All the education in this world would not be able to stop me from burning out parts while working on an electronics project. But being able to reduce the chances of having expensive components go up in smoke would be welcome any day. The option to virtually design electronics has this as one of its many benefits.

We already have exceptionally well-designed software designed to help beginners get started with electronics virtually, without having to directly handle the tools or equipment themselves.

Virtual electronics does not stop there though. It can help you through a number of things from being a platform for collaboration between research and development teams sitting on opposite sides of the planet, to being able to let someone test your chip as part of his or her system without having to give complete access to the component itself [intellectual property (IP) protection].

Creating virtual situations

At Mobile World Congress (MWC) 2015 in Barcelona, two simulators were used to set up a test system that allowed engineers to simulate any global location and mobile connectivity on demand.

Smart Systems Laboratory of University of Hertfordshire, the UK, wanted to demonstrate a connected car and its diagnostics systems in action at MWC. They did this by using a satellite-positioning technology called global navigation satellite system (GNSS) through a simulator from Spectracom. This was combined with simulated long term evolution (LTE) network environment provided by Anritsu’s mobile network simulator. The connected car system being developed is based on the wireless transmission of onboard diagnostics (OBD) information available through a cloud server using mobile backhaul (LTE, 3G and GPRS) together with global positioning system (GPS) location.

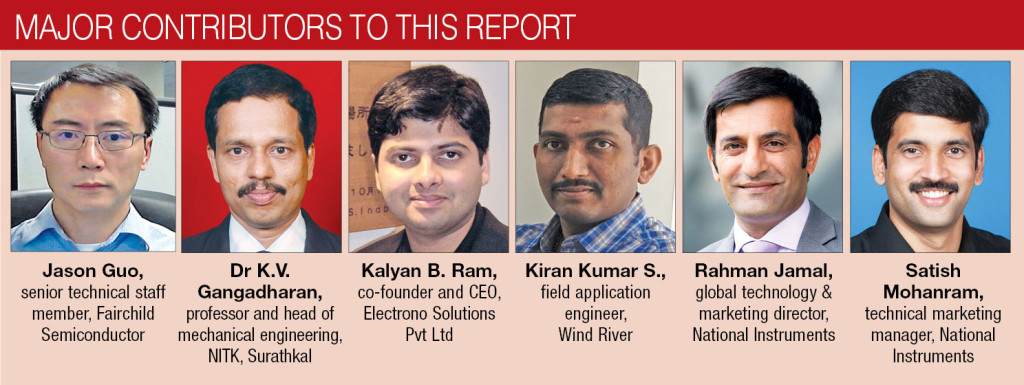

Rahman Jamal, global technology and marketing director, National Instruments (NI), explains that, “As things get complex, say, in a car, for example, you want to do as much engineering as possible in the laboratory where it is safe to test. This is where hardware-in-the-loop (HIL) testing is done. Once that piece of software is running in the loop, it acts as if it was already built. If this test is working out, you can start replacing parts of the simulation with real-built hardware.”

This is something that was known for the automotive industry but it is now being used for white goods like refrigerators and washing machines. We have heard from the industry that integration of simulation capabilities with test is something that they need big time. “While circuit design simulation is a very specific area, this is also done while embedding mathematical models of refrigerators and engine control units (ECUs),” adds Jamal.

A typical network-centric application will have multiple end devices, gateways, switches and routers that are interconnected and generating data as well. When such a system is connected to the Internet, it adds further complications. System simulation tools are able to set up functional virtual platforms for heterogeneous processor architectures and allow devices to be configured on-the-fly.

“Fault injection capabilities can enable the system behaviour to be tested against vulnerabilities, and thereby address security concerns much ahead of time. To rig up such a complex system in a real world would not only have commercial implications but also technical challenges,” adds Kiran Kumar S., field application engineer, Wind River.

The unique IoT design challenge

The Internet of Things (IoT) being a complex cyber physical system with umpteen number of nodes, the biggest design challenge is to ensure reliable and accurate interactions with the real world. Considering the scale at which IoT components would eventually be implemented in, designers have to not just look at whether individual systems work in tandem but also at how it is affecting the overall system when it is finally released into the real-world environment.

“Evolution of a simple design into a complex system is commonplace but we still struggle to manage complexity while accelerating innovation,” according to NI Trendwatch 2014. It adds that this cyber-physical design challenge is amplified when designs span software, networks and physical processes. It also warns that failure to tackle this challenge can result in poor designs and stalled innovation. Using a model based design to design and validate systems will allow engineers to derive models from system specifications and environmental analyses.

