McLaren-Honda, manufacturer of premium electric racing cars, recently started using silicon-carbide (SiC) power devices in inverters and on-board chargers, which increased their efficiency by 1.7 per cent while also reducing the cooling system size by 30 per cent. Thus, a change in the power component not only made their inverter compact but also rugged for use in electric cars. Similarly, gallium-nitride (GaN) power devices increase the reliability of low-power products.

“Both SiC and GaN-based power-conversion devices are creating a difference and making the product rugged,” says Niranjan G., general manager (business development & technical marketing), ROHM Semiconductor.

Ruggedising electronic hardware: external and internal

A hardware system needs to be electrically as well as physically rugged so that it can withstand harsh environmental conditions, electrical faults, component failures, mechanical faults, etc.

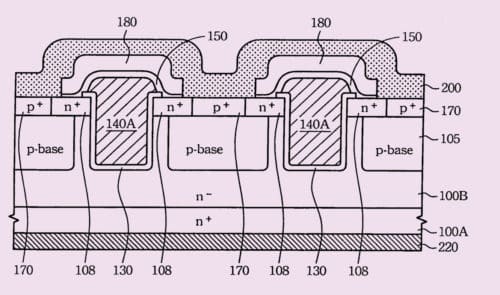

Fig. 1: SiC and GaN market analysis (Image courtesy: www.pntpower.com)

For instance, for LED luminaires, designers select LED devices based on the application requirements of lumens, life-time, intensity and colour temperature. Optical component selection is also based on the application. Power supply is designed keeping in mind the desired current, voltage, power input, total harmonic distortion (THD) and power factor. Mechanical part is based on the thermal dissipation of the luminaire as a whole.

Besides, designers follow various manufacturing standards that are important from ruggedness point of view. LM79 standard is followed for LED luminaire performance test, and LM80 for LED evaluation. IPXX standards are followed for protection of LED luminaires and power supply from environmental conditions such as air, water, dust, physical contact and accidental contacts. IEC, EC, UL and BEE standards pertain to the quality of a hardware product.

The hardware includes the PCB and components on the PCB. Be it an analogue solution, power solution, sensing solution or mobile solution, hardware must be well-built and rugged.

Analogue and power solutions

There have been industrial upgrades in the quality of the PCB, power components and their hardware applications at electrical or physical level.

PCB and improved substrate

The PCB is an essential element of a hardware as it provides the base or the platform to the circuitry. The PCB material is chosen based on the type of application. For instance, as a small power supply with less input and output current will dissipate very less heat, it can be built on an FR4-based PCB, which costs very less.

Hrishikesh Kamat, CEO of Shalaka Connected Devices, says, “Multilayer boards have been prepped up to 256 layers by tech giants.”

As electronic devices shrink, PCBs are becoming smaller and multilayer to support connectivity with several components at a time. Complexity of the circuitry is increasing and the technology is getting sophisticated. The average thickness of the PCB ranges between 0.5mm and 0.7mm, which, technology experts believe, will decrease further to 0.4mm or less. This will open up new possibilities in the wearables domain.

Traditionally, PCB prepregs have been fibreglass or epoxy, but now substrates are available in several other materials too, such as resin-coated copper, resin-coated film and liquid-crystal film. These prepregs maintain the signal integrity of a circuit and high-end processing at low costs.

Thus, improved PCB substrate and reduced PCB thickness ensure high signal integrity and low output losses, resulting in a reliable and rugged hardware.

Smaller, stronger, faster components

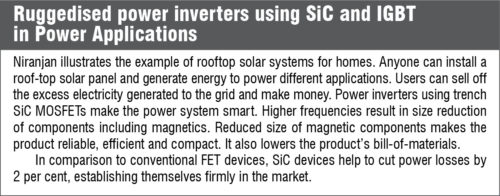

Silicon carbide is becoming the industry-leading technology in power conversion, contributing to the eco-friendly environment. ‘Trench-structure’ design contributes to the long-term reliability of components. Nowadays, these trench-structure MOS devices are acting as alternatives to relays in automobiles (especially electric vehicles) due to their high current handling capability. Their other field applications include industrial automation equipment, solar power inverters, digital power supplies of large-scale servers in data centres and home appliances such as air-conditioners.

For low-power and medium-power applications, trench-structure devices provide many advantages:

1. Structural change lowers the drain-to-source resistance (RDS ON) and thus heat dissipation, making the end product efficient

2. Breakdown voltage and switching frequencies of trench-structure MOSFETs and other components using SiC are generally higher than conventional FETs

3. Low on-resistance, high breakdown voltage, high current and high frequencies enable a compact and efficient cooling system

4. The compact size of the component helps in reducing the size and the cost of the PCB

“Thus, silicon carbide reduces the overall system costs and helps in energy conservation by making efficient end-products,” says Niranjan.

