‘’I fear the day that technology will surpass our human interactions. The world will have a generation of idiots.’ – Albert Einstein

The Paris Agreement on climate change is now the basis for many decisions on the manufacturing processes and systems that should be followed all over the world. While industry at large slowly moves toward the implementation of green technology, international militaries cannot be left behind in the race to adopt this technology. Certain ambitious targets have been set by the Paris Agreement, in terms of lowering energy consumption, reducing our dependence on fossil fuels and slashing carbon emissions. Across all verticals, the adoption of more environment-aware manufacturing processes is referred to as green manufacturing.

Today, India’s armed forces are the third largest in the world and their combined expenditure is the eighth largest defence budget, globally. In 2016, on World Environment Day, the broad outline of how to reduce the carbon footprint of the Indian armed forces was chalked out. The Indian Navy recently created an energy and environment cell, which is tasked with making it an environmentally responsible force — not only energy and resource efficient, but resilient in terms of energy costs and disruptions. The main aims of this mission are energy conservation, diversification of energy supplies and minimising the impact on the environment.

These aims are being achieved by using cutting-edge technology and state-of-art equipment, which are energy efficient and have a low carbon footprint. Mass energy conservation drives have become the norm, driven by this cell. Regular mentoring sessions are held across the commands and repair stations, to continuously educate and sensitise personnel on the importance of energy and environmental conservation, and to make environment consciousness a way of life. These initiatives have borne fruit, with significant savings to the tune of Rs 15 million to Rs 200 million annually, per naval base station.

The Defence Institute of Bio-Energy Research (DIBER), a DRDO lab based at Haldwani in Uttarakhand, has developed a bio-diesel from a plant called Jatropha Curcas, which is a blend that includes 20 per cent normal diesel. Trials for this have been successful on ships like the INS Shivaji. And now, with the inclusion of the bio-diesel powered fast interceptor combat vehicles, the progress in this new direction is encouraging.

An overview of the changes

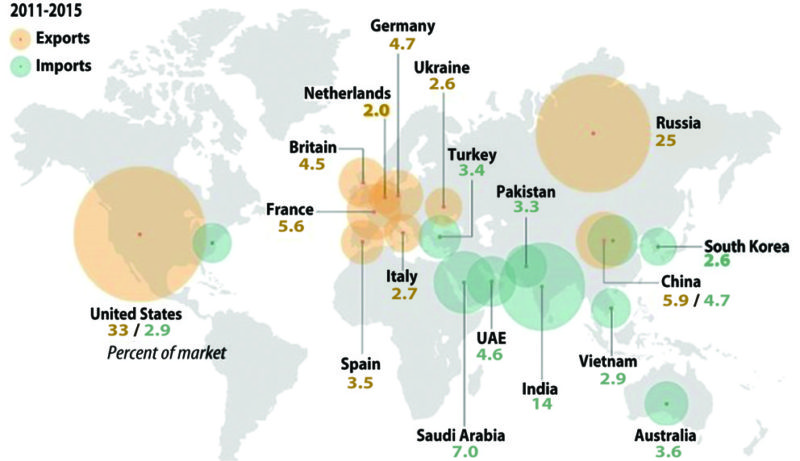

India today accounts for 14 per cent of global arms imports (see Figure 1 for global details), and 2.4 per cent of the country’s GDP is spent on defence. With the increased threats at our borders, the spend on defence is slated to touch 7-8 per cent of the GDP in the next five years. That’s the reason why Make in India is critical for the defence sector in times to come. In the process, traditional manufacturing methods would need to give way to lean and green options, even while improving the bottomline for businesses. Capital investment estimates for India’s defence sector over the next five years hint at a figure of US$ 250 billion, with 53 per cent invested in the Army, 23 per cent in the Air Force, 16 per cent in the Navy, 6 per cent in defence R&D, 1 per cent on ordinance factory development and the remaining 1 per cent on other miscellaneous activities.

India today gets nearly 70 per cent of its defence requirements from abroad, but that’s slated to change with the new directives coming into force. And with the FDI level opening up to 49 per cent, the sector is surely going to see changes, with projections that Indian manufacturing for the defence sector will grow from 15 per cent of the total market to 25 per cent within five years.

So let’s look at the major products that are being made in India for its armed forces today, by adopting indigenous and green processes that have a focus on reusability.

Sonar dome:

India has joined a select group of countries that have the capabilities to manufacture the sonar dome. This dome is attached to the bottom of ships, and scans the seas for submarine threats. The manufacturing requirements are technically demanding.

The R&D for this project was done at Pune, by the DRDO lab under the aegis of Research and Development Establishment Engineers (RDEE). The dome was manufactured by Kineco Ltd, a composites manufacturing facility in Goa. The other critical component in the design, Vacuum Assisted Resin Transfer Moulding (VARTM), was also successfully manufactured in India. The developments shown in this regard stand to benefit the land based and aerospace applications in the future.