Semiconductor manufacturers like Atmel are using engineering simulation solutions from electronic design automation (EDA) vendors like ANSYS to model, analyse and optimise their IoT product portfolio. In a recent release, they stated that Atmel design teams around the world leveraged ANSYS HFSS, ANSYS RedHawk and ANSYS Totem to design and validate these complex systems on chips (SoCs) and platforms used across multiple IoT application segments. These simulation solutions helped enable Atmel to meet stringent power/performance requirements, ensure reliable operations across a wide range of frequencies and deliver products with tight time-to-market constraints.

The report adds, “These modelling techniques illuminate the interplay of practical design with formal models of systems that incorporate both physical dynamics and computation. Manual integration and deployment of these models are costly, time-consuming and error-prone. System design tools with the right levels of abstraction allow cyber and physical models to be automatically combined, simulated and deployed, and the same models are adaptable for requirement tracking and HIL verification.”

Protecting your IP

Ever wanted to provide an early model of an amplifier to your client to ensure that he or she gets to test it in the system simulation and know if the design will win?

X-parameter generators are built to do exactly that. For instance, Keysight’s advanced design system (ADS) X-parameter generator allows you to create a model and request specification changes even before your hardware prototype is ready. It even lets you protect your IP by using Keysight’s PNA non-linear vector network analyser to derive a very accurate model from measured hardware. Your customer can then use this virtual component in his simulation system to see just how well your design works out for him or her.

“Using tools like NI AWR visual system simulator you could either send that component you have designed as a blackbox, or use PXI systems to send signals through this, get the output and just send waveforms. This means that at the other end, you do not have to even see the waveforms. You just have to get these and input these into the system over there,” explains Satish Mohanram, technical marketing manager, National Instruments.

Easier and better R&D

“We have this radio frequency (RF) tool chain that starts with AWR Microwave Office and visual system simulator, which can really help design microwave components and microwave circuitry,” says Mohanram. This means you can design antennae and circuit boards that do all the complex signal processing and generate different waveforms. You could prototype the whole circuit and then certain parts of it can be virtually brought in as models. For instance, if you have built a PCB where all the transmission and reception is going on, you can modify one algorithm in that and optimise it. The benefit of this is that, in the bigger perspective of the system you do not need every component to be ready before you test the whole thing. You can actually have multiple components and then just one component can be refined.

EDA has been well-adopted by chip designers to design and analyse entire semiconductor chips over the last few decades. Jason Guo, senior technical staff member, Fairchild Semiconductor, says, “However, system-level design tools, such as tools for a switched mode power supply design, are not readily available, mainly due to system-level complexities. Recently, some advanced Web based electronic design/simulation tools such as Fairchild’s Power Supply WebDesigner (PSW) have been introduced to enable system-level design of switched mode power supplies.”

These tools are typically driven by knowledge based automation for every decision making point of a design flow, so that even a junior designer can complete a senior-level design in minutes. Web based simulation is used to bridge conventional mismatching gaps between a paper design and hardware performance to further secure a working design.

Announced in February 2015, Altera and Mentor Graphics have teamed up together to provide virtual platforms that contain simulation models of ARM processor sub-systems featured in Altera’s SoC field programmable gate array (FPGA) families. This simplifies embedded software development and reduces the need for expensive hardware by enabling large development teams to perform application development and software regression testing in a virtual environment based on the chip.

Unconventional labs and education

The three kinds of laboratories in Indian engineering institutions are conventional labs, virtual labs and remote labs. In most engineering institutions the laboratory infrastructure is significantly underutilised due to factors such as security, timings and available working days.

Stated in the paper ‘A Distinctive Approach to Enhance the Utility of Laboratories in Indian Academia’ presented at the 2015 International Conference on Remote Engineering and Virtual Instrumentation, authors go on to explain how remote labs can be used to bring awareness about engineering technologies and software in rural schools and colleges in India.

Kalyan Ram B., co-author of the above paper and co-founder and CEO of Electrono Solutions Pvt Ltd, spoke at EFY’s Electronics Rocks 2014 conference on an innovative product named Remote Labs. Essentially a laboratory controlled over the Internet, it is designed exclusively for learning and monitoring any experiment integrated into the college lab. It can also be used by industries for monitoring electronics integrated with the lab.

