As electronic devices are evolving to perform more sophisticated tasks, manufacturers are packing as much density onto a chip as possible. However, such density causes reliability problems such as failure stemming from fluctuating temperature cycles as the device operates or fatigues. A failure at any point in the circuit can shut down the whole device.

However, there is only so much you can do to manually repair a modern sophisticated electronic device, as sometimes you cannot even get to the insides of such a device. For example, in a multilayered integrated circuit, there is no way to open it up. Normally, you would just replace the whole chip.

This is true for a battery, too. You cannot pull a battery apart to try to find the source of the failure. Most consumer devices are meant to be replaced with some frequency, adding to electronic waste issues, but in many important applications such as instruments or vehicles for space or military functions, electrical failures cannot be replaced or repaired.

Breaking of materials with minor or major faults in electronic devices leads to their malfunctioning. These material faults can be rectified by an expert technician on the job, but this would lead to a vicious circle of exploitation and might eventually force you to discard the faulty electronic device prematurely. When one tiny circuit within an integrated chip cracks or fails, the whole chip or the whole device is a loss. But what if it could fix itself, and fix itself so fast that you never even know there was a problem?

Electronic materials have been a major stumbling block in the advancement of flexible electronics because existing materials do not function well after breaking and re-making. Electronic devices are subjected to mechanical deformation over time, which could destroy or break these.

Self-healing materials are a class of smart materials that have the structurally-incorporated ability to repair the damage caused by mechanical usage over time. The inspiration comes from biological systems, which have the ability to heal after being wounded. A team of engineers has developed a self-healing system that restores electrical conductivity to a cracked circuit in less time than it takes to blink. Rather than having to build in redundancies or a sensory diagnostics system, this material is designed to take care of the problem itself.

Electronics requirements from self-healing materials

Self-healable materials are those that, after withstanding physical deformation such as being cut in half, naturally repair themselves with little to no external influence. The new electronic material created, however, can heal all its functions automatically even after breaking multiple times. This material could improve the durability of not only wearable electronics but all other electronic devices.

In the past, researchers have been able to create self-healable materials that can restore one function after breaking, but restoring a suite of functions is critical for creating effective wearable electronics. For example, if a dielectric material retains its electrical resistivity after self-healing and not its thermal conductivity, it could put electronics at the risk of over-heating. This is the first time that a self-healable material has been created that can restore multiple properties over multiple breaks—this could be useful across many applications.

Technology fundamentals

Electronic conductivity

Of late, there has been a big research push aimed at developing self-repairing, electrically-conductive materials that can withstand the damage caused by the twisting and deformation of materials. But so far, most of that research has focused on self-repairing electrical conductors. The team previously developed a system for self-healing polymer materials and decided to adapt their technique for conductive systems. It dispersed tiny microcapsules, as small as ten microns in diameter, on top of a gold line functioning as a circuit. As a crack propagated, microcapsules broke open and released the liquid metal contained inside. The liquid metal filled the gap in the circuit, restoring electrical flow.

This is one example of taking the microcapsule based healing approach and applying it to a new function. Everything prior to this has been on structural repair. This is on conductivity restoration. It shows that the concept translates to other things as well. A failure interrupts the current for mere microseconds as liquid metal immediately fills the crack.

The researchers demonstrated that 90 per cent of their samples healed to 99 per cent of original conductivity, even with a small amount of microcapsules. The self-healing system also has the advantages of being localised and autonomous. Only microcapsules that a crack intercepts are opened, so repair only takes place at the point of damage. Further, it requires no human intervention or diagnostics—a boon for applications where accessing a break for repair is impossible, such as a battery, or finding the source of a failure is difficult, such as an aircraft or a spacecraft.Next, the researchers plan to further refine their system and explore other possibilities for using microcapsules to control conductivity. They are particularly interested in applying the microcapsule based self-healing system to batteries, improving their safety and longevity.

