Availability of real-time data and reliable transmission from the sensor to the receiver are crucial for medical, nuclear and autonomous vehicle applications. This article details how sensors meet the requirements of such applications.

Sensing technology is evolving at a very fast pace with miniaturisation of microprocessors, embedded systems and other modules, especially micro-electromechanical system (MEMS) sensors. Many embedded sensors have been incorporated into traditional and existing sensor node platforms. These embedded sensor nodes are often physically small and relatively inexpensive computers, each with some set of sensors or actuators.

Embedded sensors are actually part of embedded computers placed in the physical real world that interact with the surrounding environment. With modern hardware advances in sensors and software components, embedded sensors are an active and growing area of embedded computing, and one can witness their expanding applications in many areas.

For example, embedded sensor module MICA2 Mote is a popular wireless measurement system used for enabling low-power, wireless sensor networks. It supports 868/916MHz, 433/315MHz multi-channel transceivers with extended range. It can be interfaced to measure light, temperature, RH, barometric pressure, acceleration/seismic, acoustic, magnetic and other parameters.

Critical applications

Mission-critical applications require safe computer architectures, including the Internet of Things (IoT) with predictable failure behaviour, to avoid financial loss as well as damage to people and the environment caused by equipment failure. Mission-critical computer architectures used in railways or avionics are complex and include safety-critical characteristics, reliability, error-behaviour modes, safety integrity levels and various other standards. There are also dedicated development, validation, production and qualification processes.

Mission-critical, time-critical and safety-critical applications require fast identification, timely action, reliable notification and warning messages.

The context and levels of criticality may vary from industry to industry but there are some parameters common to all such applications involving sensors. Availability of real-time data and reliable transmission from the sensor to the receiver are important in critical applications. In these applications, data received after the expiration time will not only render something useless but also negatively impact the decision made by users. Good quality, longevity, high sensitivity and reliability are prerequisites for sensors to deal with such critical applications.

This article covers some sensors used in critical applications such as medical, nuclear and autonomous vehicles.

Medical sensors

A medical device is used to diagnose, monitor or treat diseases, or as a supportive aid for physically disabled persons. Various types of sensors are used in medical applications, including temperature probes, force sensors in kidney dialysis machines, airflow sensors in anesthesia delivery systems, and pressure sensors in infusion pumps and sleep apnea machines. Implanted pacemaker is a real-time embedded sensor system that delivers a synchronised rhythmic electric stimulus to the heart muscle in order to maintain an effective cardiac rhythm.

Medical devices are segmented into different classes. For example, in Canada, Class I devices present the lowest potential risk and Class IV devices the highest potential risk. Implantable pacemakers are high-risk devices because if the device fails, it costs a precious life. Sensors/electrodes of pacemakers detect the heart’s electrical activity and send data through wires to the computer. So, these are life-saving and safety-critical medical applications of sensors.

Device malfunctions exist and it’s often difficult to pinpoint the exact cause. For example, if a pacemaker fails, the reason could be equipment failure or changes in the patient’s native heart rhythm. Sometimes inaccurate data due to incorrect placement of the device on the body could seriously affect the results of diagnosis. Errors can be significantly reduced with the right approach and good-quality product design. Sensors for medical devices must comply with safety, accuracy and reliability standards laid down by the regulatory bodies.

For example, IEC 60601-1 medical device safety standard establishes general requirements for safety and performance and is the global benchmark for medical electrical equipment.

Apart from IEC 60601, statutory specifications for medical devices include other enforcement and standards for quality management, risk management, usability and functional safety to ensure that a given apparatus functions correctly in response to inputs.

Good-quality sensors complying with safety standards provide greater accuracy and reliability to patient care. For instance, high-volume pressure sensors from Freescale Semiconductors and airflow sensors from Honeywell are intended for use in medical devices.

Freescale’s MPX2300DT1 high-volume pressure sensor with integrated thin-film temperature compensation and calibration is based on piezoresistive technology. It is intended for use in medical diagnostics, infusion pumps, blood pressure monitors, pressure catheter applications and patient monitoring. It can be interfaced with an embedded system.

Honeywell’s Zephyr digital airflow sensors featuring precise measurement, fast response time, high accuracy, high stability and high sensitivity are suitable for critical medical applications like anesthesia delivery machines, laparoscopy and heart pumps. These support ASIC-based I2C digital output, which allows easy integration to microprocessors or microcontrollers.

