Cheap unregulated soldering irons do not have any kind of thermal regulation. These directly plug into the wall socket and heat up to a high temperature while sitting in the holder. There is some amount of natural thermal regulation in such soldering irons but that is due to the physical environment; the more the tip gets hotter, the more heat it dissipates, and similarly the more it cools down, the less heat is dissipated. These soldering irons may be described as thermally balanced but the output is neither controlled nor stable.

Temperature controlled soldering stations

Such soldering irons heat up to high temperatures, so the initial soldering occurs at way too high temperature, which leads to poor-quality soldering and possible damage to the components. With temperature controlled soldering stations, you can set the temperature beyond the melting point of your specific solder but still within a safe limit for the components. Especially, with SMD packages, using too high temperature or holding the iron for too long in position (because of inefficient heat transfer) may damage them.

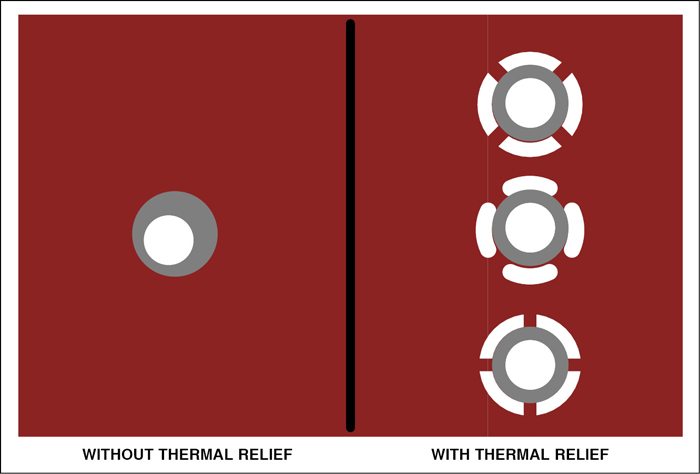

When the soldering tip touches the joint, its temperature drops as the heat is dissipated in the joint. If the part you are soldering can dissipate heat at a rate more than what your soldering iron can deliver, the temperature will keep dropping until it can’t melt solder any more. This is normally the case when you are soldering components on the power planes with improper thermal relief or thick joints.

Fig. 1 shows the different thermal reliefs. These are normally required with power planes. If there is no thermal relief, the heat is dissipated at a high rate due to the larger surface area. The tip cools down rapidly and the joint is dry soldered. Temperature-controlled irons are useful in such a case as these can dump extra power into the bit without increasing the temperature. An uncontrolled iron will simply cool down. This also means that you would need different wattage irons to do a PCB if you are using unregulated irons. With a temperature-controlled soldering iron, you can easily adjust the temperature corresponding to the requirement of different joints.

So the conclusion is: Never go for cheap unregulated soldering irons. These will prove to be more expensive than temperature- controlled irons one day and you will regret it.

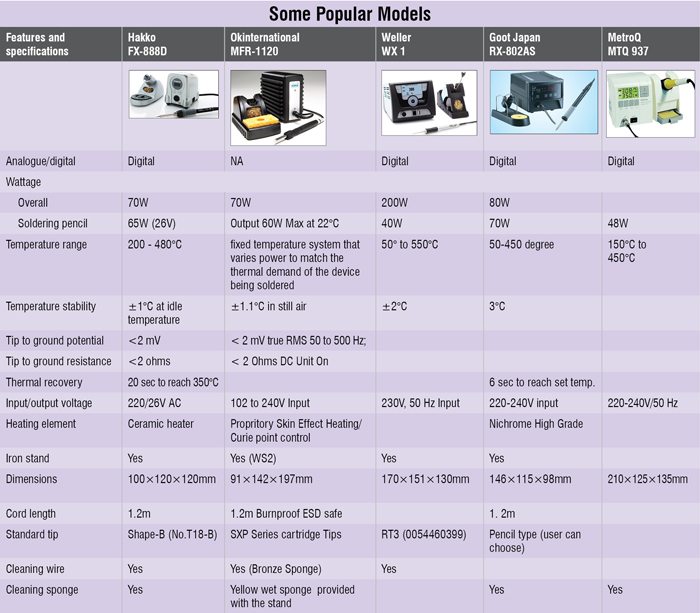

Now let’s find out how to select from the right temperature controlled soldering stations available. To decide, carefully check the specifications mentioned below and consider the recommendations.

Specification recommendations

Analogue or digital? A soldering station consists of a soldering iron whose temperature is controlled through an electrical power supply. The control may be as simple as a variable potentiometer, or little more advanced like a microprocessor based control. The potentiometer type roughly sets the temperature of the soldering station. The microcontroller based type controls the temperature at the heating element using the reading from a thermocouple and heats the tip according to the user-defined settings.

Analogue or digital? A soldering station consists of a soldering iron whose temperature is controlled through an electrical power supply. The control may be as simple as a variable potentiometer, or little more advanced like a microprocessor based control. The potentiometer type roughly sets the temperature of the soldering station. The microcontroller based type controls the temperature at the heating element using the reading from a thermocouple and heats the tip according to the user-defined settings.

Digital vs analogue refers to different ways of telling you about the tip temperature. Digital looks more professional and can actually read in finer increments. However, such precision is not really required and it has nothing to do with the type of iron. Therefore choose the digital one only when you really need it, as it is expensive.