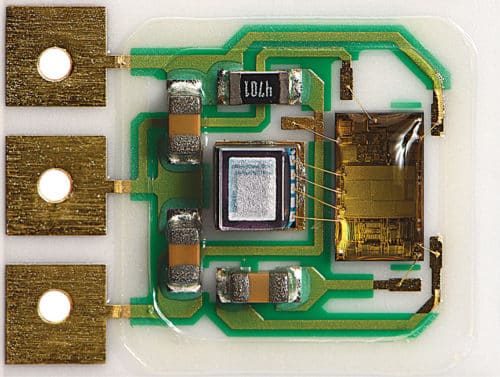

Fig. 2: Trench power MOS in SiC device (Image courtesy: patentimages.storage.googleapis.com)

Chip resistor—no more laser cuts for accurate value

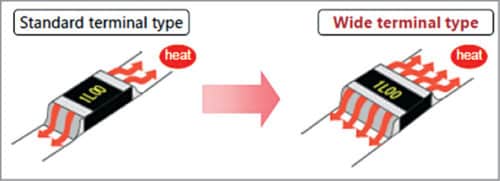

Niranjan says, “Thermo-mechanical stress causes resistor failure, so manufacturers are coming up with a techno-logy that allows solder application on the lateral side of the resistor chip.”

Chip resistors’ solder area on their lateral side assists them to sit well on copper pads, avoiding short-circuit and open-circuit faults and breakage due to thermal and mechanical stresses. This helps the resistors to remain cracks-free for a long term.

As far as the manufacturing of chip resistors is concerned, earlier laser cuts were carried out to adjust the resistor value. With that method, usually, the resistor value did not exactly match the customer requirement. Now the practice of laser cuts in resistors has been discontinued, which allows resistor values according to specifications.

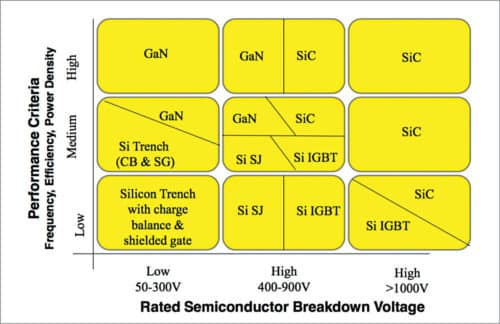

Fig. 3: Wide terminal configuration for high joint reliability

Thus, current flows much easily through a component without traces of burns. Change in the structure has increased the reliability and ruggedness of the chip resistor.

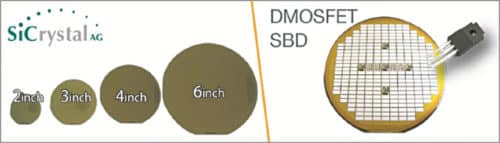

Increase in the size of the SiC substrate

The size of the SiC substrate has increased from 5cm to 15cm. The increased size (15cm) is being used in countries like Germany since 2014. It helps in churning more number of different SiC devices, reducing wastage from the leftover substrate. Hence, the reliability of a component extracted out of the substrate increases.

Fig. 4: The increased substrate size (15cm) helps in churning more number of devices

Sensing solutions and mobile solutions

Smart applications, including mobile applications and their components, and networking applications and their hardware, have been customised at the embedded level.

MEMS sensors

Kamat says, “MEMS sensors and nanotechnology are next-level technologies in the industry.”

MEMS sensors are being used widely in mobile divisions, smart automation systems, imaging systems and microphone applications. Advanced driver-assistance system (ADAS) in automobiles accounts for the largest market. It combines accelerator, gyroscope and speedo-meter in one system to give an error-free, compact solution, saving the large area which each of these functions used to cover through the driving circuitry and wire mesh.

MEMS sensors make the hardware system of automobiles rugged as well as reliable. Kamat cites the example of sensor-based wheels, wherein MEMS sensors inform the driver about a fault in advance, preventing accidents. Automobile giant Tesla has converted its electric car system to sensor-based. Thus, while no use of fuel reduces the chances of pollution, the sensor-based technology ensures fast and reliable functioning.

Talking about wearables, SOLI sensors are taking the market by storm. These sensors easily recognise 3D gestures expressed with the help of fingers and hands. Low-bandwidth application and small size of SOLI sensors make these a reliable component for wearable devices.

Fig. 5: MEMS pressure sensors

Networking protocols reducing the use of wired connections

Smart city, a project picking up pace worldwide, relies on the Internet of Things (IoT) wireless network system. Wireless system is believed to replace the LoRaWAN and NBIoT system. Thus, the use of sensor technology and wireless network has made it possible for the future technology to gear up and increase the bandwidth.

Low latency, high bandwidth, long life-cycle and low power consumption make WiSUN a reliable network protocol that is easier for the enterprises to accept over time due to its fail-safe communication.

Lithium-polymer battery replacing Li-ion battery

Since electric cars have become the next-generation vehicle, designers are focused on increasing the longevity and ruggedness of their batteries.

Compact size and low weight are making lithium polymer batteries the future trend. Due to their large current-carrying capacity, these batteries can be charged several times without delay. This makes them a reliable input component of mobile phones.

Kamat says, “Lithium polymer batteries supply a large current and are compact in size, which makes these affordable for smartphones.”

Testing the hardware ruggedness

Hardware ruggedness testing includes testing of the hardware against extreme temperatures, shock and vibrations, and other environmental conditions. When a product is designed, it is passed through various harsh test conditions in order to confirm its quality and reliability.

After design phase, the product undergoes test and analysis, where it is checked thoroughly for its electrical, mechanical and physical properties.

Ruggedness is a critical feature for wearables, sensors, power supply devices and components. If manufacturers are careless during design and development phase, the end-product would neither be reliable nor be able to create its value in the market.