Thermal and electronic conductivity

Most research into self-healable electronic materials has focused on electrical conductivity but dielectrics have been overlooked. There is need for conducting elements in circuits, but also for insulation and protection for microelectronics. Researchers have looked at developing a self-healing dielectric material. Dielectrics are just as important as conductors as these provide electronic insulation and packaging.

The material that a research team has created restores all properties needed for use as a dielectric in wearable electronics—mechanical strength, breakdown strength to protect against surges, electrical resistivity, thermal conductivity and dielectric, or insulating, properties.

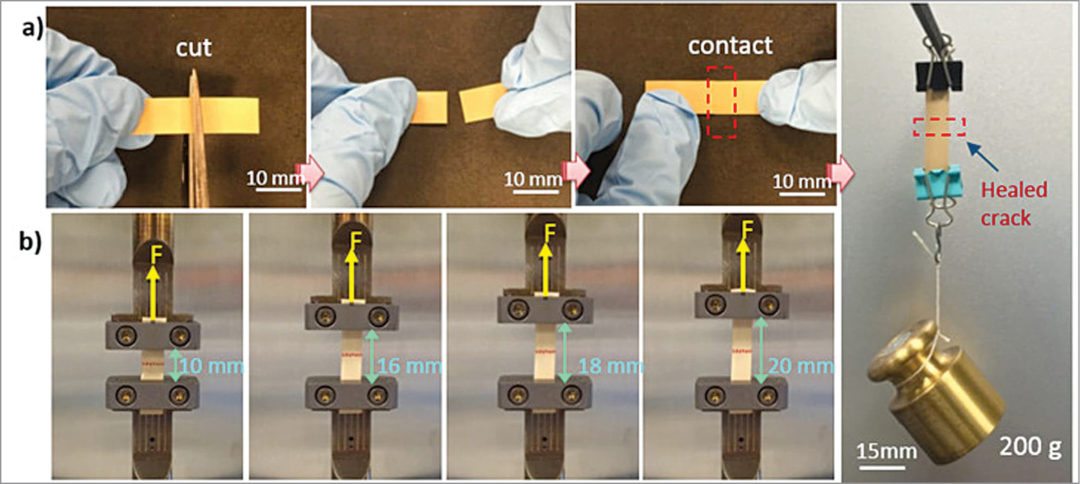

Most self-healable materials are soft or gum-like, according to the team, but this material created is very tough in comparison. The team has added boron-nitride nanosheets to a base material of plastic polymer. Like graphene, boron-nitride nanosheets are two-dimensional, but instead of conducting electricity like graphene, these resist and insulate against it. The material can self-heal because boron-nitride nanosheets connect with hydrogen-bonding groups functionalised onto their surface.

When two pieces are placed in close proximity, electrostatic attraction naturally occurring between both bonding elements draws the two pieces close together. When the hydrogen bond is restored, the two pieces are healed. Depending on the percentage of boron-nitride nanosheets added to the polymer, self-healing may require additional heat or pressure. But some forms of the new material can self-heal at room temperature when placed next to each other. Unlike other healable materials that use hydrogen bonds, boron-nitride nanosheets are impermeable to moisture. This means that devices using this dielectric material can operate effectively within high humidity contexts such as in a shower or at a beach.

Conclusion

In the last 50 years, electronics has grown from vacuum tubes to discrete transistors to micro-chips with thousands of transistors together in an area the size of the head of a pin. The trend for ever smaller electronic devices continues even today. As electronic devices grow ever more intricate, so must the tools required to fix these!

Electronic circuits are very sophisticated these days, but a crack, even an extremely small one, can interrupt the flow of current and eventually lead to the failure of a device.

Traditional devices can be fixed with soldering, but repairing advanced electronic devices requires innovation. Replacing whole devices or even parts can be tricky or expensive, particularly if these are integrated in clothes or located in remote places. Creating devices that can fix themselves would be ideal.

Anticipating this challenge, scientists have turned to the body’s immune system for inspiration and are now building self-healing electronic materials that would restore all their functions after a material breaks. These self-healing electronic materials can seek out and repair faults in electronic systems.