In water-level controllers for tanks, a DC current is passed through the metallic probes fitted in the water tank to sense the water level. This causes electrolysis and corrosion of probes, inhibiting the conduction of current and degrading its performance. As a consequence, probes have to be replaced regularly to maintain proper current flow. The liquid level alarm given here overcomes this problem. A 1kHz AC signal is passed through the probes, so there will be no electrolysis and therefore the probes last longer.

In water-level controllers for tanks, a DC current is passed through the metallic probes fitted in the water tank to sense the water level. This causes electrolysis and corrosion of probes, inhibiting the conduction of current and degrading its performance. As a consequence, probes have to be replaced regularly to maintain proper current flow. The liquid level alarm given here overcomes this problem. A 1kHz AC signal is passed through the probes, so there will be no electrolysis and therefore the probes last longer.

Liquid level alarm circuit

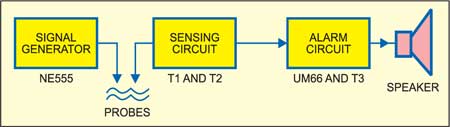

The block diagram for the liquid level alarm is shown in Fig. 1. The signal generator sends the generated signal to the first metallic probe. The second metallic probe is connected to the sensing circuit followed by the alarm circuit.

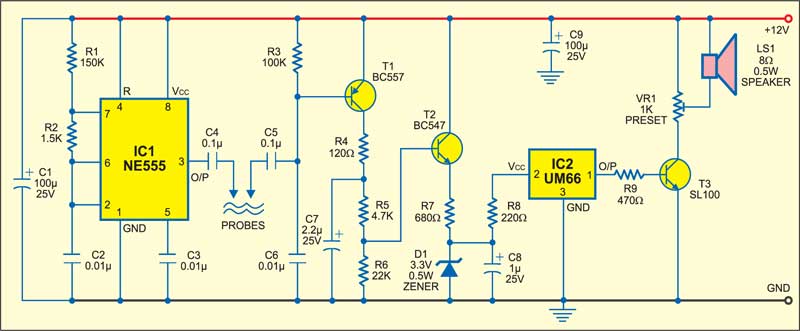

The complete circuit for the liquid level alarm is shown in Fig. 2. The astable multibrator built around IC 555 (IC1) generates 1kHz square wave signal, which is fed to one of the probes via a DC blocking capacitor.

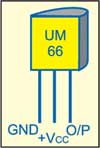

When the water tank is empty, pnp transistor T1 does not get negative base bias. But as water fills up in the tank, it receives 1kHz signal from IC1 via the probes immersed in water and conducts during the negative half cycle of 1kHz signals. Due to the presence of capacitor C7 (2.2µF), npn transistor T2 continues to get base bias and conducts to provide 3.3V DC to melody generator IC UM66 (IC2). Pin configuration of IC UM66 is shown in Fig. 3. Preset VR1 acts as the output loudness controller. It can be varied to set the alarm sound from the speaker at the desired level.

The circuit works off 12V unregulated power and can be used to detect any conductive liquid.

The article was first published in October 2005 and has recently been updated.