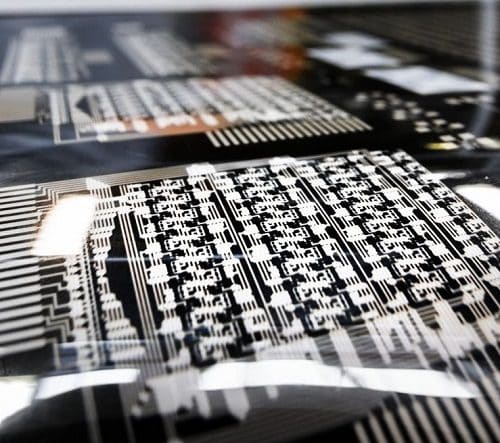

These printed large-scale integrated circuits are made of a special conducting material that can do fast processing and the printing ink allows extremely fine micrometre connections to be made with ease.

When it comes to printing sheet(s) of paper, we don’t bother much as the machinery to do so is already existing. But when a conversation topic on printing an entire integrated circuit comes up, we wonder about the possibility of achieving this task and whether it will effectively work or not – just like a conventional integrated circuit.

Now a team of researchers from Linköping University, Sweden and RISE, Campus Norrköping, Sweden have made it possible by successfully printing integrated circuits, which consist of more than 100 organic electrochemical transistors.

“The advantage is that we do not need to mix different manufacturing methods: everything is done by screen printing and in relatively few processing steps. The key is ensuring that the different layers end up in exactly the right place”, said Peter Andersson Ersman, researcher in printed electronics at the RISE research institute.

Transistors on an A4-sized substrate

A material called PEDOT: PSS or Poly (2,3-ethylene dioxythiophene) polystyrene sulfonate was used. It is conductive and widely used in screen printing processes.

“We now use the same material in the integrated circuit, which makes it possible to print more efficiently”, said Magnus Berggren, professor of organic electronics and director of Laboratory of Organic Electronics (LOE).

The ink deployed to print these integrated circuits helped in creating thin lines for providing adequate spacing between individual transistors so that the entire circuit can do processing at a fast rate. Not only did this improve the quality, but it also helped miniaturise the final product.

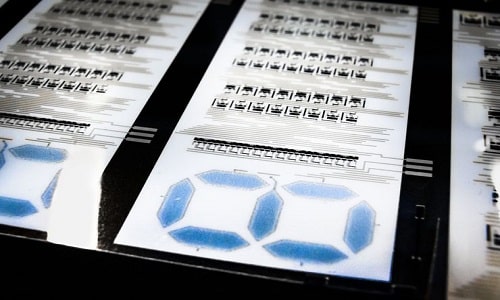

“We can now place more than 1000 organic electrochemical transistors on an A4-sized plastic substrate, and can connect them in different ways to create different types of printed integrated circuits”, said Simone Fabiano, head of research in organic nanoelectronics in the Laboratory of Organic Electronics.

Berggren further added that traditional silicon-based electronic components have been well integrated with these printed circuits. One of these was a shift-register that formed a functional interface between a silicon-based circuit and sensors/displays. This meant that silicon chips with fewer contacts could be placed in a small area.

These large-scale integrated circuits (LSI) have many applications such as powering an electrochromic display or manufacture IoT-based printed electronics products.

Challenges and overcoming them

Printed electronic circuits with a thickness of approximately 100 micrometres call for the finest printing technology and printing ink. To meet these demands, the researchers developed screen printing frames with meshes that can print extremely fine lines.

Getting sufficient funding for this ambitious project was another issue. Fortunately, several organisations like the Swedish Foundation for Strategic Research, Vinnova, the Knut and Alice Wallenberg Foundation and the EU gladly stepped in to provide assistance.

As of now, challenges with respect to size, signal processing and funding have been successfully dealt with. It is now to be seen how these ICs will fare as compared to the ones we have grown used to and how they can enhance our own projects

Read the original research paper here.