits engineers working on designs involving health monitoring devices such as wearables or medical instruments that measure heart rate, SpO2, and BPT. This reference design helps design engineers by providing a ready-made solution with key components and functionality, allowing them to integrate these measurements into their products quickly. The reference design also helps design engineers by providing a ready-made solution for quickly integrating heart rate, SpO2, and BPT measurements into their products. With pre-programmed microcontroller settings, adjustable parameters, and low-power features, engineers can easily configure the design to suit their needs.

The MAX32664 is a small, low-cost, power-efficient sensor hub for finger-based microcontroller applications. It collects and processes PPG and accelerometer data through an I2C interface and connects to the host via a second I2C interface with a dedicated command set. The MAX32664A is for heart rate and SpO2, while the MAX32664D adds BPT functionality. The reference design can be configured for either version.

A Windows-based GUI configures the sensors and displays heart rate and SpO2 data. It also allows sensor output to be logged for offline review. The reference design can be reprogrammed with BPT, heart rate, and SpO2 firmware, and a.6, an Android app can show the results. The included MAX32630FTHR board simulates a host system for easy development. The source code for the MAX32630FTHR firmware is available on the Arm Mbed site, enabling custom host development on any platform.

The pre-programmed microcontroller, with firmware drivers and algorithms, acts as a sensor hub when paired with compatible sensor devices. It processes data and sends it to a host device, enabling customers to access raw and calculated data from Maxim’s optical sensors while maintaining low power consumption. Its small form factor makes it suitable for compact applications. Integrated into the reference design solutions, the MAX32664 helps accelerate time to market. It shares the same hardware as the MAX32660 but includes a pre-programmed bootloader for in-application programming (IAP) of the algorithms and sensor drivers. The sensor hub features a fast-mode I2C slave interface for host communication and a second I2C interface for sensor connections.

ADI has tested this reference design. It comes with a bill of materials (BOM), schematics, assembly drawing, printed circuit board (PCB) layout, and more. The company’s website has additional data about the reference design. To read more about this reference design, click here.