Varunastra torpedo:

This underwater missile has been developed by research scientists at the Naval Science and Technological Labs (NTSL) in partnership with the Hyderabad based PSU, Bharat Dynamics, with a defined road map from creation to commissioning. And 2016 was the year when this initiative turned into reality. At the time of its launch and commissioning to the services, Manohar Parrikar, the then defence minister, stated: “In these high technology areas, DRDO’s contribution with 95 per cent of indigenous content is an apt example for a product from the ‘Indigenously Designed Developed and Manufactured’ category.” The torpedo is an important milestone in pushing India towards self-reliance when it comes to underwater defence capabilities. Our current lot of submarines and warships will now be equipped with these new torpedoes, which will make them a potent force for the future. The capability of these torpedoes extends to knocking down stealth missiles in deep or shallow waters, if the situation demands it.

Tejas:

This light combat aircraft has been jointly developed by Hindustan Aeronautics Limited (HAL) and Aeronautical Development Agency (ADA). The aircraft can take up a variety of roles in war situations and is supersonic by nature. It took around 3000+ sorties to demonstrate the capabilities of this LCA prior to it being inducted into the Indian Air Force. Speaking at the launch of the Tejas fighter, Prime Minister Narendra Modi stated that the LCA demonstrated India’s skills and strengths in enhancing indigenous defence manufacturing. The Tejas is capable of firing air-to-air missiles, and can drop laser guided bombs. And most information gathered during sorties can be captured in real-time by the inclusion of a high-resolution display in the cockpit.

Long range surface-to-air missile (LRSAM):

This missile has been jointly developed by DRDO and the Israel Aerospace Industries, to complement the capabilities of the MRSAM (medium range surface-to-air missile). Last year, in September, LRSAM was tested on two pilotless target aircrafts, at different ranges and altitudes. And both exercises were successful. Among the versatile technologies used in the LRSAM are the radar guidance system, the communication system and the missile system.

Evaluating the lack of private sector participation in defence manufacturing

Private manufacturers lack the incentive to enter the defence sector because of a number of reasons. These include the risk on returns due to the rigorous checks in the sector, a stringent and ambiguous policy framework, irregular orders, lack of demand and the non-feasibility of small orders, the scarcity of resources and skilled manpower to meet the sensitive requirements of the sector, etc. These problems are made worse by the lack of economies of scale in production and the long gestation periods. There is also a feeling in the private sector that there isn’t a level playing field vis-a-vis the public sector. This is because of the lopsided rules of the government and the incentives that are provided to the public sector units in terms of vast infrastructure, investments, technology collaborations, etc. In short, in the current scenario, private players find manufacturing for the defence sector unsustainable.

With the defence sector at an inflection point, the government must take the necessary steps to bridge the gap between its intentions and the ground realities. Considering the potential of this sector, the government should assume more responsibility to boost its efficiency and ensure fair play, by creating strong policy frameworks while keeping the security aspects in mind.

The way forward

Considering the various aspects of the defence sector, here are certain recommendations for getting the private players more involved in manufacturing for this sector.

1. Policy simplification:

As of today, the sector is governed by varied policies that cover licensing, import and export duties, security checks, tax regulations and procurement. The controls and restrictions imposed on the players operating in an uncertain and unclear legal framework affect efficiency and productivity. The bureaucratic delays add to the challenges, affecting the inflow for foreign investments. All government policies must be harmonised and synchronised towards a single window clearance with prefixed turnaround times (TATs) and a smooth operational framework, which would aid in ease of doing business.

2. Tax holidays:

The government of the day should consider extending benefits to defence manufacturers by giving the sector an infra status, wherein it can enjoy 100 per cent tax subsidy for a stipulated number of years, and cut down the import duties on capital expenditure. This will help strengthen the base of the manufacturing industry.

3. Inclusive development:

The ministry must address the industry demands, and provide advanced infrastructure and functional funding in terms of prototyping finance for SMEs, ensure ongoing and regular orders, give R&D support and help in absorbing the risks on returns since defence manufacturing involves low volumes. Government policies should help in attracting angel investors to this sector, and the outsourcing model must be worked upon, whereby PSUs involve the SMEs. The overall idea is to balance out investments against the profits for the sector.

4. Fostering strategic partnerships:

The recent government policy where foreign investors need to have a strategic Indian partner is a step in the right direction. More bold steps in this direction must be thought of to create a better ecosystem to boost domestic participation. The key is to ensure that all necessary steps are taken to capitalise latent resources and technologies, develop requisite skillsets in individuals and not shy away from foreign collaboration wherever required.

I do hope these insights make an impact in the corridors of power and provide an understanding to business entrepreneurs as they enter the defence sector. But before I end, I would like to put a question to all of you — is it prudent for India to build talent now or wait till the industry achieves economies of scale? I ask because our neighbour China has followed the path of first creating the infrastructure for manufacturing, and then focused on creating the skillsets for working on it. Should India follow the same model, or focus on both aspects together, or focus on creating the talent pool first? This is food for thought, and I would love to hear from you on this.

I have been receiving some very good responses in this journey of writing on green technology, which have been inspiring me to research and write more on the subject. The research has also helped me build quality interactions with various industry leaders. If you have any questions or suggestions in this regard, feel free to write to me at [email protected]; I shall be happy to respond. Till the next time…