Electronic devices feature a large number of small components, each piece being highly important to their overall functionality and safety. The responsibility for ensuring that each minute component is performing adequately rests firmly on the shoulders of the device and component manufacturers. However, their jobs are being made more difficult by the growing issue of counterfeiting in the electrical market.

Printed codes and marks enable manufacturers to track and trace products throughout the supply chain. These also, importantly, help distinguish between genuine and counterfeited components. However, counterfeiters are becoming increasingly sophisticated and have developed capabilities to replicate codes. In order to counter this problem, manufacturers find it necessary to employ more sophisticated coding methods such as smart code techniques.

Smart coding and micro-printing

In today’s rapidly-changing electrical component industry, manufacturers must combine the right technology and techniques to encounter the many obstacles they face.

Electrical components, more often than not, appear to be identical. Coding and marking allows manufacturers to safely make a distinction between parts. Further, coding and marking allow them to build brand recognition into their products.

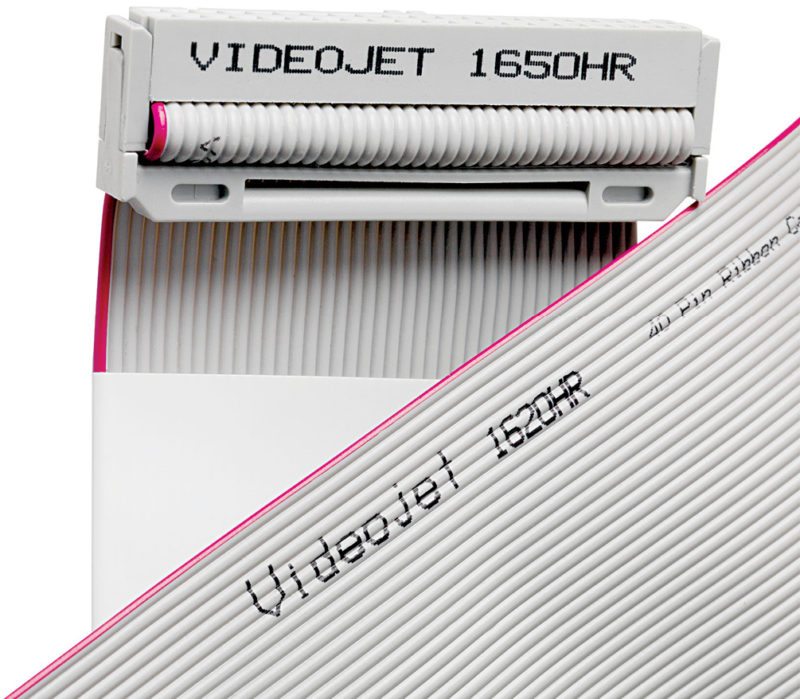

Application of increasingly-complex codes on small surface spaces is a challenge that is hard to overcome with outdated printer technologies. Advanced micro-printers have proved to be the solution. These have the ability to produce high-quality legible text down to 0.6mm in size in high-speed production environments.

Utilising algorithmic software technology, printers equipped with smart coding capabilities can alter and verify specific characters within codes. Implementation of smart coding techniques to improve existing basic lot/batch codes is simple, with nominal incremental production costs. Without knowledge of algorithms and keys, these smart codes are impossible to duplicate and can go a long way towards preventing counterfeiting activities, which contribute to huge profit losses.

Smart coding techniques

There are numerous smart coding techniques that component manufacturers can employ to enhance their basic lot/batch codes. Each technique (explained below) varies in complexity and application:

Self-verifying codes

These are one of the most basic ways to identify the authenticity of products with a visual check. With this type of marking, a pre-determined pattern is set for the code; for example, all digits add up to a certain number.

Interleaved marking

With interleaved marking, characters within a code are partially overlapped. While this overlay is visible to the naked eye, it is highly difficult to replicate this character formulation.

Dynamically-altered font

Varied numbers and letters within a code can have minute sections of characters missing in order to create distinct codes. The advantage of this code is that, visually it is difficult to recognise the small differences—only supply chain partners who have a trained understanding of the code formation can observe the differences.

Verifiable codes

Tracked with vision-inspection systems, verifiable codes utilise unique software-driven algorithms, which cannot be duplicated without an understanding of the algorithm and keys.

Covert codes

Ultraviolet and infrared inks can be utilised to create covert codes that are not visible to the naked eye. Codes are only visible under ultraviolet or other high-frequency lighting, and these are inconspicuous methods of tracking products throughout the supply chain.

Challenges of coding electrical components

Increased productivity and maximised profitability are the main objectives of any production facility, and manufacturers ultimately need to ensure their production line is streamlined in order to safeguard these objectives.

In the electrical manufacturing environment, there are specific challenges related to coding components that the manufacturers must ensure do not interfere with production efficiency. Two of the clearest are limited surface space for marking and coding on small electrical components, and increased complexity of codes.

Given the dynamic nature of modern supply chains, a greater degree of supply chain parties are now demanding that their own specific data is included. This, coupled with anti-counterfeiting coding requirements, means that code complexity has amplified at the same time as components have decreased in size.

Ink durability and compliance are also challenges manufacturers face during the production process. Codes must endure the exacting alcohol cleaning process that electrical components undergo in order to remove solder residue, and need to be durable enough to withstand this process without causing any damage to the components. Further, manufacturers must also ensure that they use halogen-free inks—in line with industry regulations such as Restriction of Hazardous Substance Directive (RoHS).

CIJ, laser printing could provide the solution

Continuous inkjet (CIJ) and laser technologies are perfectly suited to the production and industry requirements of electronic component manufacturing. Both are highly versatile at high speeds and, with smart coding capabilities, CIJ and laser printers’ algorithmic software technologies enable manufacturers to create dynamic codes that are difficult to replicate. Also, both printer technologies have the capability to produce highly-legible complex codes on limited surface spaces.

CIJ printers produce high-resolution codes that are extremely durable, even during exacting alcohol cleaning processes. The technology’s compatibility with alcohol-resistant, quick-drying and halogen-free inks helps to advance coding and marking applications within the electronic component manufacturing environment, and helps manufacturers to comply with legislative requirements. CIJ printers also offer pigmented inks that offer strong code contrast against electronics with dark surfaces.

Laser printers utilise a laser beam that alters the surface of the component and ensures establishment of permanent, traceable marks—from simple codes to more complex graphs. As these printers do not use inks, codes are not affected by the alcohol cleaning processes. Manufacturers have the option of several laser coding methods, depending on the sensitivity of components. New advanced printer ranges offer a variety of laser sources, including CO2, fibre, UV and YAG.

In order to safeguard the quality of codes, manufacturers can use integrated vision systems to verify the accuracy of codes and ensure these are legible for supply chain and distribution partners. These systems can identify whether the contrast in coding is adequate, and help to highlight common coding errors.

Conclusion

Counterfeiting has the potential to create significant profits or losses for companies. This is a real and present issue within the electrical component industry, which can be addressed, in part, through coding and marking applications.

Component manufacturers must also deal with the added challenge of printing increasingly complex codes on small substrate surfaces, and countering these issues with outdated technologies is not a sustainable option. Selecting an advanced CIJ or laser printer with smart coding capabilities can go a long way in assisting manufacturers tackle the problem of counterfeiting, at the same time ensuring maximised production line performance.