Microwave sensors offer great advantages in security and energy savings with their high sensitivity

Microwave sensors are cost-effective solutions to save energy expenses and secure premises of businesses. Their most popular use is in lighting, where these can save up to 40 per cent of electricity expenditure for companies.

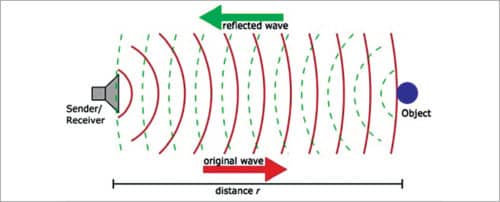

Devices containing microwave sensors generate microwave rays, which cover a certain area across the space. When a person walks into the microwave zone, his body causes the waves to reflect, which is detected by the sensor for further action. Occupancy sensors, in particular, are quite popular. These use infrared or microwave technology depending on the application.

Let’s explore how microwave sensors benefit businesses.

Cuts energy bills by half

Electric appliance control is a popular use case of microwave sensors. Microwave sensors can cut a substantial amount of energy wastage by automatically turning the lights off when an area is unoccupied.

Lal Changlani, director, Sensinova Lighting, comments, “Microwave sensors can save 30-80 per cent of electricity expenses depending on the frequency of motion in the area and the mode of energy usage. Areas with more intermittent occupancy will generate more savings. For instance, corridors and staircases have intermittent traffic throughout the day. The time during which these areas remain unoccupied will generate complete savings.

Additionally, many places have lights running in staircases and corridors even at night between 10 pm and 5 am. These expenses can be completely cut down with an automated control. Nowadays, microwave sensors enable auto-dimming of lights, further optimising the energy charts for businesses.”

Rajath Rao, managing partner, Ecoamica Technologies, shares an example of microwave sensors usage: Kuwait-based Baiti Synergy was experiencing high electricity costs for its office space. The main reason behind excessive energy consumption was office cubicles being lighted even when these were unoccupied—both during and after office hours. Baiti installed microwave sensor solutions from Ecoamica in office cubicles, cabins and other areas of its workspace. The sensors themselves consumed 1.1 watts, running 24 hours a day. Energy audit after a few electricity billing cycles revealed a steady cost reduction by 30 per cent and very quick payback on the investment.

Provides tight security

Security applications require very sensitive devices to pick up even the slightest of movements in closed areas. The consistent emission of microwave rays makes it impossible for intruders to pass undetected. An active coverage of up to 120 metres sets off the alarm the moment thieves, burglars and intruders enter the premises.

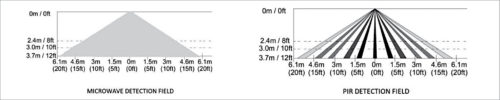

Rajath explains, “Microwave sensors have heightened sensitivity due to the presence of fewer dead zones in their detection field. Hence these are used for detection of very little movements. They find a lot of use in security applications such as intrusion alarm systems for closed-environment spaces of offices.”

A spokesperson from Pyrotech Electronics shares, “Microwave sensors detect any motion even beyond walls or behind doors. Warehouses with restricted-access areas, banks or rooms with lockers use microwave sensors for the same reason. Any motion across the restricted area, even if it is behind doors, gets detected and the alarm sets off.”

Industrial applications

Conventional sensor solutions to measure the performance of industrial devices are quite expensive. Additionally, these require regular maintenance and adjustments, resulting in some downtime. Microwave sensors provide benefits like high interference immunity, one-time servicing and tuning for lifetime operation, high precision and high reliability. Many industries are installing microwave sensors to monitor the functions of bucket elevators and belt conveyors.

Wadeco, a Japan-headquartered industrial microwave sensor manufacturer, provides microwave sensors for crane proximity detection. These sensors are used to ensure a safe distance between two cranes working on the same line or between a crane and a building or landing station close-by. City municipalities use microwave sensors to monitor wastewater and sewage levels in sewage lines.

Even medical science is leveraging the low-power properties of microwave sensors. A lot of R&D is underway to come up with non-invasive treatments in medical applications like breast cancer treatment, separation of red blood cells from white blood cells and liver tissue disease detection using microwave sensors.

Challenges with microwave sensors

Microwave sensors have a large coverage range, and their waves penetrating through walls or glass also poses challenges such as false alarms. For instance, when used for lighting control in small office floors, the sensors may switch on the lights even if someone is outside the premises. The high sensitivity of microwave sensors will also detect the non-human presence, like animals or some fast-moving objects in the air. On the other hand, microwave sensors cannot reach beyond any metal obstruction.

Are PIR sensors better?

Often, passive infrared (PIR) sensors are used as an alternative to microwave sensors. However, their performance differs owing to the underlying technologies.As mentioned earlier, microwave sensors have a higher sensitivity and coverage range than PIR sensors. Changlani explains, “Since PIRs read infrared heat signatures in a room, these are not very sensitive if the room itself is warm. Therefore, in warm countries like India, PIR sensors at times may not be able to detect a person, especially in summers. On the other hand, during winters, these sensors become highly sensitive.”

Snoozing is another challenge with PIR sensors. Even on occupied floors, PIR sensors may turn off even if there is very little movement. A little body movement instantly turns these on again.

Moreover, thieves may find it easier to fool the PIR detection range. Rajath explains, “Microwave sensors offer a distinct advantage over PIR sensors with a continuous field-of-detection zone. PIR sensors have a slotted detection zone. Therefore PIR sensors may miss out objects in their detection zone.” This makes microwaves a better proposition for security.

However, microwaves have higher false alarm rates. Moreover, these are slightly costlier than PIR sensors and consume more energy. Rajath explains, “Microwave sensors typically consume 30 per cent more energy than PIRs. While PIR sensors consume 0.8-1.0W electricity, microwaves take 1.1-1.5W. Microwave sensors may start from ₹ 600 and go up to ₹ 1000. These cost 20 per cent more than PIR sensors.”

Overall, PIR sensors are good for electrical applications in smaller and compact premises. Microwave sensors are suited for large-area security applications.

The best results can be achieved by installing both the technologies in a complementary fashion. For example, California’s North Bay Vaca Valley hospital invested in a lighting setup transformation for their 225 parking spaces in 2014. The investment included 50 induction luminaires with LED fixtures. PIR sensors and long-range microwave sensors were installed in dedicated zones to save electricity when these areas were not in use. Smart controls were also put in place. The annual audit of this setup reported a 14,600-kilowatt-hour reduction in energy consumption, which cumulated to 65 per cent electricity savings. There were annual savings worth $2300 with the help of these sensors complementing each other.