Wattage

The wattage that you would require completely depends on the project in hand. Usually, bigger components absorb and dissipate more heat. If this rate is more than the power of the soldering iron, it starts cooling down. So the general rule is that you need more wattage for larger parts.

Typically, power rating of 15-25 watts is sufficient for most electronics work. A higher wattage does not mean that the iron runs hotter—it simply means that there is more power in reserve when required. If you are just soldering small components and ICs, 15 watts will be fine, but you may have to wait a bit in between joints for the tip to recover its temperature. If you are soldering larger components, especially ones with heat sinks (like voltage regulators), you will probably need a 25W or 30W iron. For soldering larger things like 10-gauge copper wire, motor casings or large heat sinks, you need a soldering iron with 50W or higher rating.

Take a higher-wattage iron considering future requirements too. For large components and joints, you would need more power and you would not like to change your iron every time.

Input/output voltage

Carefully check specifications of the soldering iron that you want to buy. Most irons run from the mains at 240V. However, there are soldering irons available that run with 120V supply too, which will not be suitable for India. If you are buying the soldering station from an authorised distributor, the one with 120V will obviously not be available in India. But some people make this mistake when they buy online from websites. Therefore do check the input/output voltage range.

Temperature accuracy

Temperature accuracy means how closely tip temperature comes to the temperature that you have set at the station. There are several reasons due to which the temperature at the tip and the one set by you always differ. Sometimes designers compromise on accuracy to make the equipment cost effective. Also, the tolerance for each component affects the accuracy to a great extent.

The size and shape of the tip also affect the accuracy, which can be explained by laws of thermodynamics and heat transfer. Tips lose heat by radiation, convection and conduction. The part that does the work is conduction and the other two are parasites. If the tip is thick with more surface area, it can retain the heat better than long, thin ones.

The accuracy of ±5°C is good enough for any electronics work.

Temperature stability

This is a measure of how well the control circuit works, allowing heat loss to the environment.

Stability specification is valid only when the iron is at rest, not when it is actually used for soldering.

Thermal recovery

This too is a measure of how well the control circuit works. When a joint is soldered, heat is lost from the tip through conduction and the tip’s temperature drops. Thermal recovery means, how long a soldering station will take with a particular tip at, say, room temperature, to get back to the initial temperature. The better the thermal recovery, the faster the operator can work.

Tip-to-ground potential

Tip-to-ground potential is also called ‘millivolt leakage.’ This is the voltage existing between the soldering iron tip and the workstation common point ground. It should not exceed 2 mV as defined by various standards.

Tip-to-ground resistance

This is the resistance between the tip of the soldering iron and the workstation common point ground. It should be 2 ohms to 5 ohms.

Insulation resistance

The resistance between the soldering iron tip and its heating element is known as insulation resistance. Also called ‘isolation resistance,’ it is actually a measurement of the isolation of the tip from the secondary winding of the transformer.

Anti-static protection

For soldering static-sensitive components, you need an anti-static soldering station.

Advanced and expensive soldering iron stations use static-dissipative materials in their construction to ensure that static does not build up on the iron itself and damage the components when soldered. Such soldering stations are tagged as ‘ESD safe.’

Regular soldering stations will not be ESD-safe but these can perform reasonably well in most cases if you take the usual antistatic precautions when handling components. The tip needs to be well earthed (grounded) in such a case.

Selecting the right tip

Selecting the right tip, depending on the type of the project, is of utmost importance. The right tip will get you efficient and good-quality results. There are several types of tips available. The most common and widely used tips are mentioned below:

Chisel tips

Chisel tips are one of the most widely used tips. For most soldering jobs, a chisel tip will work the best. It provides you a tapered edge that can fit between most components with a flat tip that facilitates heat transfer.

Conical tips

This type of tip is cone shaped. It is perfect if your project has hard to reach places.

Conical tips should be used only when there is need to get into tight areas. These do not have as much contact area with the component as chisel tips. They require larger contact time with the component to solder the joint.

Pyramid tips

Pyramid tips too are very useful for small components that are mounted at hard to reach places. These have the benefit of a flat side, which makes heat transfer faster and easier. Pyramid tips are a very good alternative to conical tips.

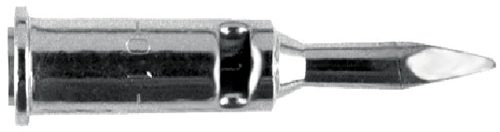

Bevel/single flat tips

Bevel tips give the advantages of both chisel and conical tips. A bevel tip is made with a flat edge together with a round edge on the tip. You can use the side suited to your project. While selecting such a tip, take care that both sides are of correct size for your project. Having the round and flat parts together can save money.

Blade tips

Blade tips are wider than most tips. These tips are highly useful for rework and pad levelling applications.

Selecting the right tip size

There are plenty of sizes available for each type of tip. Carefully select the tip that easily fits between components on the board. Do check the components that you want to solder and choose a solder tip of correct size and shape. If your tip is too narrow, it will take much longer for the component to heat up and may damage the component. An extra wide tip may be less efficient in heat transfer and may resist heat transfer.

Feel interested? Check out other guides.