Another interesting tool is SPARKS (simulations for performance assessments that report on knowledge and skills) software—a virtual lab that targets the beginner side of engineering. It teaches introductory electronics via a virtual breadboard, components and test equipment. The tool monitors, records and interprets student performance. If a student makes a mistake, the computer will point it out; if a critical step was left out, the software will observe and report that too.

Another tool with similar functionality is Sakshat Virtual Labs started by Ministry of Human Resource and Development. The team states at their website that the objective of this lab is to perform virtual experiments in basic electronics and yet have a close-to-real-life experience. The tool is designed in such a way that students get a feel of a real lab, as its equipment, components and behaviour are mimicked by the system.

Virtual Labs and SOLVE

Virtual Labs initiative was set up with the primary objective of experiential learning of the basic concepts in engineering technology and science. It also aims to make the labs available at the learner’s time, pace and place with the aim to make it easier to conduct experiments. The virtual lab set up at NITK, Surathkal, is aptly named SOLVE, an acronym for students online lab for virtual experimentation. NITK, Surathkal, alone has 70,000 users from all over the world at its virtual website (solve.nitk.ac.in), including a few thousand from Pakistan.

While simulation based labs are set up based on a mathematical base, there are also experiment based labs where experiments are conducted and students are given a feel of the data.

Third type is the remote lab, where an actual lab is made available to users through any device connected through the Internet, iPhone, Android or PC.

“Essentially, we are providing a take-home lab where we share costly laboratory equipment through the remote lab infrastructure,” explains Dr K.V. Gangadharan, professor and head of mechanical engineering, NITK, Surathkal.

We have around 100 labs in simulation on the virtual lab website, of which 30 are remote-triggered labs. A remote-triggered lab is an actual experiment at one location to which students can make changes remotely as they interact with the experiment.

The virtual lab provides a complete learning management system, where working principles are taught and knowledge is imparted through textual and video education, which students can apply to their experiments. Various areas covered by these labs include FPGAs and basic electronics. For instance, IIT Delhi has a virtual wireless lab that gives students actual experiments to learn from and keep modifying antennae available to check propagation testing.

Colleges that are interested in accessing this impressive tool can contact the closest college and sign an expression of interest. There are no monetary requirements, and the only facilities needed are to have 25 computers with the Internet facility and decent bandwidth. The existing team will train the faculty and conduct demonstrations. The Centre for System Design is a centre of excellence (CoE) at NITK, Surathkal, which hosts SOLVE Virtual Lab (solve.nitk.ac.in). The national portal for virtual lab is www.vlab.co.in, where about 100 virtual labs are ready to use.