Nuclear sensors

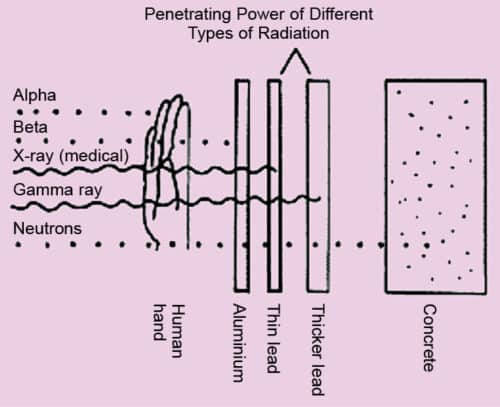

Alpha, beta and gamma rays, as well as neutrons are the most common forms of ionising radiation. Workers in nuclear power plants receive low doses of radiation. Noting that exposure to high levels of ionising radiation can cause cancer, Atomic Energy Regulatory Board (AERB) prescribed the radiation dose limit for workers. Nuclear Power Corporation of India Limited (NPCIL) has strict procedures in place to keep radiation doses to workers within limits. Therefore radiation doses received by workers are recorded and monitored regularly.

Recent nuclear disaster in Japan has raised awareness about risks from nuclear radiation and created an additional demand for commercial as well as personal radiation detection devices.

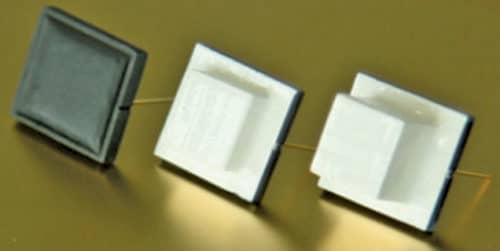

Sensors and detectors play a major role in ensuring safety of nuclear plant workers. Nuclear particle sensors have been already developed to detect radiation types. Instead of tubes and chambers for nuclear particle detection, a variety of solidstate sensors are available today. Solidstate sensors directly convert the incident radiation into electrical current using materials such as silicon, germanium and cadmium zinc telluride. These sensors have high energy resolutions, which makes them suitable for detecting the exact amount of radiation energy. Alpha, beta, gamma and X-ray radiations can be detected using silicon PIN photodiodes.

Generally, solidstate radiation detectors can be divided into scintillator-based and direct-absorption-based detectors. Scintillator-based detectors provide better radiation detection but these are costlier. Direct-absorption detectors based on silicon are a reliable and inexpensive alternative. For example, First Sensor AG has developed a PIN diode based X100-7 direct-absorption detector for nuclear applications. Ultra Electronics, NSPI, USA, also designs and manufactures sensors for safety-related and critical measurements in nuclear power plants.

Autonomous vehicle sensors

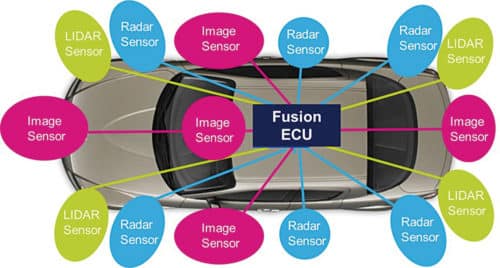

Safety, fast identification, timely action, reliable notification and warning messages are of prime importance in autonomous vehicles. These are monitored and controlled by embedded MEMS sensors used in autonomous vehicles. Embedded sensor systems include cameras, radars, light-based radar (LiDAR) systems, ultrasonic sensors, wheel-speed sensors and global positioning systems (GPS).

Camera

Cameras and radar systems are prerequisites for all levels of automation. Using image sensors, cameras provide information like speed, distance and outlines of obstacles and moving objects. Autonomous cars use rear, front and 360-degree cameras. Cameras help the driver with a better representation of the surrounding and environment outside the vehicle.

Normally, four to six cameras are required to obtain realistic 3D images. Front camera systems are used to automatically detect objects within 100-250 metres. The algorithm in cameras can identify pedestrians, motor vehicles, side strips, road margins, etc. These can also detect traffic signs and signals. A good dynamic range of the camera is required to provide clear image even when sun rays are falling directly onto the camera lens.

Radar

It is used for detection and localisation of objects using radio waves. Advanced driver-assistance systems employ many radar sensors making an important contribution to the overall function of autonomous driving. Many radar sensors and modules are already available in the market. For example, STRADA770 single-chip transceiver from STMicroelectronics is available in FO-WLP 230 package for automotive radar applications. It operates in the 76-81GHz frequency band. Another popular chip is Infineon’s 24GHz BGT24MTR11 for radar front-ends.

LiDAR

It is a laser-based system primarily used to measure distances to stationary as well as moving objects. It calculates the distance of an object from the moving car. It employs special procedures to provide 3D images of the detected objects. The system is a complex mechanical mirror system, normally mounted on top of the autonomous car, which captures spatial images of objects with 360° all-round visibility.

Wheel-speed sensor

It is used to determine the speed at which the car is moving. Usually, it consists of a toothed ring and magnetic pickup used by anti-lock brake systems, traction control and other systems to indicate wheel speed.

Ultrasonic sensor

These are used for parking and detecting objects very close to the vehicle.

GPS

It provides the information for accurate positioning and location of the car.