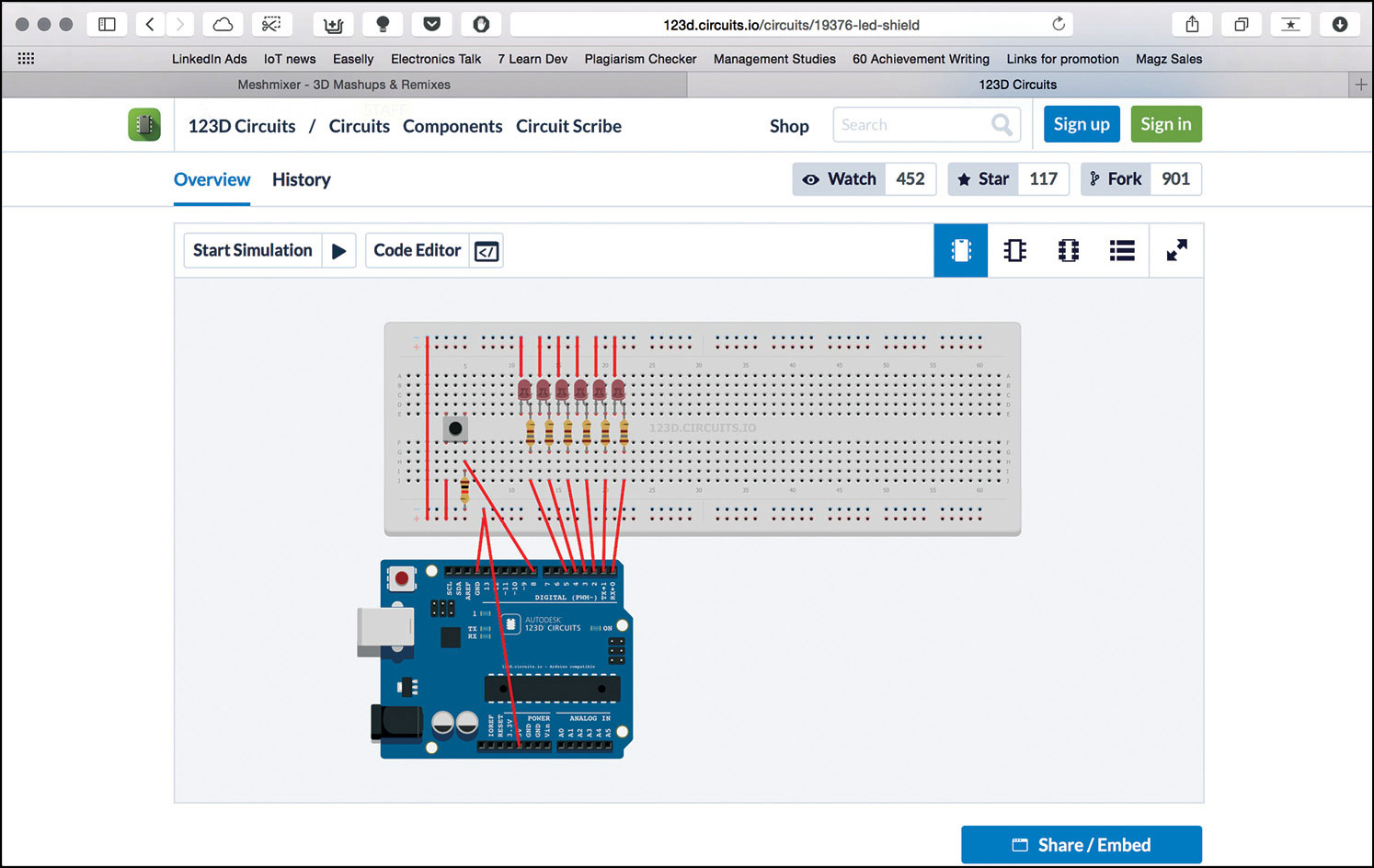

Virtual electronics design through apps

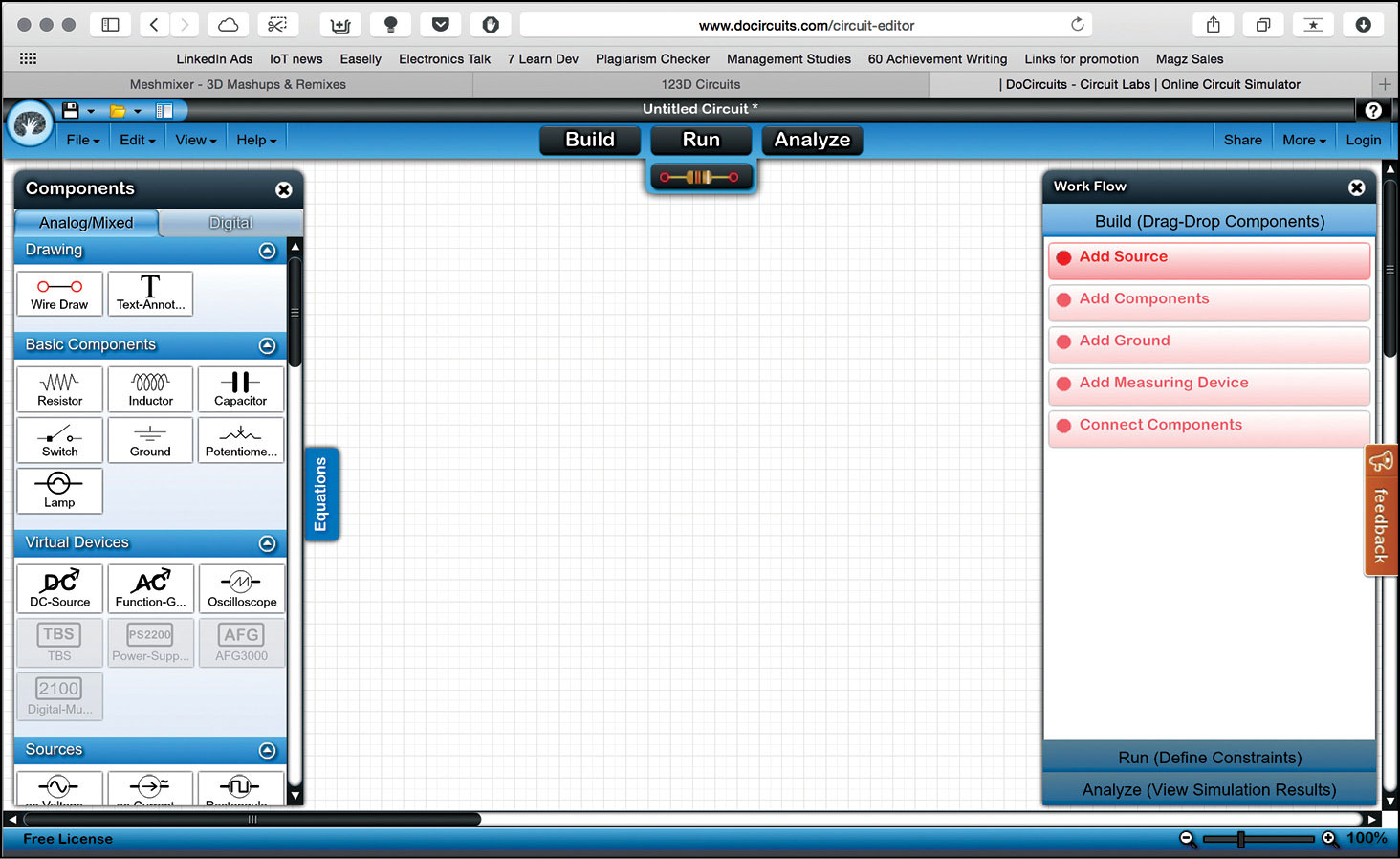

Autodesk has also brought out their own free tool in the form of Autodesk 123D Circuits. Allowing users to design, compile and simulate electronics projects for free without burning your Arduino, it is a great way to get started with electronics design.

An interesting feature of this tool is that it allows users to choose from breadboard, schematic or PCB editor views while working on the design.

In addition to that, the editor allows multiple users to work together as a team, thus making it more fun. You can access this tool at 123dapp.com, where you can also find similar tools for creating 3D models and mashups.

Indian tools are equally amazing in this area. For instance, DoCircuits is an amazing tool built by Bengaluru based Sparsha Learning Technologies Pvt Ltd. It allows you to build circuits, and then test and measure these through lab equipment in a safe simulated environment. Their website docircuits.com allows you to build your first circuit immediately without having to register or go through any of those hassles related with online tools.

If you search deep enough, you can also find browser based design tools that have component supplier integration built into these. For instance, PartSim.com allows you to use its SPICE simulator, AC/DC/transient simulations and waveform viewers to design schematics, which would later be converted into a bill of materials (BOM) by integration with electronic components distributor, Digi-Key.

One particular tool that has received a lot of media attention is CircuitLab, which has been complimented for its user interface and other features like smarter connection lines to connect components, higher-definition schematics and symbol creation, apart from its simulation, plotting and support for behavioural sources and expressions through programmable algebraic sources, which means that you get to play around with programmable voltage and current sources.

If you are looking for branded ones, NI has an electronics workbench that comes with schematic capture and circuit simulation software.

If you are the kind of person who prefers mobile devices like a smartphone or tablet rather than a PC, there are many apps available for simulating circuits too. Ones like iCircuit will cost you Rs. 600 in Apple App Store, but it comes with a ton of features including always-on simulation and over 30 elements that can be used to build your circuit.

In addition to these components, the app also features virtual equipment like multimeters and oscilloscopes to read values or track signals. This app is also available on Windows Store, Google Play and as a Windows Phone app.

What next

With most software development companies going agile, virtual labs and simulation are certainly the most preferred way industries are aligning their software development, debugging, testing, verification and validation. “Simulation results are assisting hardware teams in identifying design issues, thereby reducing iterations. Virtual hardware are also helping support legacy systems, thereby extending the life cycle of products,” adds Kumar.

Next-generation system-level EDA tools will incorporate more in-depth knowledge based design know-how to help engineers at all levels of design expertise to design a switched mode power supply like a power pro. The design tool will complete a design from specifications to schematics and BOM. It should significantly cut design time from a few days/weeks to a few minutes. “This will eventually help achieve ‘first time right’ design through precise modelling and predicting electronic hardware behaviour to further save or eliminate design iteration efforts, especially on the costly hardware-implementation side,” adds Guo.